Connecting piece, back board and liquid crystal display device

A technology for a liquid crystal display device and a connector, which is applied to lighting devices, fixed lighting devices, lighting auxiliary devices, etc., can solve problems such as difficulty in PCB boards and decreased strength of backplanes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings and preferred embodiments.

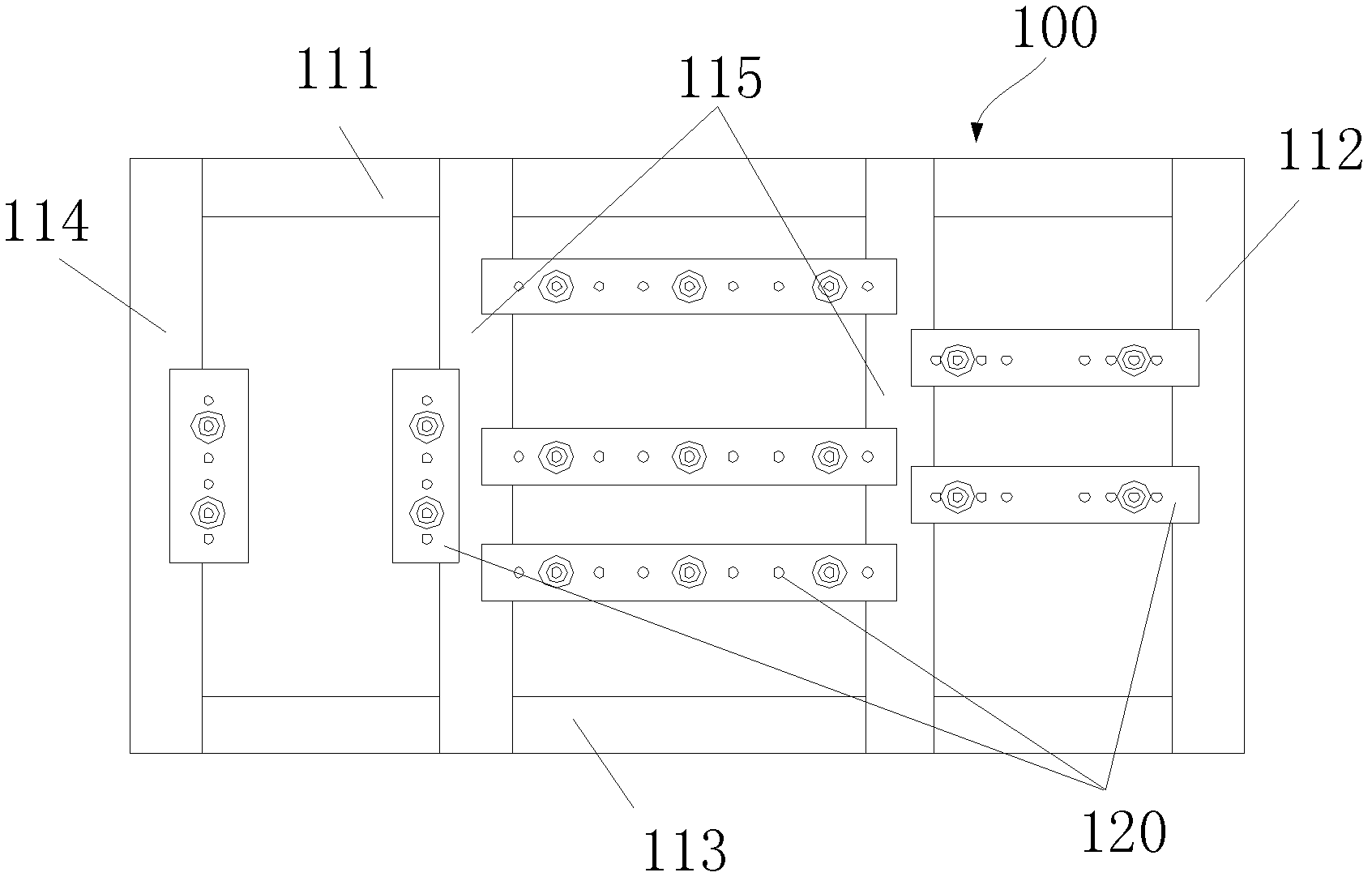

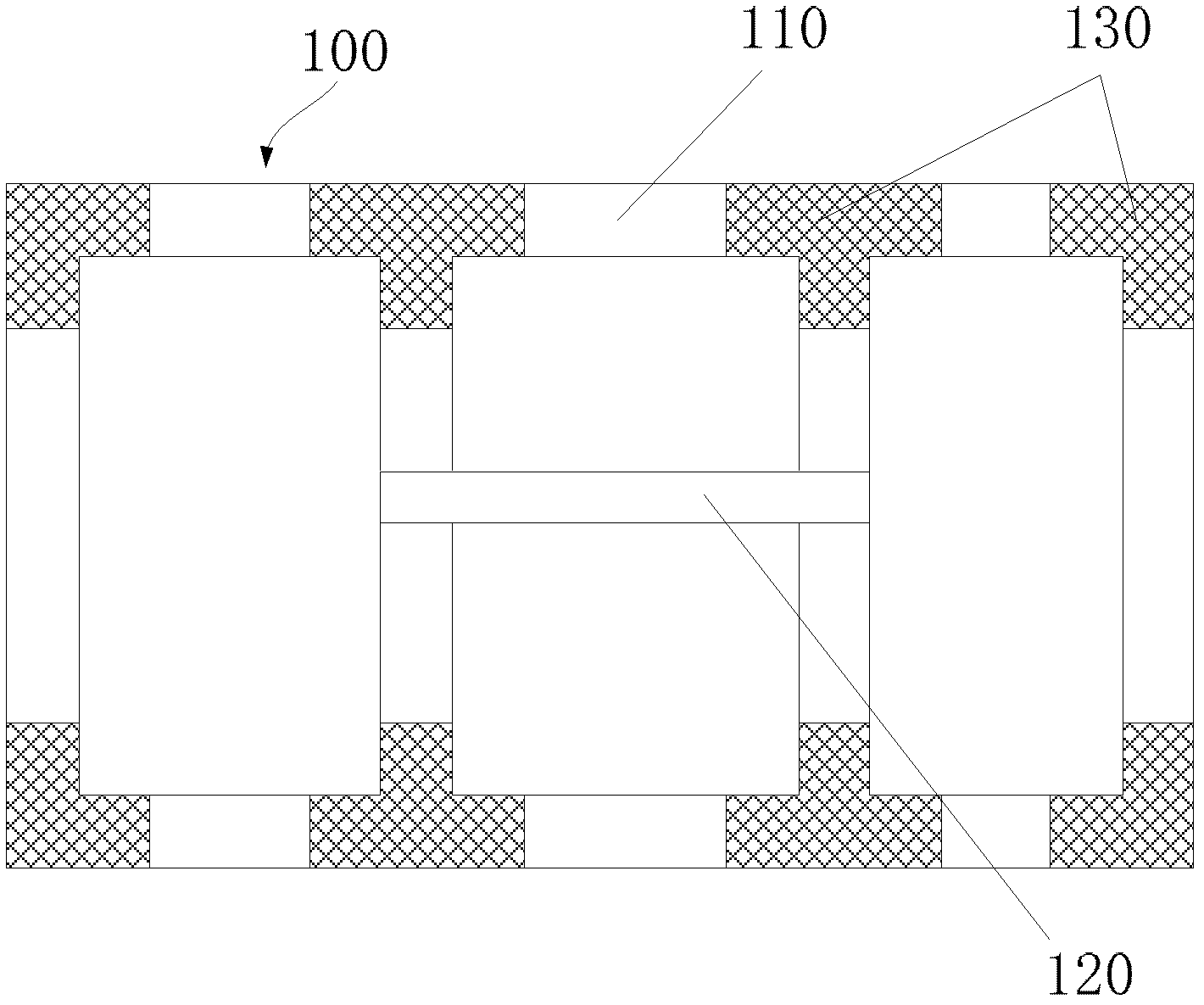

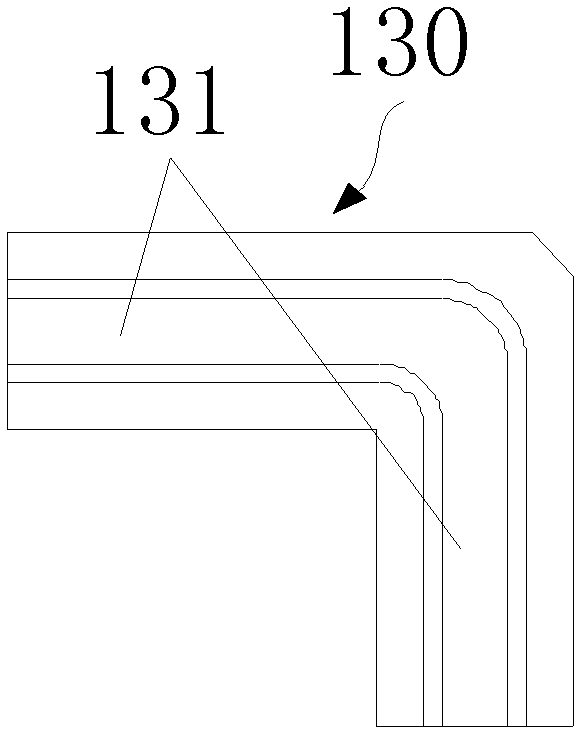

[0032] A liquid crystal display device includes a liquid crystal panel and a backlight module, and a back plate is arranged at the bottom of the backlight module. The backplane includes a frame 100 composed of a plurality of brackets 110 , and a plurality of bridges 120 are arranged on the frame 100 . Such as figure 1 As shown, the bracket 110 includes an upper bracket 111, a lower bracket 113, a left bracket 114, and a right bracket 112 connected end to end to form the large frame 100 of the entire backplane. The large frame 100 is also provided with two middle brackets 115, the middle Two ends of the bracket 115 are respectively fixed on the upper and lower brackets 110 . A plurality of bridging bridges 120 are provided on each bracket 110 and between two brackets 110 , and the bridging bridges 120 can be used to fix the PCB board and othe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com