Knitting fabric containing silver fibers and manufacturing process of knitting fabric

A knitted fabric, silver fiber technology, applied in knitting, weft knitting, warp knitting and other directions, can solve the problems of antibacterial, deodorant, limited UV protection time, poor hand feel and wearing comfort, and can not withstand washing and rain. , to achieve the effect of broad prospects for promotion and application, strong hand feel and wearing comfort, and soft texture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

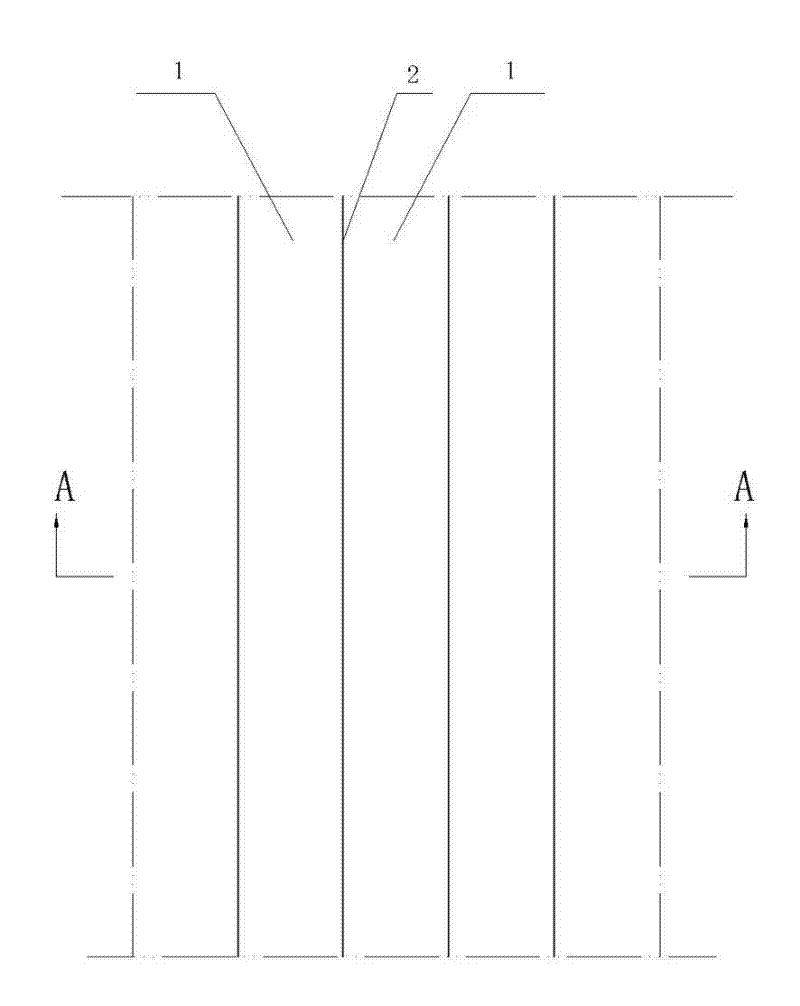

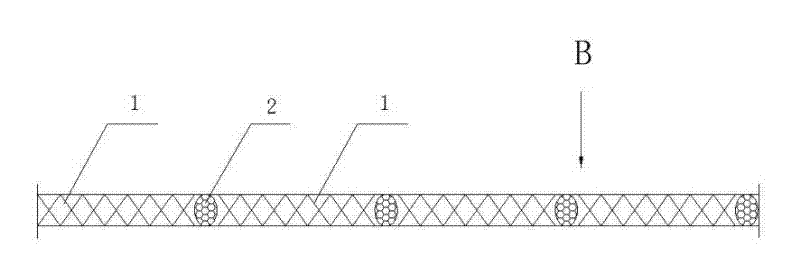

[0080] The content percentages of the above raw materials are: 85.8% of cotton yarn, 5.6% of spandex, and 8.6% of silver fiber. On the knitted fabric, the count of the cotton yarn is 60, and every seven rows of single-ply cotton yarn 1 coated with spandex is provided with a row of silver fibers 2, and the distance between two adjacent silver fibers 2 is about 7mm; And so on.

[0081] Other embodiments can refer to the following table 1:

[0082]

[0083] like Figure 4~6 Shown, a kind of knitted fabric that the present invention relates to contains silver fiber, it is by raw material: cotton, modal, spandex and silver fiber form through knitting big circular machine;

[0084] The content percentage of the above raw materials is: cotton 51.8-65.5%, modal 24-28%, spandex 3-6%, silver fiber 2-15%;

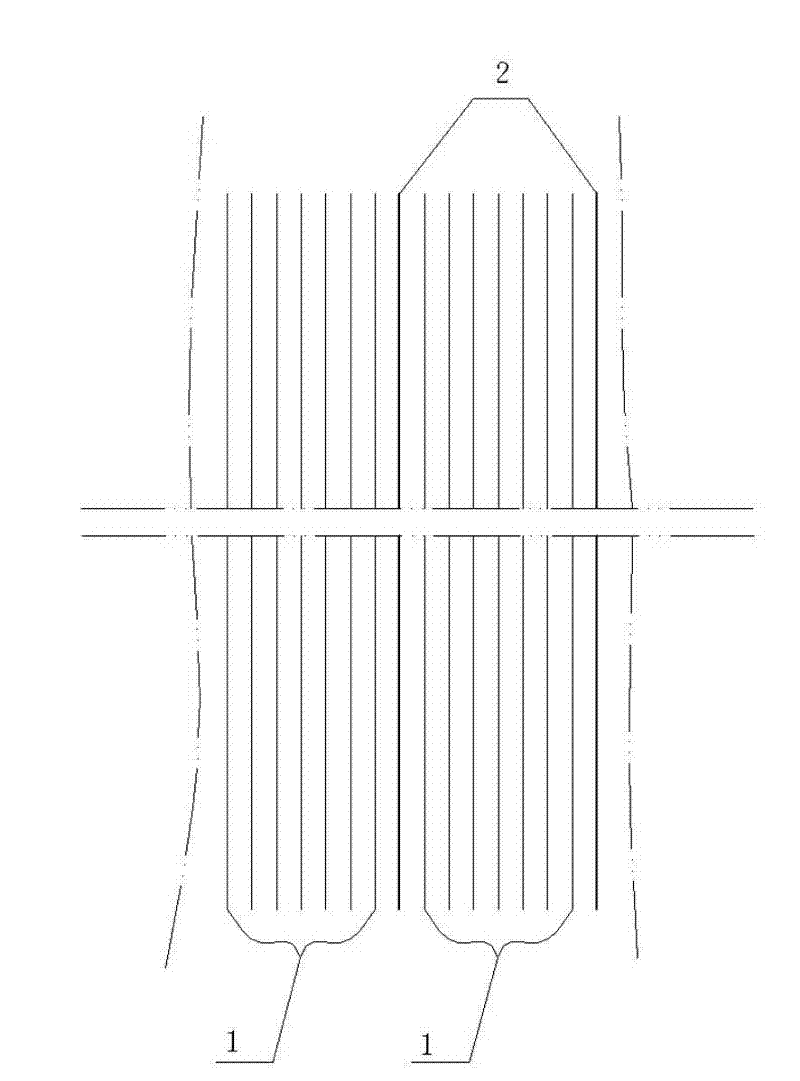

[0085] Modal coated with spandex and cotton are blended to form a single-ply yarn 3, and several single-ply yarns 3 are arranged at intervals with the oxidized silver fibers 2, ...

Embodiment 2

[0088] The content percentages of the raw materials of the present invention are: 56.8% of cotton, 25.4% of modal, 3.8% of spandex and 14% of silver fiber.

[0089] On the knitted fabric, the blended yarn count of cotton and modal is 80, and the single-ply yarn 3 that is blended with modal and cotton warp and covered with fully woven spandex is provided with a row of silver fibers 2 every five rows. The distance between two silver fibers 2 is about 5mm; and so on.

[0090] Other embodiments can refer to the following table 2:

[0091]

[0092] Except above-mentioned embodiment, the content proportioning of lining of the present invention can also be:

[0093] 20%~30% cotton, 55.8%~63.5% modal, 3~6% spandex, 2~15% silver fiber;

[0094] can also be:

[0095] Cotton 31%~40.5%, Modal 44.8%~53%, Spandex 3~6%, Silver fiber 2~15%.

[0096] It can maintain the antibacterial, deodorant, antistatic, anti-ultraviolet and anti-radiation effects of the fabric for a long time.

[0...

Embodiment 3

[0101] The content percentage of the above raw materials is: cotton 60.2%, polyester fiber 23%, spandex 5%, silver fiber 11.8%.

[0102] On the knitted fabric, the yarn count of cotton is 140, and the single-ply yarn 4 of polyester fiber and cotton warp blended and covered with fully woven spandex is provided with a row of silver fiber 2 every three rows, adjacent to each other. The distance between two silver fibers 2 is about 3 mm; and so on.

[0103] Other embodiments can refer to the following table 3:

[0104]

[0105] Except above-mentioned embodiment, the content proportioning of lining of the present invention can also be:

[0106] Cotton 20%~28%, polyester fiber 56.8%~64.5%, spandex 3~6%, silver fiber 2~15%;

[0107] can also be:

[0108] Cotton 29%~41%, polyester fiber 47.8%~51.5%, spandex 3~6%, silver fiber 2~15%.

[0109] It can also maintain the antibacterial, deodorant, antistatic, anti-ultraviolet and anti-radiation effects of the fabric for a long time. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com