Hollow stiffness-core slurry-solidified discrete material pile and construction method thereof

A technology for piles and grouting of bulk materials, which is applied to sheet pile walls, infrastructure engineering, construction, etc., can solve the problems of large differences in stiffness of bulk materials, difficulty in exerting the bearing capacity of materials, and inability to perform grouting reinforcement, etc. To achieve the effect of clear construction process, simple and efficient construction process and good pile forming effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

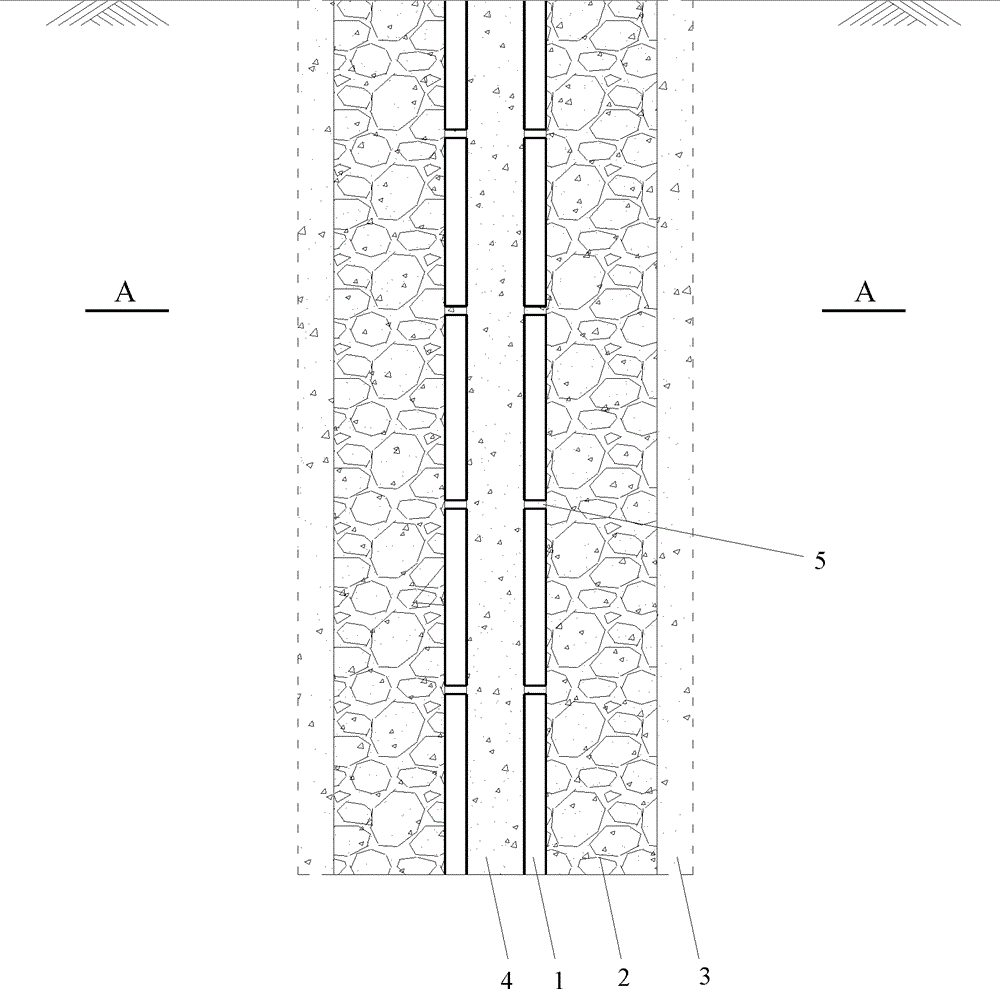

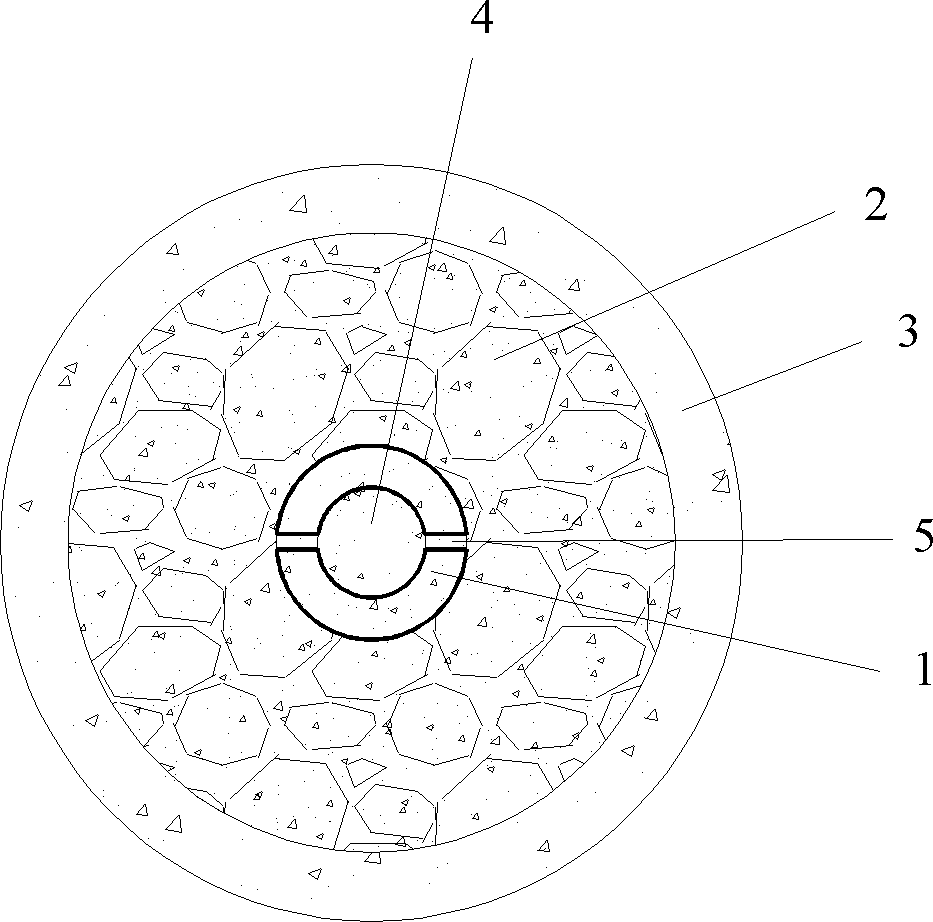

[0025] Such as figure 1 , 2 As shown in and 3, a pile with a hollow core slurry-solid-dispersion material is composed of a prefabricated pipe pile (1), a slurry-solid-dispersion material (2) and a slurry diffusion zone (3), and the interior of the prefabricated pipe pile (1) is filled with The grout (4), the prefabricated pipe pile (1) has a grouting hole (5) on the pile wall. The diameter of the pile body formed by the present invention is 500-700 mm, and the diameter of the prefabricated pipe pile (1) is 200-300 mm.

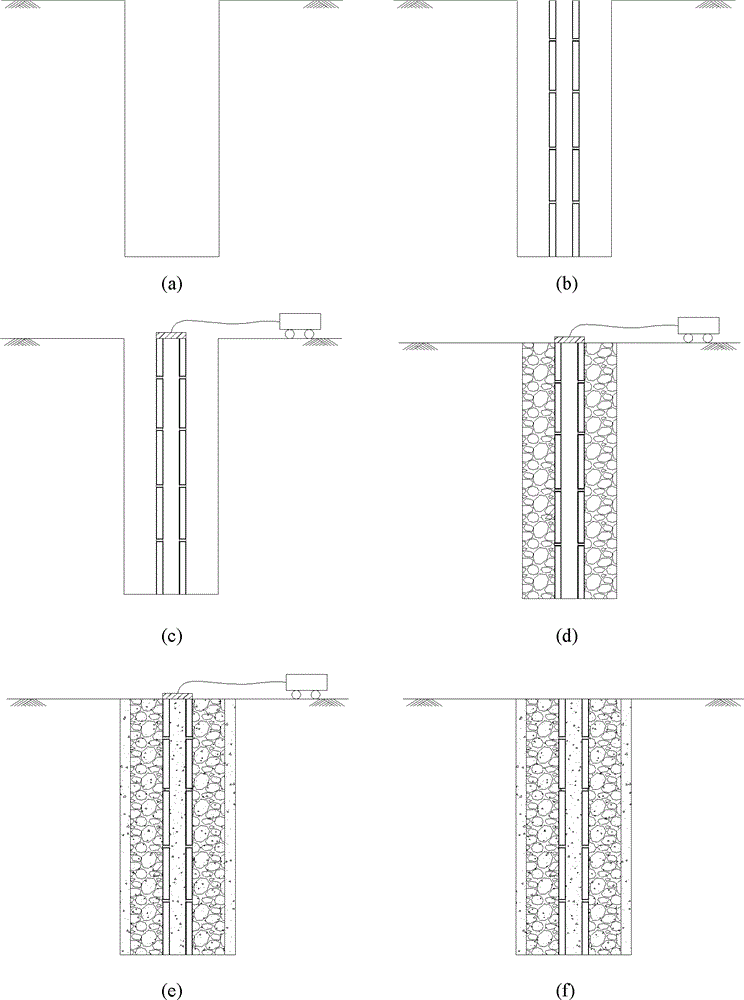

[0026] A construction method of a hollow core slurry solid-dispersion material pile, the construction steps of which are as follows:

[0027] The first step is to form a hole. The hole forming process of the grouted pile is basically the same as that of the general bored pile. Generally, a drilling rig is used to form a hole, and the natural pulping wall is used. When the hole wall is not easy to maintain, the artificial pulping wall is used. In engineerin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com