Grape branch pulp

A grape branch and pulping technology, which is applied in the field of grape branch pulp, can solve problems such as waste of resources, and achieve the effects of high production efficiency, reliable production process, and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

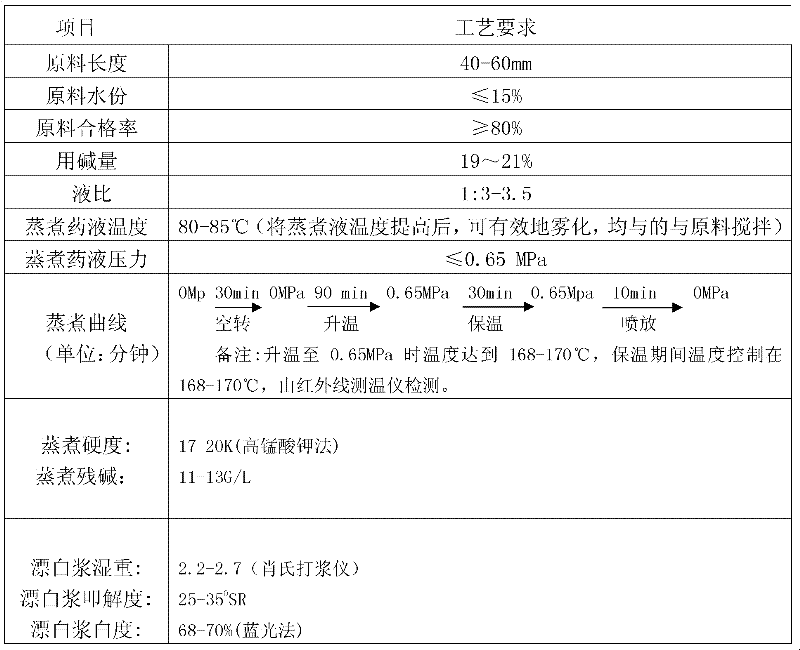

[0016] The present invention uses grape branch as raw material, adopts caustic soda pulping process, the caustic soda pulping process is the same as the conventional caustic soda pulping process in the prior art, and its process includes material preparation, cooking, spraying, rough screening, pulp washing, screening, Dehydration and CEH three-stage bleaching.

[0017] The specific process is:

[0018] The exported grape branches are sent to the cutter roller mower through the belt conveyor for cutting. The cut grape branches enter the dust collector for dust removal and impurity removal. After that, it enters the pre-soaker and the cooking liquid for out-of-ball pre-soaking. Grape shoots and cooking liquid are mechanically potted through potners after pre-soaking in pre-soakers. The current process implements one-time charging, and after the cooking is completed, it is sprayed by the spray pot. Finally, CEH three-stage bleaching is carried out after preliminary screening...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com