Blended color dyeing method of fabric

A fabric and dye technology, applied in the field of textile printing and dyeing, can solve the problems of fiber damage and loss, affecting the fullness and firmness of finished fabrics, and achieve the effect of good fullness and firmness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

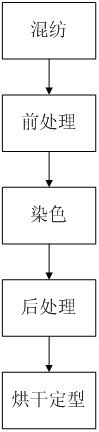

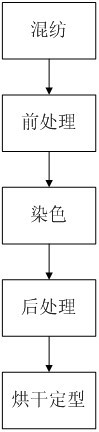

Method used

Image

Examples

Embodiment 1

[0026] Gray fabric: Regenerated fiber containing naphthol dye pretreatment agent and bleached cotton fiber are blended at a ratio of 50:50.

[0027] Dyeing process: first pre-dye the gray cloth, and then add red naphthol dye to the bath solution for dyeing, dye the regenerated fiber containing naphthol dye pretreatment agent in the gray cloth red, and the cotton fiber is undyed white , the gray cloth shows red and white mixed colors, and then the dyed cloth is post-treated, such as color fixing, washing, etc., and finally the post-treated cloth is not dried and shaped to get the finished product.

Embodiment 2

[0029] Gray fabric: Regenerated fiber containing naphthol dye pretreatment agent and bleached cotton fiber are blended at a ratio of 50:50.

[0030] Dyeing process: Compared with Example 1, the main difference is that red naphthol dye is added for dyeing, and yellow direct dye is added for dyeing after 30 minutes, and the gray cloth presents red and yellow mixed colors after dyeing.

Embodiment 3

[0032] Gray fabric: Regenerated fiber containing naphthol dye pretreatment agent, cationic regenerated fiber and bleached cotton fiber are blended according to the ratio of 30:20:50.

[0033] Dyeing process: first pre-dye the gray cloth, then add red naphthol dye to the bath solution for dyeing, add navy blue cationic dye for dyeing after 30 minutes, and dye the regenerated fiber containing naphthol dye pretreatment agent in the gray cloth Red, cationic regenerated fiber is dyed navy blue, while cotton fiber is undyed white, the gray cloth shows a mixed color of red, navy blue and white, and then the dyed cloth is post-treated, such as color fixing , washing and other treatments, and finally the post-treatment is not dried and shaped to get the finished product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com