Passive-phase-locked fiber ring laser

A fiber laser and phase locking technology, applied in lasers, laser parts, phonon exciters, etc., can solve the problems of difficult production of fiber couplers, complex structure, difficult to effectively improve the output power, etc., to achieve simple structure, light beam The effect of good quality and high output power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0033] Implementation Mode 1 (N)

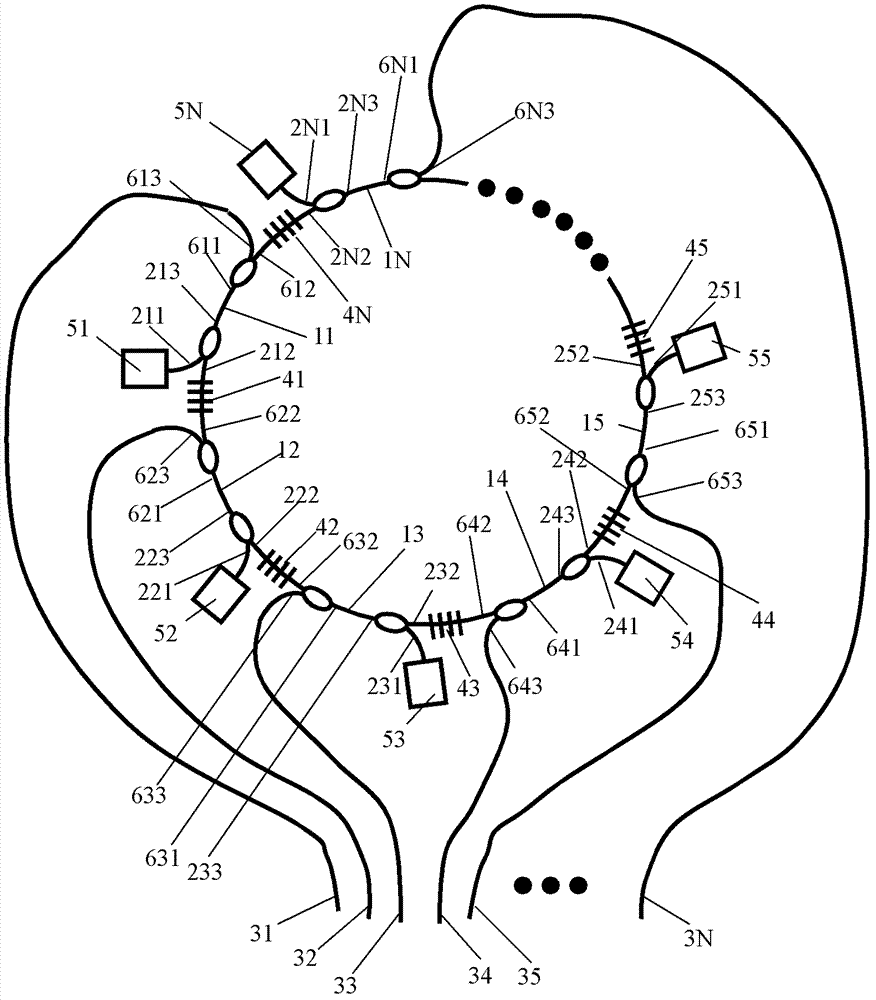

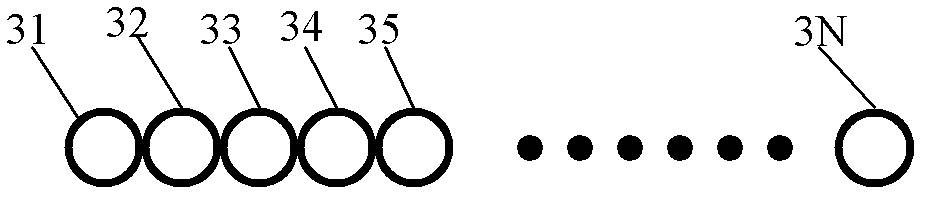

[0034] Ring-cavity passively phase-locked fiber lasers such as figure 1 , 2 As shown, the laser includes first to Nth active single-mode optical fibers 11, 12, 13, 14, 15, ..., 1N, first to Nth wavelength division multiplexers, first to Nth single-mode optical fibers 31, 32, 33, 34, 35, ..., 3N, first to Nth fiber gratings 41, 42, 43, 44, 45, ..., 4N, first to Nth pumping sources 51, 52, 53 , 54, 55, ..., 5N and the first to Nth couplers.

[0035] The first port 211 of the first wavelength division multiplexer is connected with the first pump source 51, the second port 212 of the first wavelength division multiplexer is connected with an end of the first fiber grating 41, the first wavelength division multiplexer The third port 213 of the first active single-mode fiber 11 is connected to one end, the other end of the first active single-mode fiber 11 is connected to the first port 611 of the first coupler, and the second port 612 of the fi...

Embodiment approach 2

[0044] Embodiment 2 (N=3)

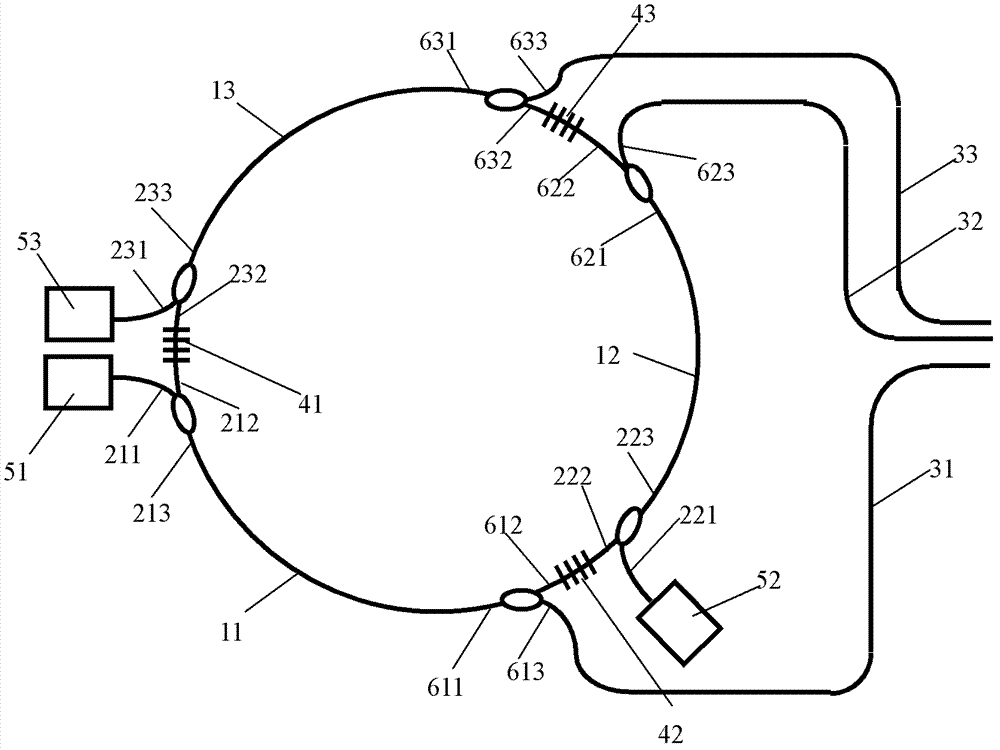

[0045] Ring-cavity passively phase-locked fiber lasers such as image 3 , 4 As shown, the laser includes first to third active single-mode fibers 11, 12, 13, first to third wavelength division multiplexers, first to third single-mode fibers 31, 32, 33, first to third Third fiber gratings 41, 42, 43, first to third pumping sources 51, 52, 53 and first to third couplers.

[0046] The first port 211 of the first wavelength division multiplexer is connected with the first pump source 51, the second port 212 of the first wavelength division multiplexer is connected with an end of the first fiber grating 41, the first wavelength division multiplexer The third port 213 of the first active single-mode fiber 11 is connected to one end, the other end of the first active single-mode fiber 11 is connected to the first port 611 of the first coupler, and the second port 612 of the first coupler It is connected to one end of the second fiber grating 42 , and th...

Embodiment approach 3

[0051] Embodiment 3 (N=4)

[0052] Ring-cavity passively phase-locked fiber lasers such as Figure 5 , 6 As shown, the laser includes first to fourth active single-mode fibers 11, 12, 13, 14, first to fourth wavelength division multiplexers, first to fourth single-mode fibers 31, 32, 33, 34 , first to fourth fiber gratings 41, 42, 43, 44, first to fourth pumping sources 51, 52, 53, 54 and first to fourth couplers.

[0053] The first port 211 of the first wavelength division multiplexer is connected with the first pump source 51, the second port 212 of the first wavelength division multiplexer is connected with an end of the first fiber grating 41, the first wavelength division multiplexer The third port 213 of the first active single-mode fiber 11 is connected to one end, the other end of the first active single-mode fiber 11 is connected to the first port 611 of the first coupler, and the second port 612 of the first coupler It is connected to one end of the fourth fiber g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com