Concentrating device and concentrating method of acarbose destaining solution

A technology of acarbose and decolorization solution, which is applied in the concentration equipment and concentration field of acarbose decolorization solution, which can solve the problems of low efficiency, time-consuming and energy-consuming, etc., so as to increase the processing capacity, speed up speed and efficiency, and speed up production The effect of the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

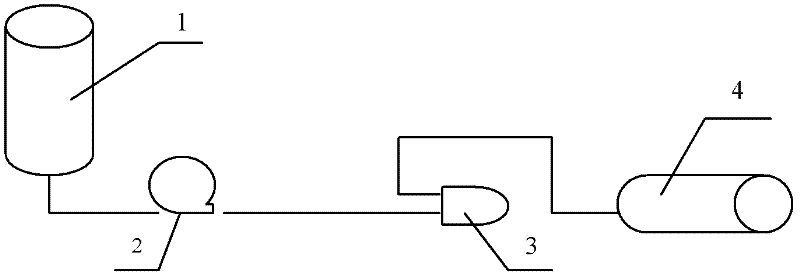

Embodiment 1

[0078] Output about 7000L of acarbose decolorization solution from the material tank, pressurize it to 0.40MPa through the pre-pressurization pump, and then input it to the high-pressure plunger pump through the stainless steel pipeline; adjust the plunger pump so that the pressure of the decolorization solution reaches 4.0MPa, with a flow rate of 5.5 tons / hour, it is input into a disc membrane (the molecular weight cut-off of the membrane is 150, and the material is polyamide) for concentration. The water in the decolorization solution enters the permeate collector through the membrane of the disc membrane and leaks out from the permeate outlet, while the acarbose that cannot pass through the membrane of the disc membrane flows into another storage tank , forming a concentrate. The concentration was completed in about 6 hours, and about 850 L of the concentrated solution in the form of a clear and transparent liquid was obtained, and the tested titer was about 260,000 μg / mL; ...

Embodiment 2

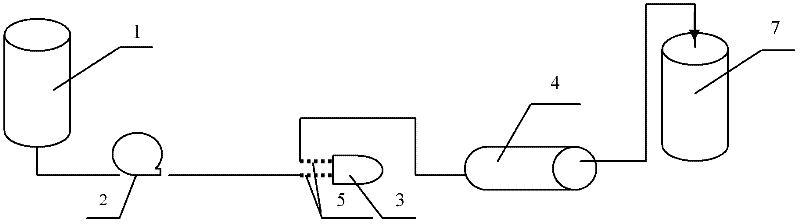

[0080] Output about 7000L of acarbose decolorization liquid from the material tank, pressurize it to 0.50MPa through the pre-pressurization pump, and then input it to the high-pressure plunger pump through stainless steel pipes and flexible pipes; adjust the plunger pump to make the decolorization The pressure of the liquid reaches 7.0MPa, and it is fed into the disc membrane (the molecular weight cut-off of the membrane is 380 and the material is polyamide) through flexible pipes and stainless steel pipes at a flow rate of 5.0 tons / hour for concentration. The water in the decolorization solution enters the permeate collector through the membrane of the disc membrane and leaks out from the permeate outlet, while the acarbose that cannot pass through the membrane of the disc membrane flows into another storage tank , forming a concentrate. Concentration was completed in about 7 hours, and about 700 L of the concentrated solution in the form of a clear and transparent liquid was...

Embodiment 3

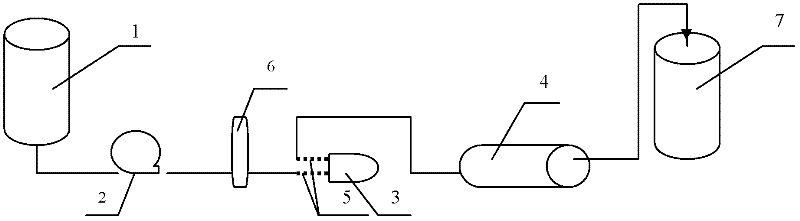

[0082] About 7000L of acarbose decolorization liquid is output from the material tank, pressurized to 0.45MPa by the pre-pressurization pump, and then input to the filter device with a pore size of 15μm, and the filtrate is input to the high-pressure plunger pump through stainless steel pipes and flexible pipes ; Regulate the plunger pump so that the pressure of the decolorizing solution reaches 5.0MPa, and enter the disc membrane (wherein the molecular weight cut-off of the diaphragm is 200, and the material is polyethersulfone ) to concentrate. The water in the decolorization solution enters the permeate collector through the membrane of the disc membrane and leaks out from the permeate outlet, while the acarbose that cannot pass through the membrane of the disc membrane flows into another storage tank , forming a concentrate. Concentration was completed in about 6.5 hours, and about 800 L of the concentrated solution in the form of a clear and transparent liquid was obtain...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com