Solid coated slow release selenium fertilizer and its preparation method

A technology of coated slow-release and selenium fertilizer, which is applied in the fields of fertilizer manufacturing, fertilizer and fertilizer manufacturing, can solve the problems of inconspicuous effective slow-release characteristics and high failure rate, achieve stable and sufficient supply for plant absorption and utilization, is conducive to maintenance, Realize the effect of fertilizer supply

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

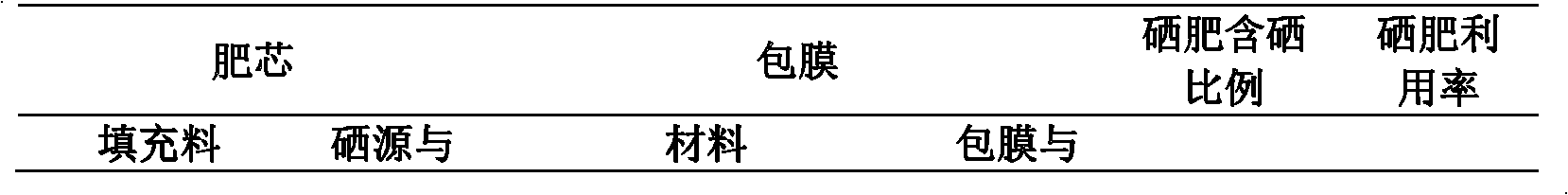

[0033] Sodium selenite is used as the selenium source material, different proportions of fillers and film materials are selected, the selenium source material and fillers are fully mixed, and then dry granulated to make a granular fertilizer core, and then different proportions of the fertilizer core are made by drum coating. The coating material is sprayed onto the surface of the granular fertilizer core to obtain a solid slow-release selenium fertilizer. In the field test, after a growth cycle of 4-6 months, the biomass and average selenium content of the growing crops were counted to evaluate the utilization rate of selenium in the solid slow-release selenium fertilizer. The specific experimental results are shown in Table 1:

[0034] Table 1 takes sodium selenite as the experimental result of selenium source

[0035]

[0036]

Embodiment 2

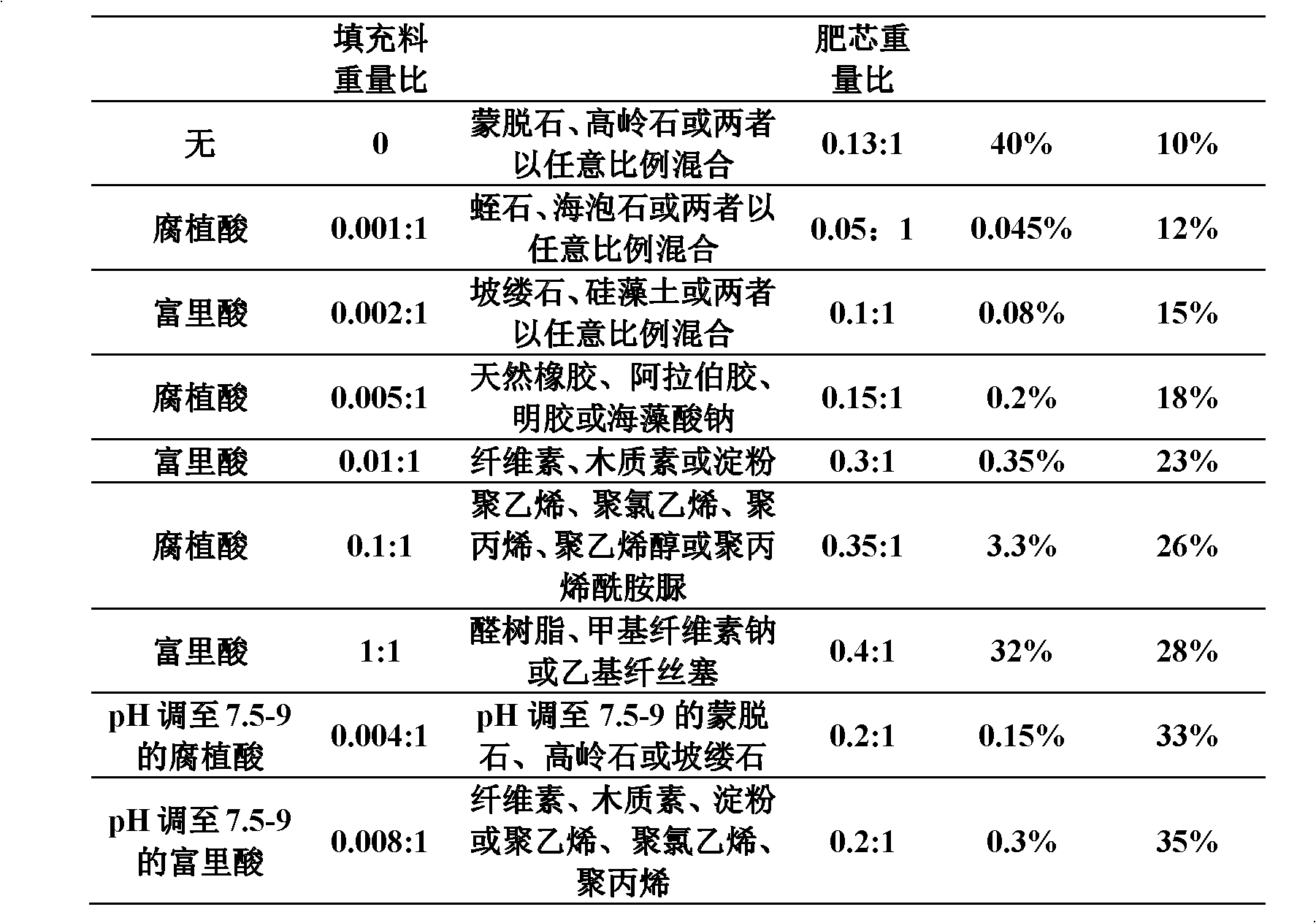

[0038] Sodium selenate is used as the selenium source material, different proportions of fillers and film materials are selected, the selenium source material and fillers are fully mixed, and dry granulation is carried out to make granular fertilizer cores, and then the different proportions of the packaged fertilizers are coated by the drum coating method. The membrane material is sprayed onto the surface of the granular fertilizer core to obtain a solid slow-release selenium fertilizer. In the field test, after a growth cycle of 4-6 months, the biomass and average selenium content of the growing crops were counted to evaluate the utilization rate of selenium in the solid slow-release selenium fertilizer. The specific experimental results are shown in Table 2:

[0039] Table 2 takes sodium selenate as the experimental result of selenium source

[0040]

[0041]

Embodiment 3

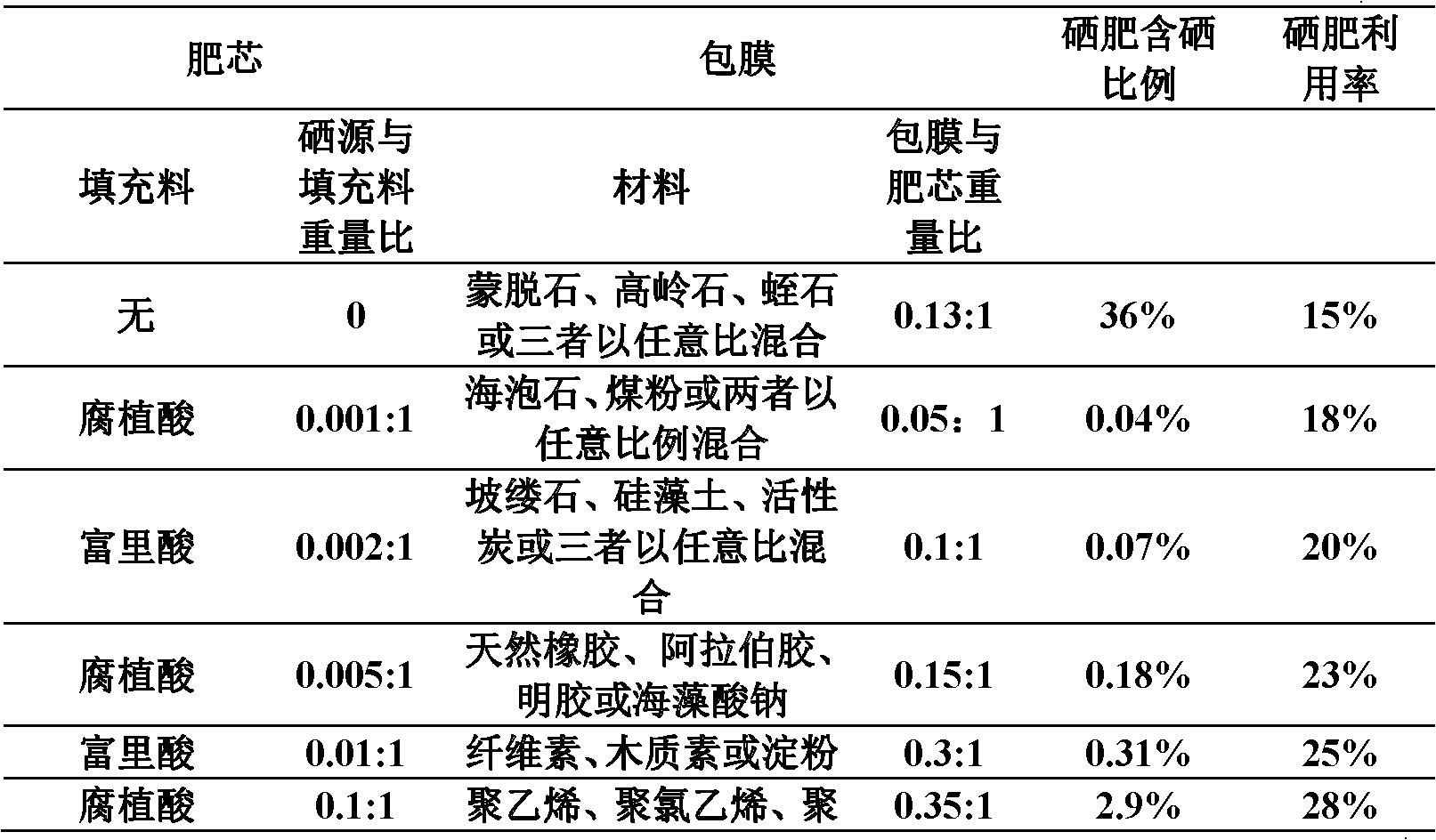

[0043] Select selenium-containing ore powder with a selenium content of more than 1000 μg / kg, and use ammonia water as the selenium source material after crushing, select different proportions of fillers and film materials, fully mix the selenium source material and fillers, and then carry out dry process The granules are made into granular fertilizer cores, and then different proportions of coating materials are sprayed onto the surface of the granular fertilizer cores by a drum coating method to obtain solid slow-release selenium fertilizers. In the field test, after a growth cycle of 4-6 months, the biomass and average selenium content of the growing crops were counted to evaluate the utilization rate of selenium in the solid slow-release selenium fertilizer. The specific experimental results are shown in Table 3:

[0044] Table 3 takes sodium selenate as the experimental result of selenium source

[0045]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com