Rolling mill guide mechanism

A technology of rolling mill and guiding device, applied in the direction of guiding/positioning/aligning device, etc., can solve the problems of unsatisfactory material rolling effect, inability to solve the problems such as rolling material running, increased raw material consumption, etc., so as to shorten the product delivery time, reduce rolling The effect of ideal control and profit maximization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

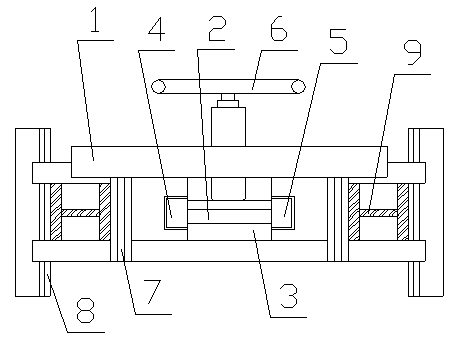

[0009] Embodiment 1: with reference to attached figure 1 , a rolling mill guide mechanism, which includes a frame 1, upper and lower clamping plates 2 and 3, left and right guides 4 and 5, the upper and lower clamping plates 2 and 3 are arranged on the frame 1 Between the upper and lower beams of the frame, the left and right guides 4 and 5 are installed on both sides of the upper and lower clamping plates 2 and 3, and the upper and lower guide adjustment devices 6 are installed on the upper beam of the frame 1, and the upper and lower guides are adjusted The adjusting rod at the bottom of the device 6 passes through the upper crossbeam and is connected with the upper clamping plate 2, and the upper and lower clamping plates 2 and 3 are connected with the left and right guides 4 and 5 to be provided with a locking plate. Both ends of the upper and lower beams are provided with openings for inserting plates, which are used to install quick inserting plates 7. Positioning guide ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com