Method for heating and controlling temperature of coke oven

A coke oven and coking technology, which is applied in the heating of coke ovens, coke ovens, auxiliary controllers with auxiliary heating devices, etc., can solve energy waste, affect the service life of coke ovens, and cannot measure temperature on time, advance or delay 1 minute wait

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

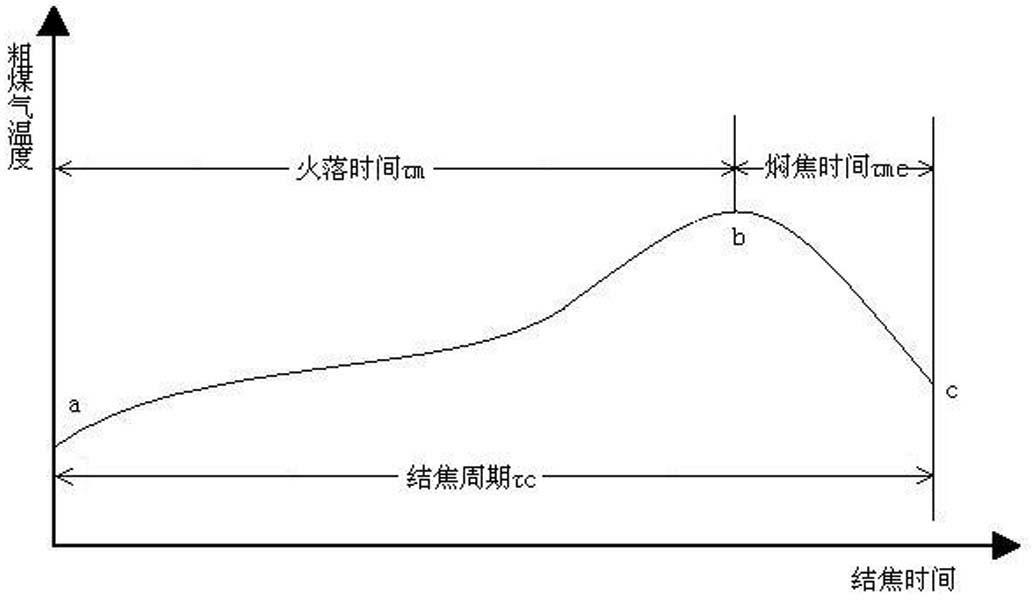

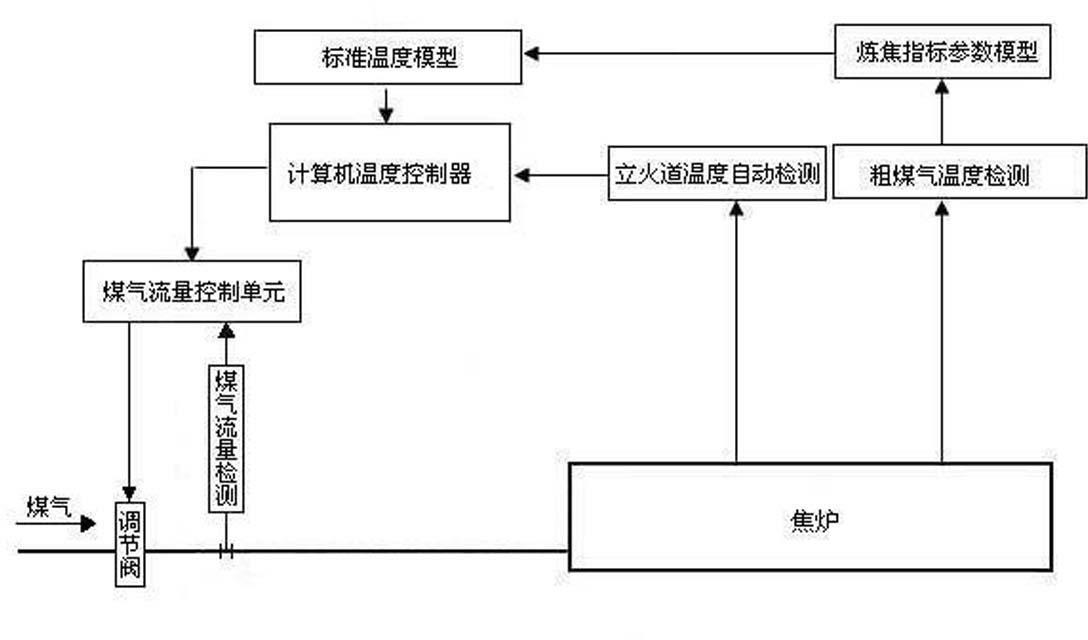

[0045] Take the JN60 coke oven as an example, with 50-hole carbonization chamber and 51-hole combustion chamber, and set the empirical coking index parameter of the coke oven as K 0 =1.4.

[0046] 1) In the first coking cycle, first set an empirical standard temperature T f =1200°C is the coking temperature for coking, and the coking index parameters K of 50 carbonization chambers of the coke oven are respectively detected 1 ~K 50 , and get the average coking index parameters of 50 carbonization chambers 1 (The test results are shown in Table 1, where τ c1 =24h), then correct the empirical standard temperature, and finally get the first standard temperature T of the coke oven s1 : T s1 = T f +10.24×τ c1 ×(1 / 1 -1 / K 0 ) = 1200+10.24×24×(1 / 1.53-1 / 1.4) = 1200-14.7=1185.3℃, which is the empirical standard temperature T f The standard temperature of the coke oven is 1185.3°C when it is lowered by 14.7°C.

[0047] Table 1 The coking index parameters of each carbonizat...

Embodiment 2

[0056] Embodiment 2 is similar to Embodiment 1, the difference is that the empirical standard temperature T set in the first coking cycle in Embodiment 2 f =1300℃, set the empirical coking index parameter of the coke oven as K 0 =1.2. When detecting the temperature of the vertical flue, two groups of combustion chambers are detected on the machine and the focal side, that is, 10 combustion chambers are detected on the machine and the focal side, and each group of combustion chambers is a compartment detection. The serial numbers of the tested combustion chambers are respectively:

[0057] Machine side (10, 12, 14, 16, 18), (43, 45, 47, 49, 51);

[0058]Focal side (11, 13, 15, 17, 19), (40, 42, 44, 46, 48).

[0059] All the other steps and methods are the same as in Example 1.

Embodiment 3

[0061] Embodiment 3 is similar to Embodiment 1, except that the empirical standard temperature T set in the first coking cycle in Embodiment 3 f =1250℃, set the empirical coking index parameter of the coke oven as K 0 =1.7. When detecting the temperature of the vertical flue, all the combustion chambers of the whole furnace are detected, that is, 51 combustion chambers are detected. All the other steps and methods are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com