Method for building ultrathin light-load heat preservation type solar greenhouse back slope

A technology for a solar greenhouse and a construction method, applied in the field of solar greenhouses, can solve the problems of easy rupture of the waterproof layer, increased construction cost, complicated construction, etc., and achieve the effects of being less prone to mildew and deterioration, reducing manufacturing costs, and reducing cross-flow heat release.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

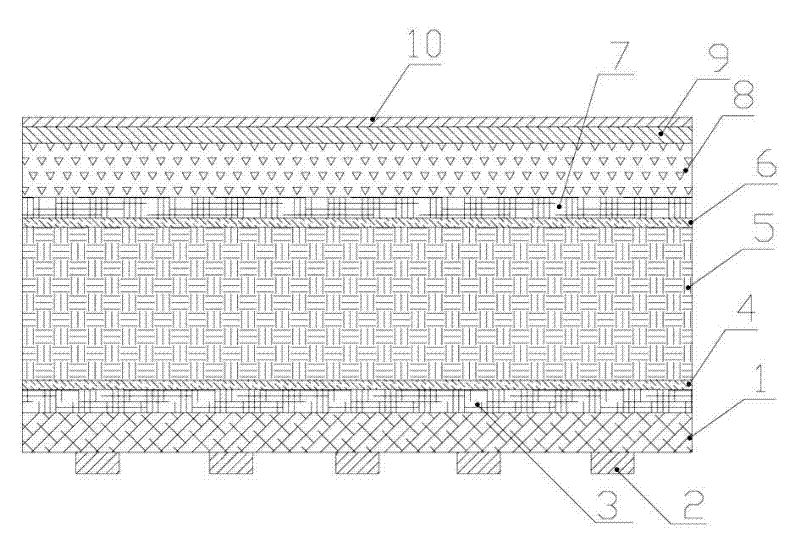

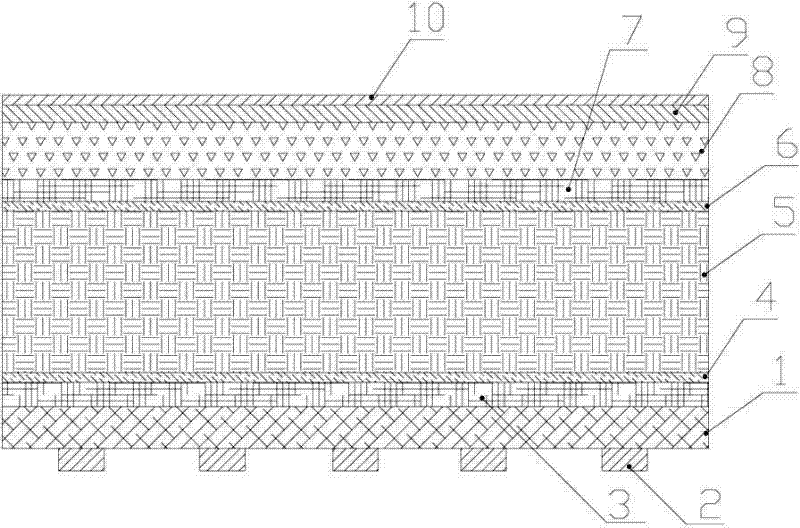

[0023] Such as figure 1 As shown, the construction method of the ultra-thin light-load heat preservation type solar greenhouse back slope of the present invention is carried out according to the following steps:

[0024] The first step, the construction of the load layer: use 4-6 strip steel plates 2 along the east-west direction to connect with the back slope frame of the greenhouse as the back slope support, and cover and fix a layer of PC board 1 on it;

[0025] The second step, the construction of the insulation layer: the first linoleum layer 3, the first plastic film layer 4, the grass thatch layer 5, the second plastic film layer 6, the second Linoleum layer 7;

[0026] The third step, the construction of the waterproof layer: laying the concrete layer 8, the styrene-butadiene-styrene rubber modified asphalt waterproof layer 9, and the aluminum foil layer 10 sequentially on the upper surface of the second felt layer 7 from bottom to top.

[0027] The thickness of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com