Elastic damper, material distribution arm support and concrete material distribution equipment

An elastic damper, elastic damping technology, applied in mechanical equipment, springs/shock absorbers, shock absorbers, etc., can solve problems such as loss of use function, elbow wear, wear through, concrete segregation, etc., to prevent segregation, Extended service life, avoiding high-speed shock and wear effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

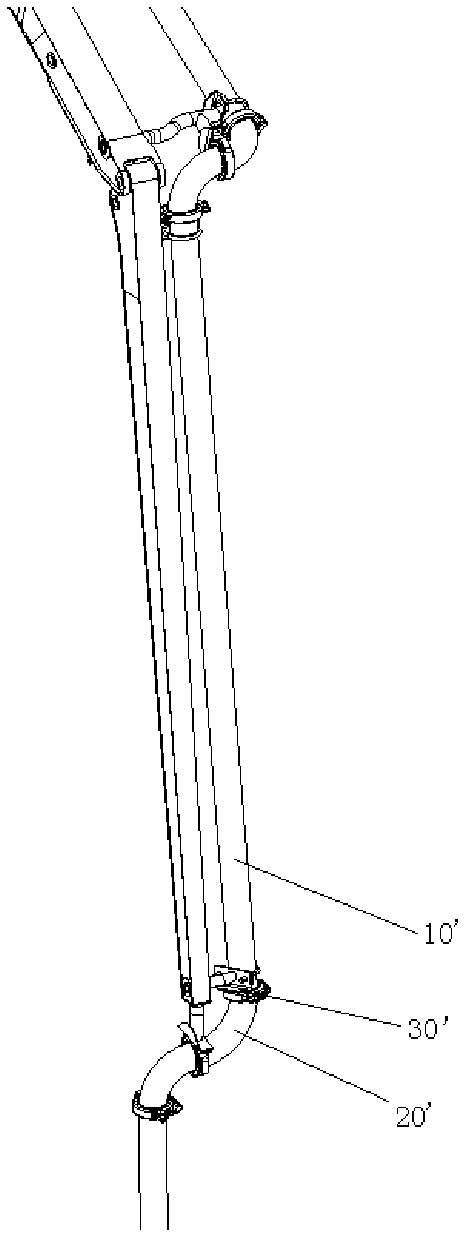

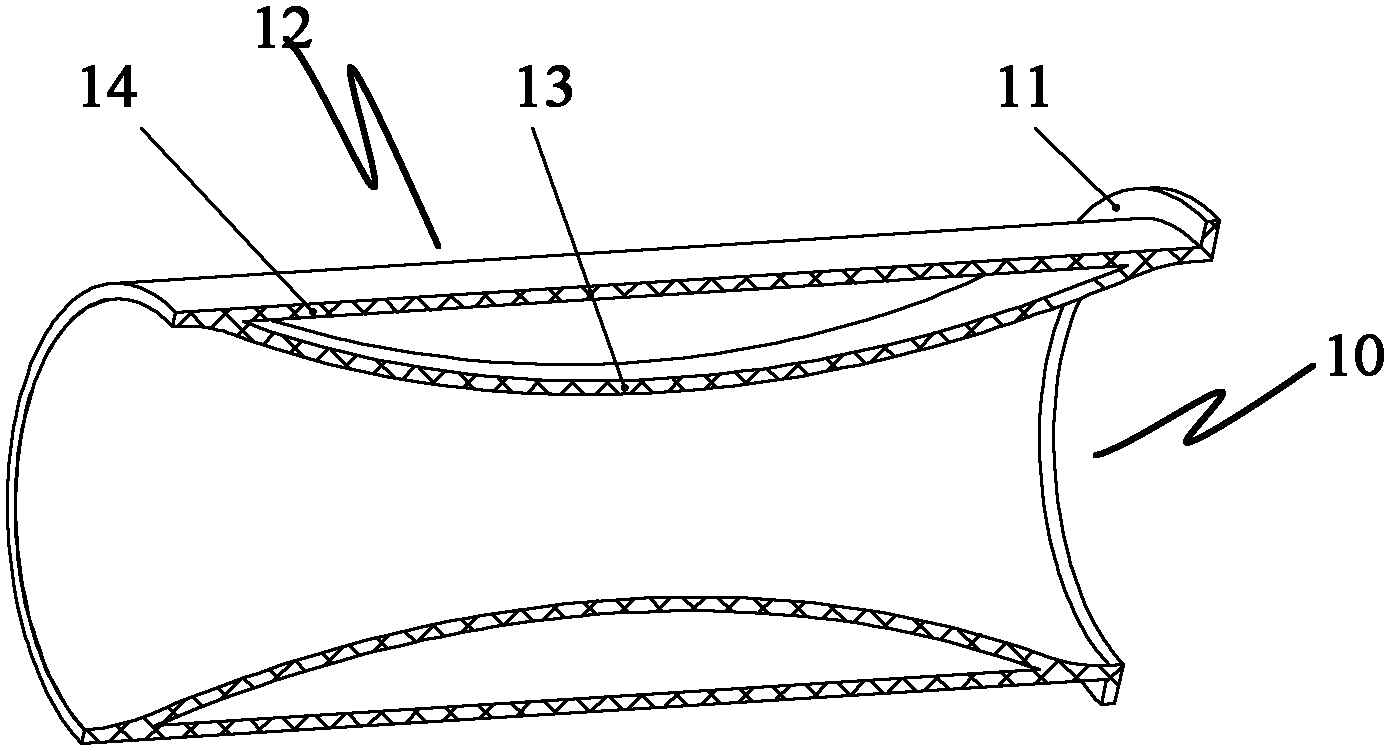

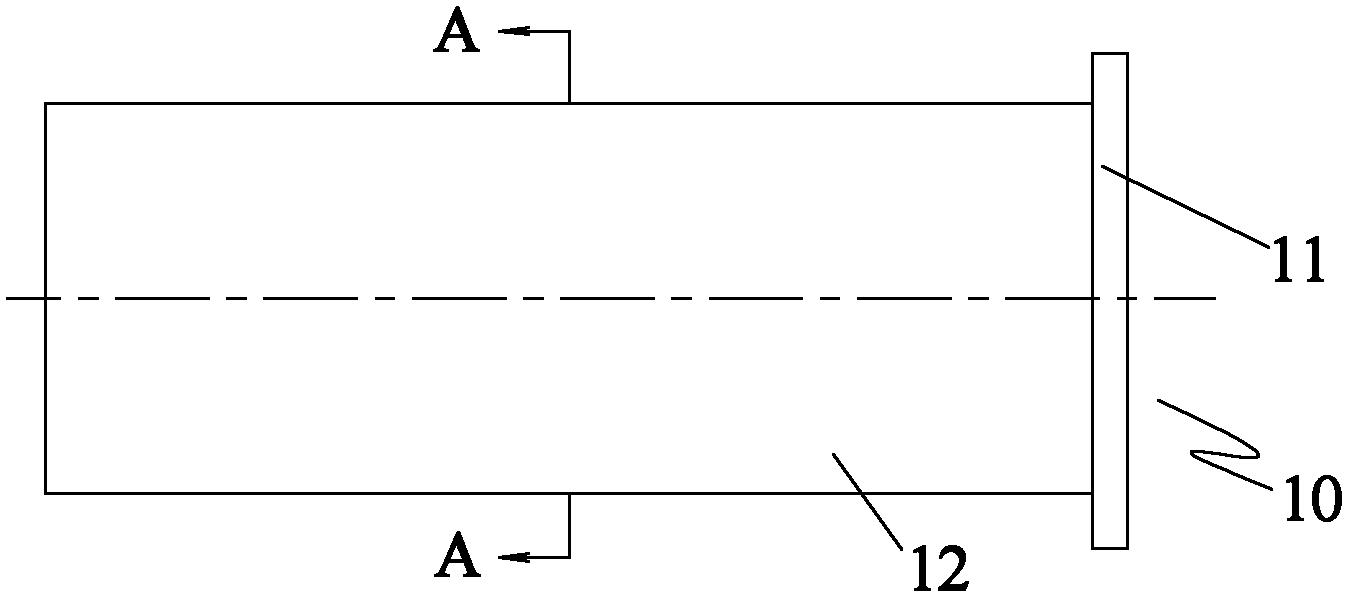

[0028] Hereinafter, the present invention will be described in detail with reference to the drawings and examples. It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other.

[0029] The arrows in the figure point to the concrete conveying direction.

[0030] Such as figure 2 , image 3 with Figure 4 As shown, according to the first embodiment of the present invention, the elastic damper 10 includes a positioning notch 11 and an elastic damping tube 12 disposed on one side of the positioning notch 11 . The positioning notch 11 is a flange structure arranged at the mouth of the elastic damping tube 12 . The elastic damping tube 12 includes an elastic wall 13 protruding toward the central axis of the elastic damping tube 12 and an outer connecting wall 14 disposed on the outer periphery of the elastic wall 13 . The elastic wall 13 is fixedly connected to the positioni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com