Preparation method of stannic oxide/silica composite nano-particle

A composite nanoparticle and silicon dioxide technology, applied in the directions of silicon dioxide, tin oxide, silicon oxide, etc., can solve the problems of complex preparation process, harsh reaction conditions, introduction of impurities, etc., and achieve simple equipment process, good crystallinity, short cycle effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

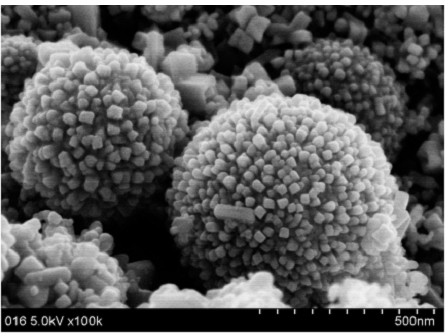

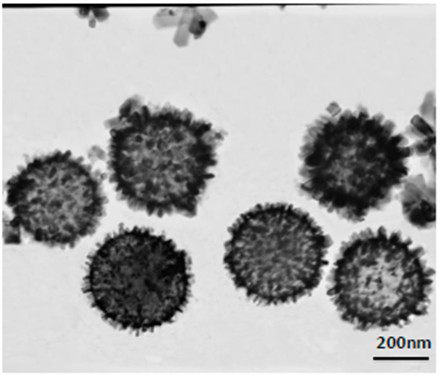

[0026] Dissolve crystalline tin tetrachloride / ethyl orthosilicate in a mixed solvent of water and ethanol to prepare a precursor solution; use a syringe pump to feed the precursor solution into a combustion reactor for hydrolysis reaction at a reaction temperature of 1500°C. Spherical silica particles are first formed in the flame, and then tin dioxide nucleates heterogeneously on its surface and grows in orientation, finally forming a nanocomposite structure of tin dioxide / silicon dioxide with a sea urchin-like structure.

[0027] Wherein: the volume ratio of water and ethanol is 1:5, the total concentration of tin source and silicon source in the mixed solvent is 0.5mol / L, and the molar ratio of tin source and silicon source is 1:1.

[0028] The feed rate of the precursor solution was 3ml / min, and the flow rate of oxygen was 0.3m 3 / h, the shear pressure is 0.15MPa.

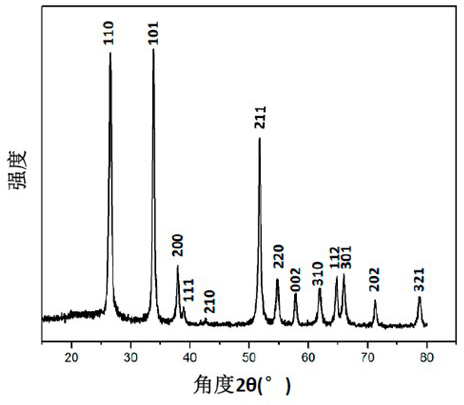

[0029] Such as Figure 1~4 As shown, the prepared tin dioxide / silicon dioxide composite nanoparticles have...

Embodiment 2

[0031] The mixed solvent of stannous chloride / dichlorodimethylsilane dissolved in water and ethanol will be prepared as a precursor solution; the precursor solution will be passed into the combustion reactor with a syringe pump for hydrolysis reaction, and the reaction temperature is 2000°C . Spherical silica particles are first formed in the flame, then tin dioxide nucleates heterogeneously on its surface and grows in orientation, finally forming a nanocomposite structure of tin dioxide / silicon dioxide with a sea urchin-like structure.

[0032] Wherein: the volume ratio of water and ethanol is 1:11, the total concentration of tin source and silicon source in the mixed solvent is 1mol / L, and the molar ratio of tin source and silicon source is 2:1.

[0033] The feed rate of the precursor solution was 4ml / min, and the flow rate of oxygen was 0.6m 3 / h, the shear pressure is 0.22MPa.

[0034] The prepared tin dioxide / silicon dioxide composite nanoparticles have a sea urchin-lik...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com