Method for manufacturing dragon ball embroidery product

A production method and embroidery technology, applied to the mechanism of embroidery machines, embroidery machines, textiles and papermaking, etc., to achieve the effects of low product cost, simple production process, and strong three-dimensional effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

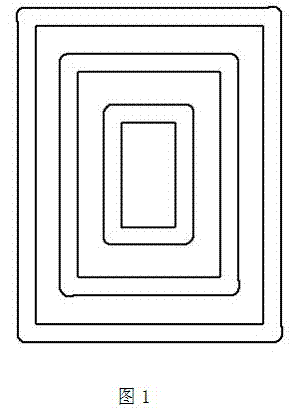

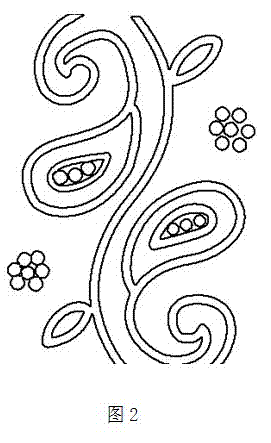

[0008] The dragon pearl embroidery sample provided by the present invention is as figure 1 , figure 2 shown.

[0009] The technological process of the Dragon Ball embroidery produced by the present invention is: design pattern plate making, embroidering samples, brushing flowers on the embroidery fabric base cloth, laser pattern making and cutting auxiliary materials, lockstitch machine embroidery, hand embroidery, embroidery washing in water, ironing, Acceptance of packaging procedures.

[0010] like figure 1 , figure 2 As shown, Dragon Ball embroidery is a combination of lines, points and surfaces.

[0011] The production method of dragon ball embroidery, which includes designing pattern plate making, embroidery samples, brushing flowers on the embroidery fabric base cloth, laser pattern making and cutting auxiliary materials, lockstitch machine embroidery, hand embroidery, embroidery washing in water, ironing, acceptance and packaging program,

[0012] According to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com