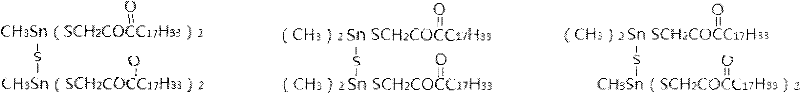

Preparation method of sulfur bridge-containing reverse ester thiol methyltin

A technology of retro ester mercaptan methyl tin and methyl tin trichloride, which is applied in the field of preparation of retro ester mercaptan methyl tin, can solve the problem that the bridging structure cannot be guaranteed, the reactant is easy to turn black, and the product quality is not good and other issues to achieve the best thermal stability, easy implementation, and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

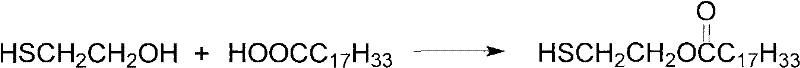

[0039] Preparation of mercaptoethanol oleate comprises the following steps:

[0040] a) Add 415g of oleic acid, 2g of alkyl titanate, 1g of hydroquinone and 120g of mercaptoethanol into a 1000ml first reaction vessel;

[0041] b) vacuumize and heat the first reaction vessel until the vacuum degree in the first reaction vessel reaches 200mmHg (absolute pressure) and the temperature reaches between 75-85°C, and then maintains the temperature between 75-85°C, and shall not exceed 85°C;

[0042] c) When a distillate is produced, the distillate is condensed and recovered; mercaptoethanol can be extracted from the distillate recovered by condensation for next use;

[0043] d) when the output speed of the distillate begins to decline, make the vacuum degree in the first reaction vessel reach 150mmHg (absolute pressure);

[0044] e) Control the degree of vacuum in the first reaction vessel to decrease stepwise according to 150mmHg, 100mmHg, and 30mmHg, and at the same time carefully o...

Embodiment 2

[0048] The preparation of methyl tin mercaptide in reverse ester comprises the following steps:

[0049] A) 680g mercaptoethanol oleate (the product obtained in Example 1) is added in the second reaction vessel of 2000ml;

[0050] B) the 440ml monomethyl tin trichloride aqueous solution that concentration is 53% and the 220ml sodium sulfide aqueous solution that concentration is 20% are added dropwise in the mercaptoethanol oleate in the second reaction vessel simultaneously, in the process of dropping , control the reaction temperature below 30°C, and react for 1.5 hours after the dropwise addition is completed;

[0051] C) dripping ammonia water with a concentration of 17%, until the pH value of the reactant in the second reaction vessel reaches between 6.5 and 7;

[0052] D) raising the temperature of the second reaction vessel to between 50 and 60°C, and keeping it warm for 1 hour;

[0053] E) make the second reaction vessel cool down, then add the water of 400ml in the ...

Embodiment 3

[0057] The preparation of methyl tin mercaptide in reverse ester comprises the following steps:

[0058] A) 680g mercaptoethanol oleate (the product obtained in Example 1) is added in the second reaction vessel of 2000ml;

[0059] B) the mixed aqueous solution of monomethyl tin trichloride and dimethyl tin dichloride of 500ml (wherein, the quality of monomethyl tin trichloride accounts for 40% of aqueous solution quality, dimethyl tin dichloride The mass accounts for 10% of the aqueous solution mass) and the 210ml sodium sulfide aqueous solution with a concentration of 20% is simultaneously added dropwise to the mercaptoethanol oleate in the second reaction vessel, and during the dropping process, the reaction temperature is controlled below 30°C; After the dropwise addition was completed, react for 1.5 hours;

[0060] C) dripping ammonia water with a concentration of 17%, until the pH value of the reactant in the second reaction vessel reaches between 6.5 and 7;

[0061] D)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com