Integrated built-in motor for electric-bicycle motor wheel disc

A technology for electric bicycles and mid-mounted motors, applied in the direction of electromechanical devices, electric components, electrical components, etc., can solve the problems of low quality of the drive control system, incomplete design and manufacturing technology, and poor climbing ability of low-speed hub motors. Achieve good climbing and riding performance, light weight and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

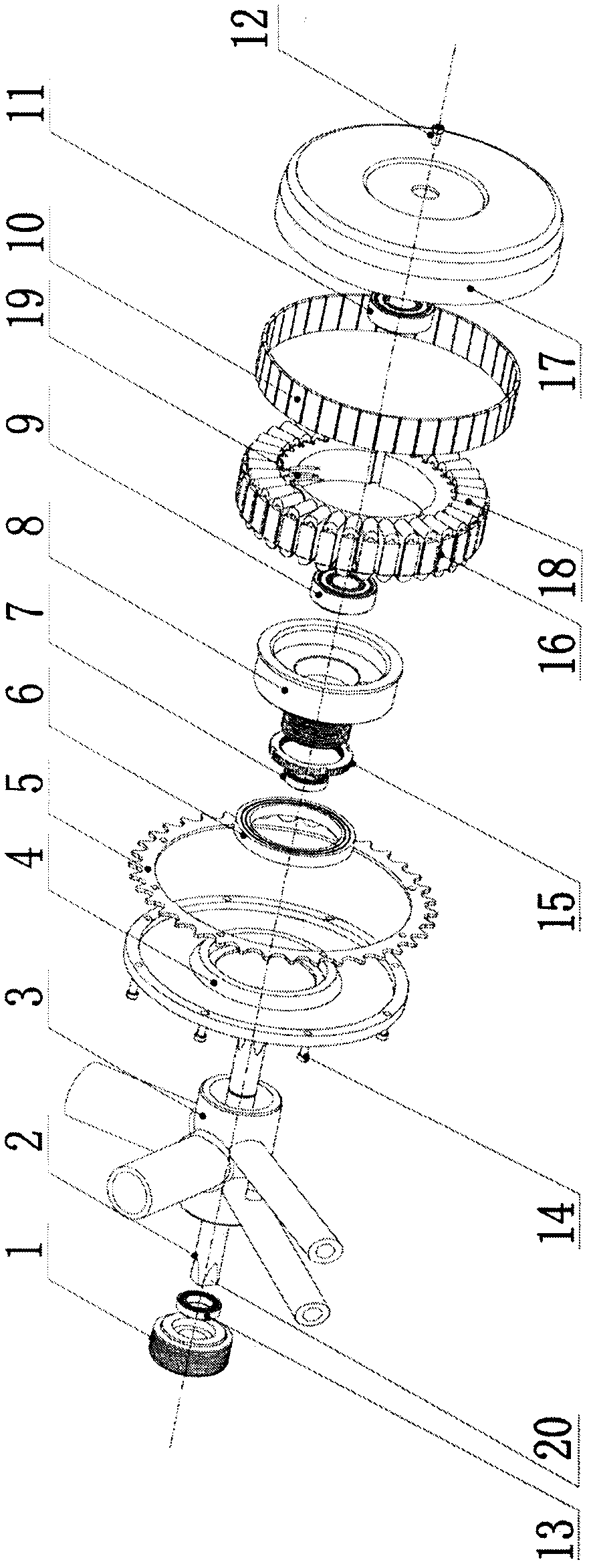

[0026] Refer to attached Figure 1~4 , The electric bicycle motor wheel disc integrated central motor includes left silk bowl 1, motor center shaft 2, motor inner end cover 4, sprocket (sprocket) 5, bearing one 6, bearing two 7, stator inner core 8, bearing Three 9, magnetic steel 10, one-way clutch 11, bearing four 13, right lock nut 15, stator silicon steel sheet (stator punching sheet) 16 and motor outer end cover 17.

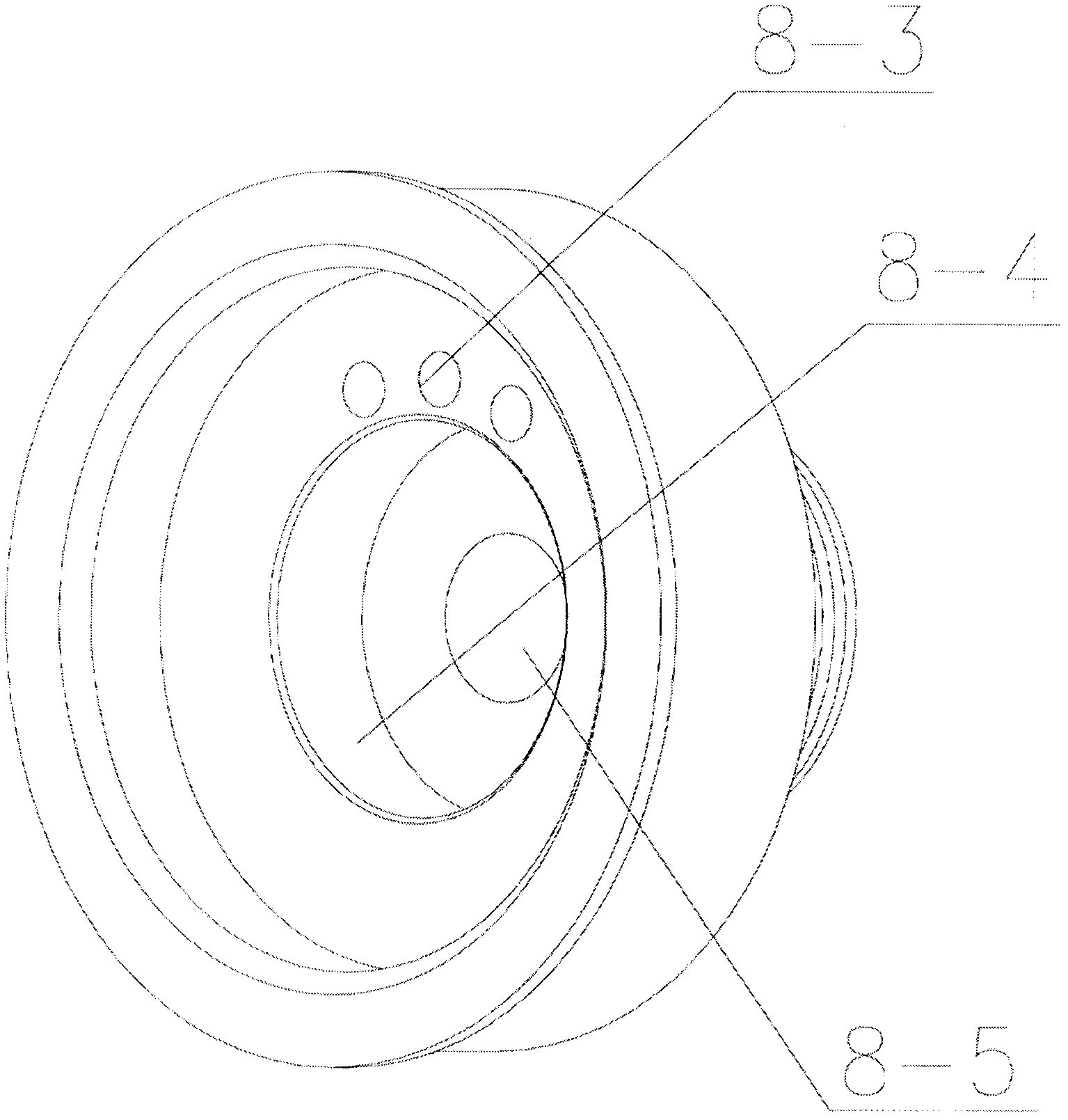

[0027] The left end of the stator inner core 8 is provided with a second bearing installation hole 8-1, the left end of the stator inner core 8 is provided with an external thread 8-2, the right end of the stator inner core 8 is provided with a bearing third installation hole 8-4, and the stator inner core 8 is provided with The through hole 8-5 is used to install the central shaft 2 of the motor, the second bearing 7 is installed in the second bearing installation hole 8-1 at the left end of the stator inner core 8, the first bearing 6 is installed on the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com