Mould of glassware cover

A technology for glassware and lids, which is applied in glass forming, glass pressing, and glass manufacturing equipment. It can solve problems such as easy-to-scratch lines, complicated operations, and conflicts in moving directions, and achieve reduced labor intensity, simple and convenient operation, and The effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

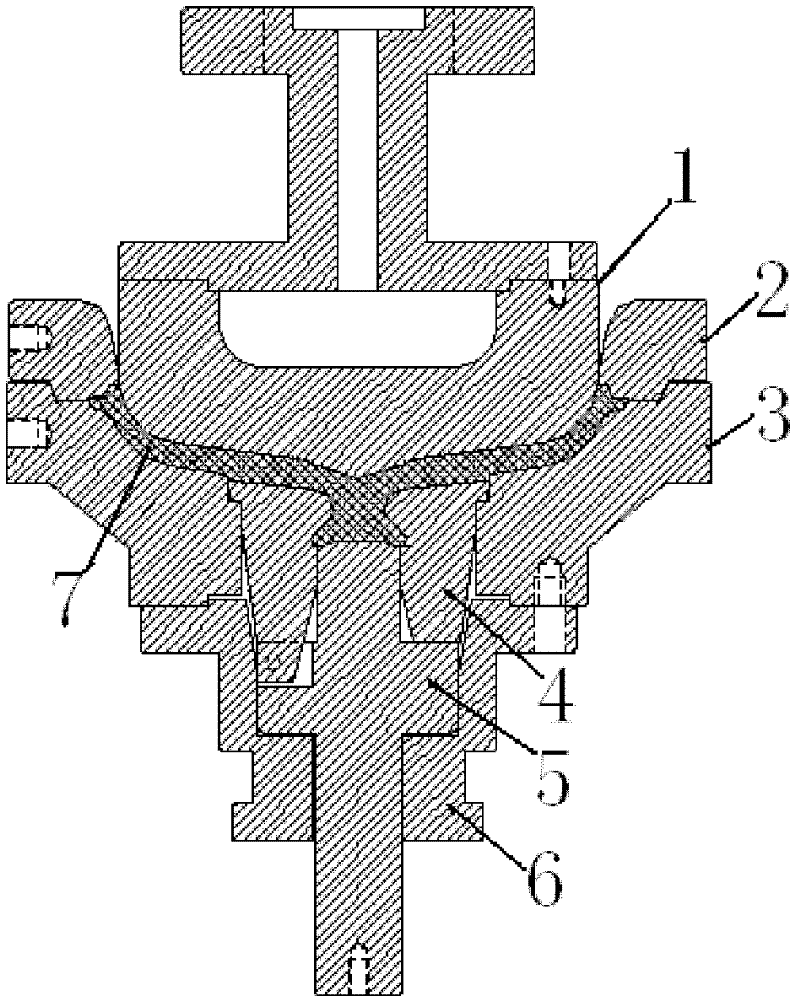

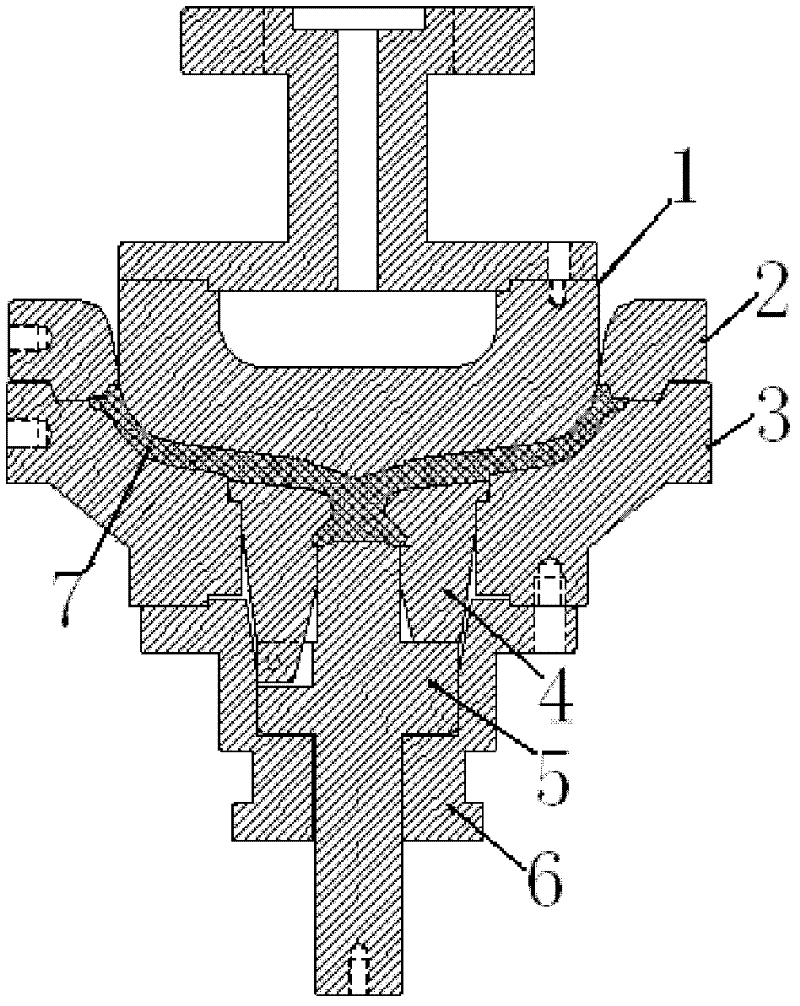

[0014] Such as figure 1 As shown, the glassware lid mold includes a punch 1, a cover plate 2, an upper mold 3, a lower mold 4, a lower mold ejector pin 5 and a base 6, a punch 1, a cover plate 2, an upper mold 3, a lower mold 4 and a lower mold Die ejector pin 5 constitutes the modeling space of glassware lid 7, and lower mold ejector pin 5 can be installed in the middle part of base 6 movably up and down, and upper mold 3 is installed on the outer edge of base 6.

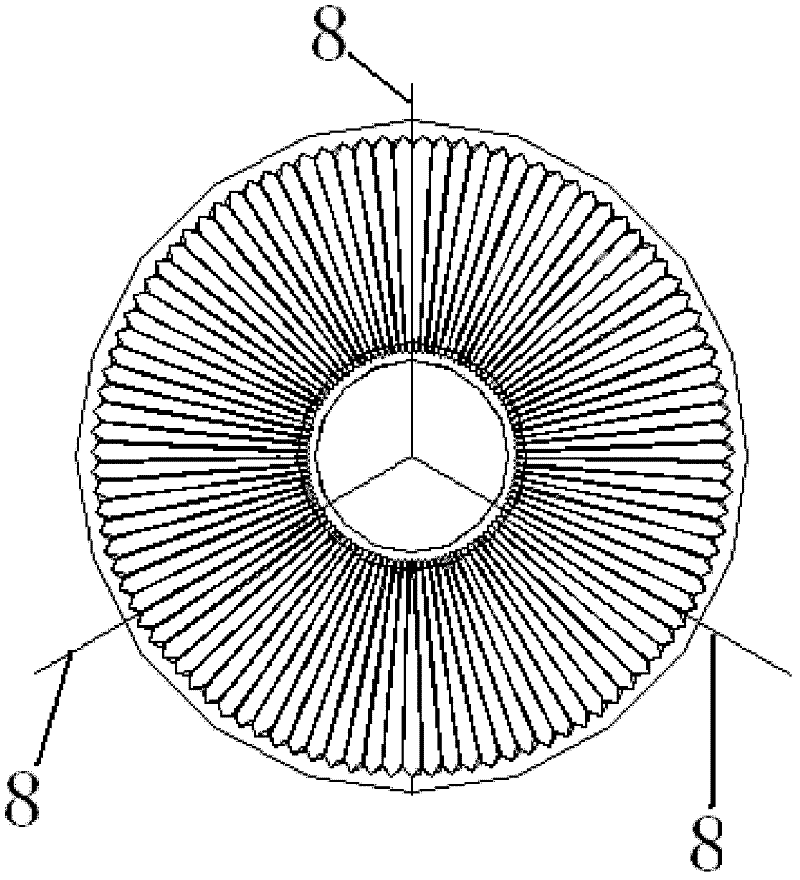

[0015] The lower mold 4 is a whole in the prior art, and lines or patterns are engraved in its inner cavity. After the whole process is completed, it is cut into three equal parts by wire cutting, such as figure 2 As shown, it divides into three equal parts along the center of symmetry, and the commissure line 8 makes it the equal line.

[0016] The lower mold 4 is located between the lower mold ejector pin 5 and the upper mold 3, and the equally divided parts are movably connected to the lower mold ejector pin 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com