Chemical foaming cement fireproofing heat-preservation structure and preparation method thereof

A technology of fire-proof heat preservation and chemical foaming, which is applied in the field of chemical foamed cement fire-proof heat preservation structure and its preparation, can solve the problems of poor heat preservation effect, easy hollowing, falling off, large equipment investment, etc., and achieves excellent heat preservation effect and condensation effect. Fast time and good air environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

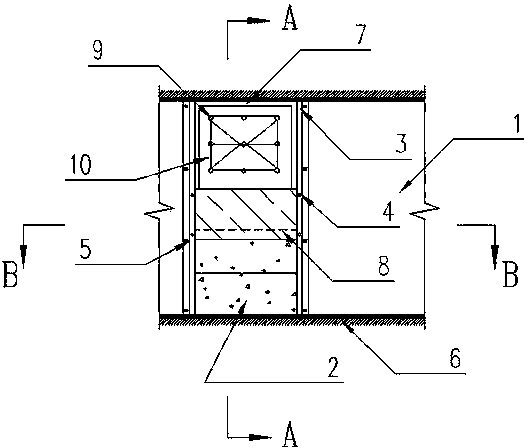

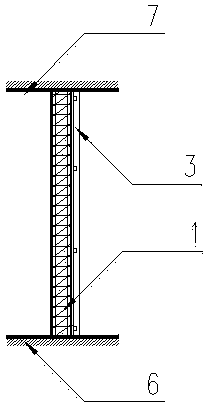

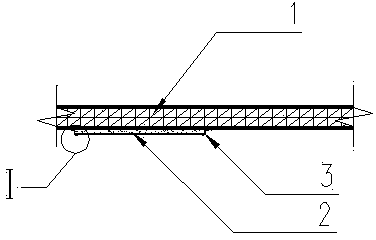

[0044] A chemically foamed cement fireproof and heat-insulating structure, the chemically foamed cement fireproof and heat-insulating structure is an insulation layer 2 formed by pouring a chemical foaming composition on the wall surface of a building wall 1, and the components of the chemical foaming composition The composition and weight ratio include: 150 parts by weight of sulphoaluminate cement (can be kilograms, the same below), fly ash (preferably grade 1 or grade 2, and the sieve with a fineness of 0.045mm square hole is not more than 20% fly ash) 55 parts by weight, 10 parts by weight of hydrogen peroxide with a concentration of 27.5% by weight, 1.1 parts by weight of vinyl acetate-ethylene copolymer emulsion, 2 parts by weight of water reducing agent, polypropylene short fiber (ie PP fiber , the length is preferably 5-15 mm), 0.5 parts by weight, 5 parts by weight of calcium stearate, and 32 parts by weight of water.

Embodiment 2

[0046] A chemically foamed cement fireproof and heat-insulating structure, the chemically foamed cement fireproof and heat-insulating structure is an insulation layer 2 formed by pouring a chemical foaming composition on the wall surface of a building wall 1, and the components of the chemical foaming composition The composition and weight ratio include: 120 parts by weight of sulfoaluminate cement (may be in kilograms, the same below), fly ash (preferably grade 1 or grade 2, and the sieve residue of a square hole sieve with a fineness of 0.045mm is not more than 20% fly ash) 50 parts by weight, 7.5 parts by weight of hydrogen peroxide with a concentration of 27.5% by weight, 0.8 parts by weight of vinyl acetate-ethylene copolymer emulsion, 0.5 parts by weight of water reducer, polypropylene short fiber (ie PP fiber , preferably 5-15mm in length), 0.3 parts by weight, 3 parts by weight of calcium stearate, and 28 parts by weight of water.

Embodiment 3

[0048] A chemically foamed cement fireproof and heat-insulating structure, the chemically foamed cement fireproof and heat-insulating structure is an insulation layer 2 formed by pouring a chemical foaming composition on the wall surface of a building wall 1, and the components of the chemical foaming composition The composition and weight ratio include: 180 parts by weight of sulfoaluminate cement (may be in kilograms, the same below), fly ash (preferably grade 1 or grade 2, and the sieve residue of a square hole sieve with a fineness of 0.045mm is not more than 20% fly ash) 60 parts by weight, 12 parts by weight of hydrogen peroxide with a concentration of 27.5% by weight, 0.8 to 1.3 parts by weight of vinyl acetate-ethylene copolymer emulsion, 4 parts by weight of water reducer, polypropylene staple fiber (ie 0.8 parts by weight of PP fibers (preferably 5-15 mm in length), 7 parts by weight of calcium stearate, and 36 parts by weight of water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com