Follower rest for hydraulic automatically centering, automatically compensating and surface rolling

An automatic centering and automatic compensation technology, which is applied in the direction of large fixed members, metal processing machinery parts, metal processing equipment, etc., can solve the problem of unpublished exact surface roughness index and the inability to guarantee the accurate clamping force and clamping force of the workpiece. Inaccurate control and other problems, to achieve the effect of eliminating the phenomenon of over-loose or over-tight, simple structure, and loose tool requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

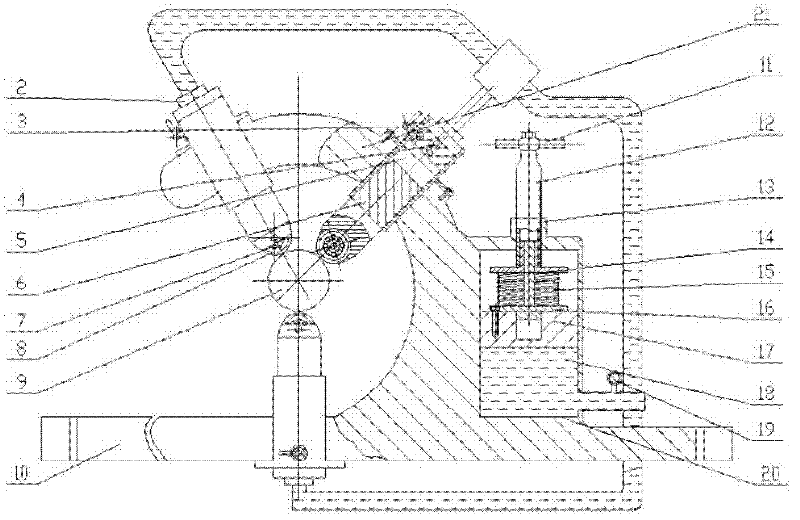

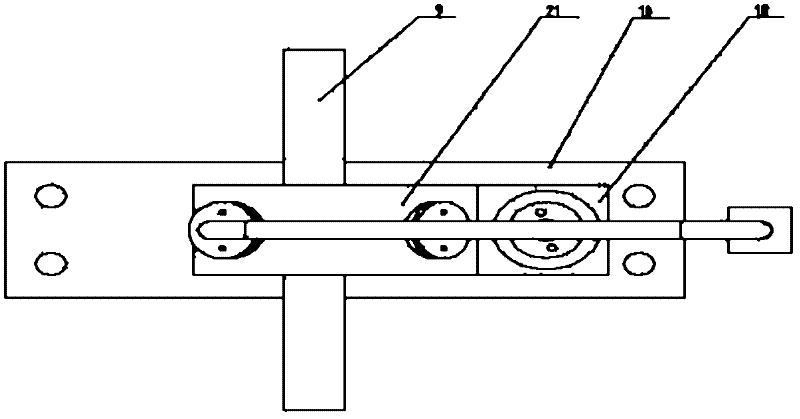

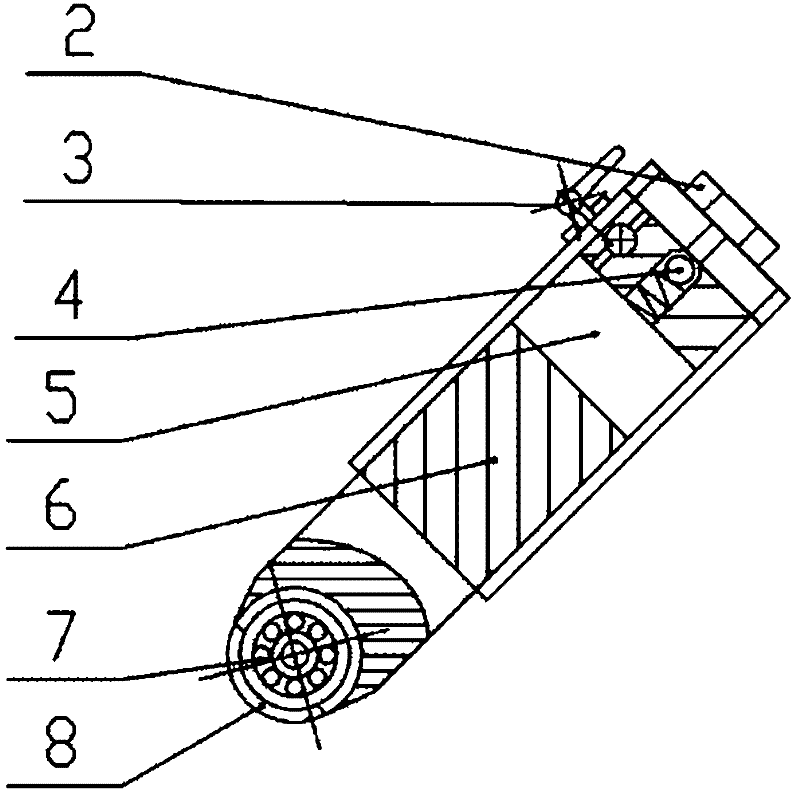

[0017] Example 1 as figure 1 As shown, a hydraulic automatic centering, automatic compensation and surface rolling heel tool holder includes 3 heel claw units, a hydraulic unit and a frame unit with the same structure; the frame unit includes a base plate 10, a large hydraulic cylinder Seat 20 and arc-shaped cantilever 21; large hydraulic cylinder seat 20 and arc-shaped cantilever 21 are cast on the base plate 10 by means of integral casting, and arc-shaped cantilever 21 is above one side of large hydraulic cylinder seat 20; 20 is processed into a large hydraulic cylinder 18; the bottom plate 10 is connected and fixed with the small supporting plate of the machine tool guide rail with bolts;

[0018] The axes of the three heel claw units are located in the same plane, and their extension lines intersect at one point. The heel claw unit installed on the bottom plate 10 is placed vertically, and the other two heel claw units are placed on the arc cantilever 21 In the hole, thre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com