Method for building waste tyre sand resisting dam and waste tyre sand resisting dam

A waste tire and sand blocking technology, applied in dams, buildings, embankments, etc., can solve problems such as secondary pollution, and achieve the effects of fast transportation, fast processing, fast and flexible assembly and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

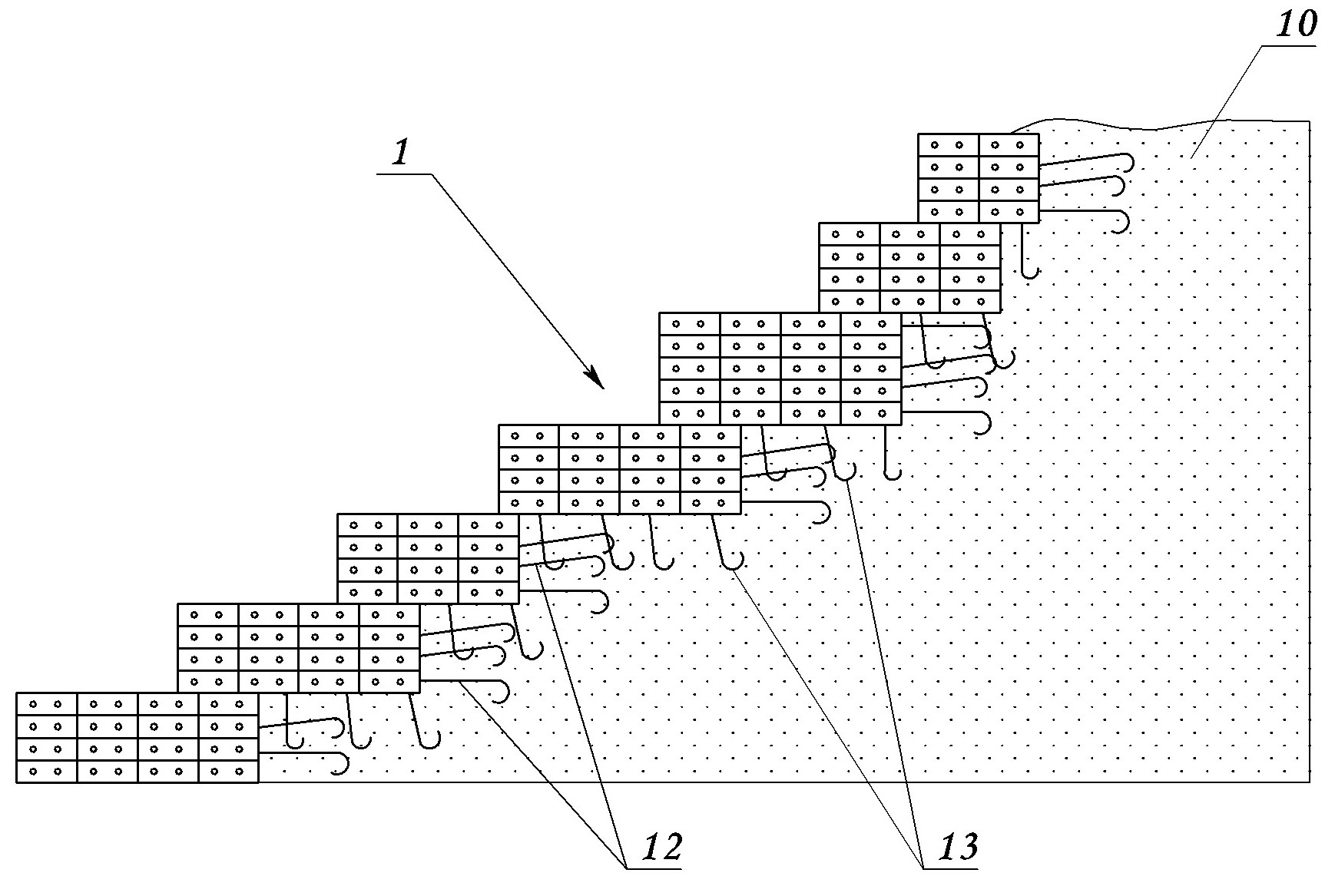

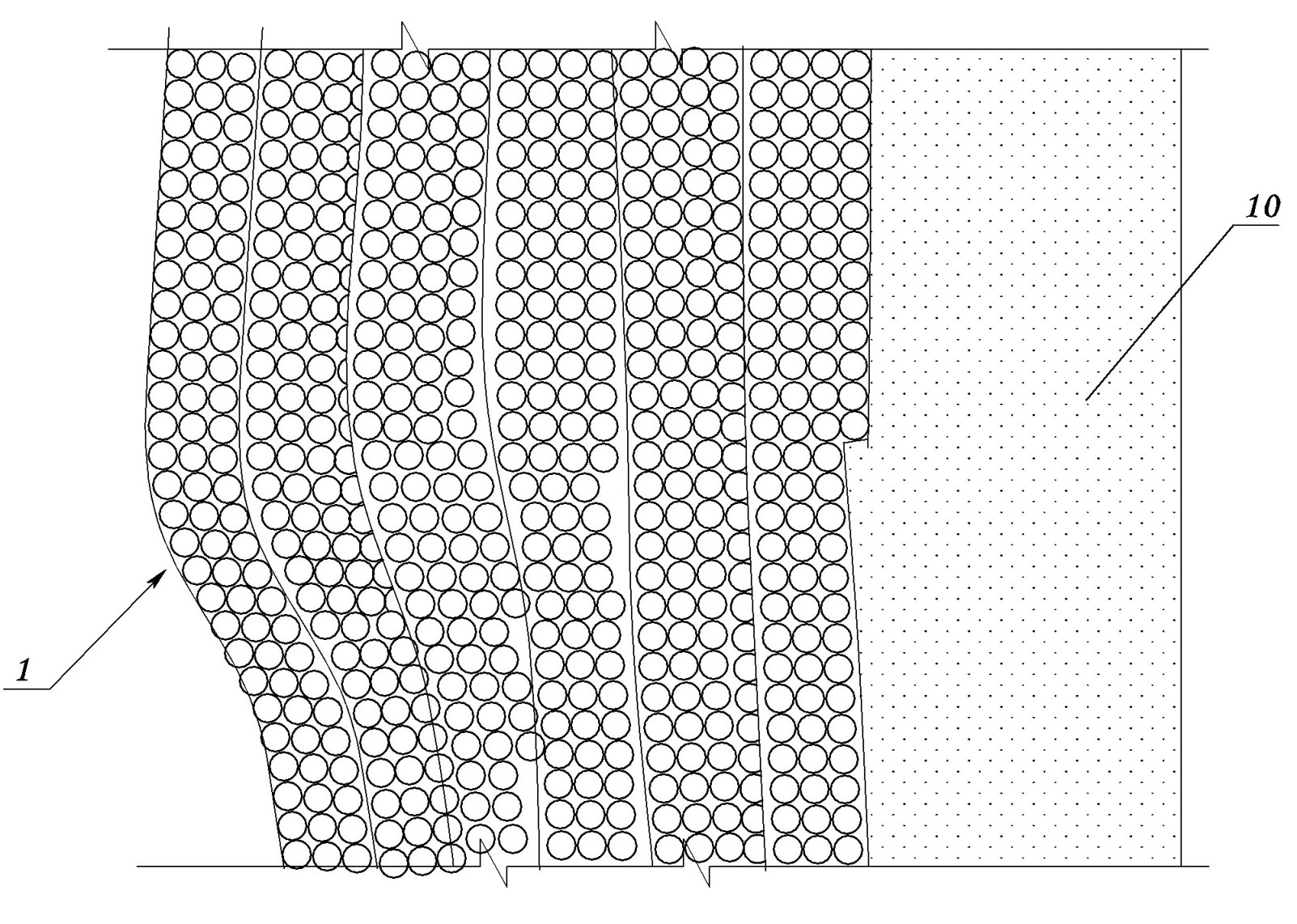

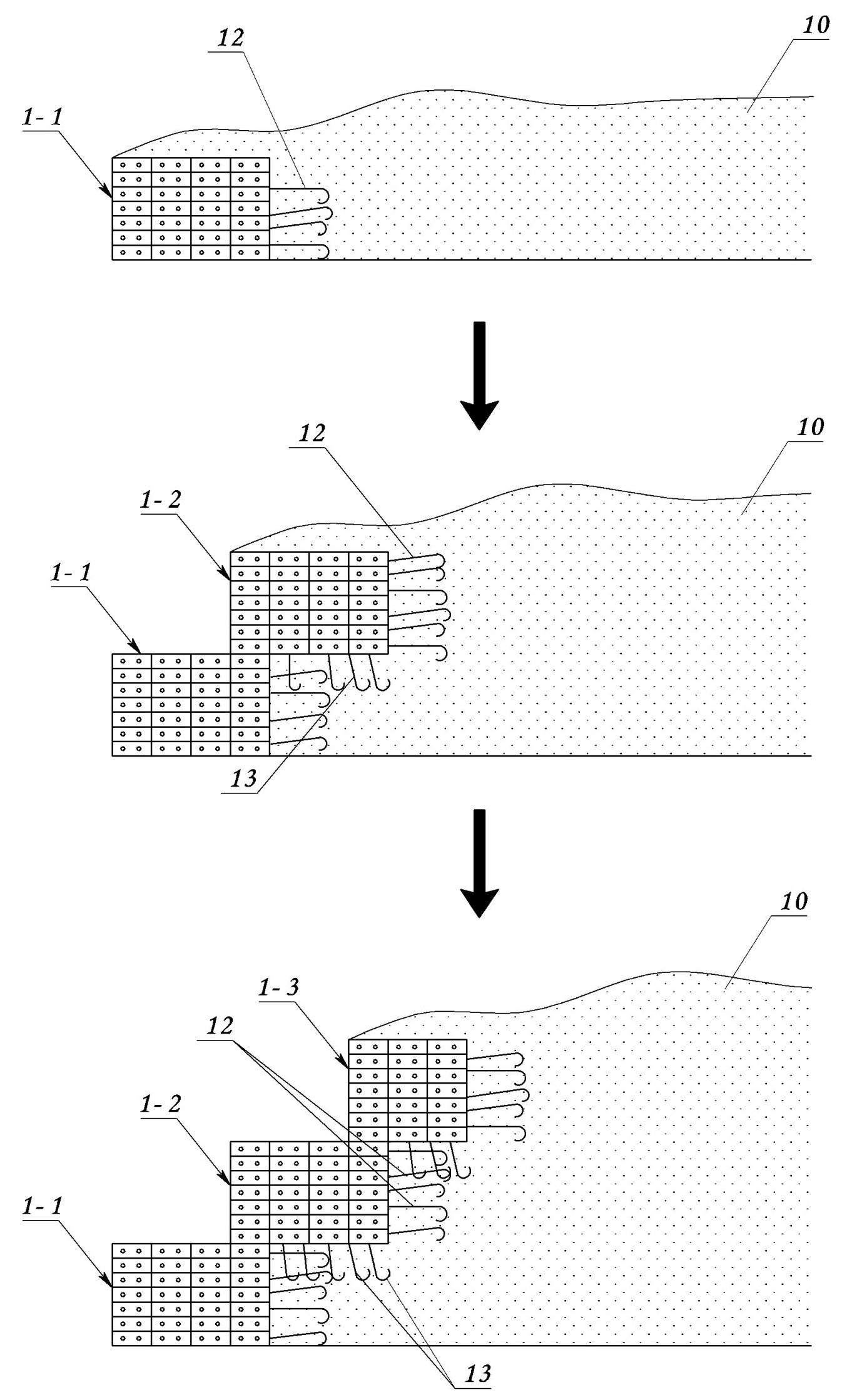

[0045] Embodiment one: see figure 1 — image 3 , Image 6 with Figure 7 , a method for forming a waste tire sand blocking dam and the waste tire sand blocking dam, comprising the following steps:

[0046] (1) After clearing the sand in the defense area, first use waste tires to form the first layer of waste tire sand-blocking layer 1-1. The first layer of waste tire prestressed mesh is composed of a plurality of waste tire prestressed belts; the waste tire prestressed belt is a belt structure formed by a plurality of waste tires butted laterally in sequence, and is worn in each waste tire. into parallel steel strands 3, and the two ends of the steel strands are respectively fixed on the outer edges of the outermost tires at both ends after the steel strands are prestressed; It is a network structure formed by sequentially butting in the longitudinal direction, and the longitudinally parallel steel strands are inserted into the longitudinally adjacent waste tires 2. After ...

Embodiment 2

[0052] Embodiment two: see figure 1 — image 3 , Image 6 with Figure 7 , the content is basically the same as that of Example 1, and the similarities will not be repeated. The difference is that in steps (2) and (4), when sorting out the height of the sand body behind the sand-blocking layer of waste tires, including The compaction process of the side sand body.

Embodiment 3

[0053] Embodiment three: see figure 1 — image 3 , Image 6 with Figure 7 , the content is basically the same as that of Embodiment 1, and the similarities will not be repeated. The difference is that two adjacent sand-blocking layers of waste tires can be connected together by a fixing piece. The connecting piece can be a fixed hook or an iron wire or the like. In order to facilitate the rapid docking of the upper and lower sides, half of the butt joint surfaces between the upper and lower layers are provided with guide columns 9, which is convenient for quick positioning after hoisting.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com