Vertical inverted trapezoidal energy-saving oven with double working area

An inverted trapezoidal, working area technology, used in drying, dryers, progressive dryers, etc., can solve the problems of low utilization rate of heat energy and low drying efficiency of bottle caps, and achieve safe use and improve heat energy. Utilization rate, the effect of avoiding pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order for those skilled in the art to better understand the technical solutions provided by the present invention, the following will be described in conjunction with specific embodiments.

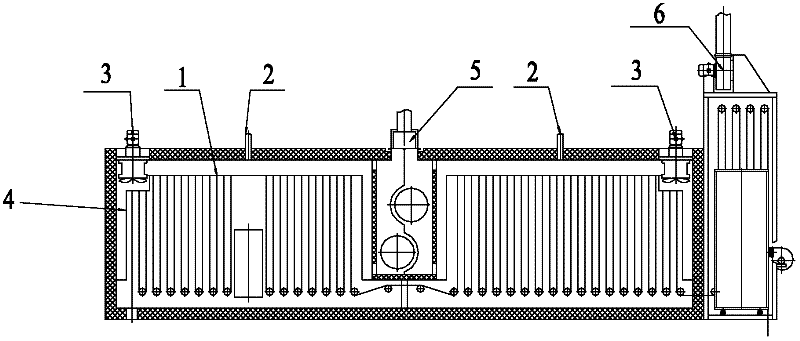

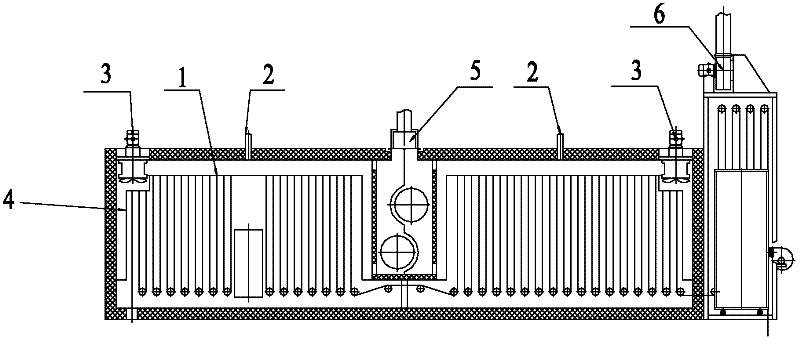

[0017] See figure 1 , which is a schematic structural view of a vertical inverted trapezoidal double-working area energy-saving oven of the present invention.

[0018] The vertical inverted trapezoidal double work area energy-saving oven provided by the present invention includes a burner, a hot air circulation duct, an oven cavity 4, a motor and a hanging cover chain 1, the hanging cover chain 1 is arranged in the oven cavity 4, and the chain 1 is set There is a cap hanging rod for hanging bottle caps, and the cap hanging chain is driven by a motor; the hot air circulation air duct is isolated from the oven cavity 4, and the hot air circulation air duct is connected with the burner, and the cap hanging chain 1 is in two rows.

[0019] The vertical inverted trapezoidal double wo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com