Preparation method of water-soluble chitosan/polyvinyl alcohol composite films

A water-soluble chitosan, polyvinyl alcohol technology, applied in the direction of flexible covering, climate sustainability, sustainable manufacturing/processing, etc., to achieve the effects of environmental friendliness, excellent mechanical properties, and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

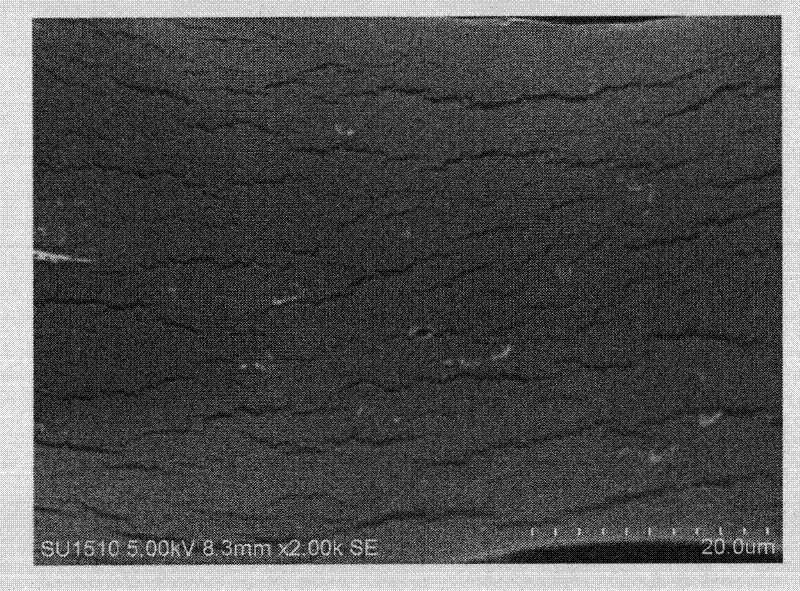

Image

Examples

Embodiment 1

[0020] The raw materials and their weight ratios are as follows: the water-soluble chitosan is 1% of N-maleoylated chitosan, the polyvinyl alcohol is 30% of PVA-0588, and the crosslinking agent is 7% of glutaraldehyde.

[0021] Add N-maleoylated chitosan to deionized water, stir and dissolve at room temperature; add PVA-0588 to deionized water, heat up to 80-95°C while stirring to dissolve; add chitosan solution to polyvinyl alcohol solution After stirring at 80-95°C to make it evenly dispersed, it is poured onto flat glass and cast to form a film. The solvent is evaporated at room temperature, immersed in glutaraldehyde solution for cross-linking for 40-60 minutes, peeled off, and dried naturally or dried to obtain a water-soluble chitosan / polyvinyl alcohol composite film.

Embodiment 2

[0023] The raw materials and their weight ratios are as follows: water-soluble chitosan is 2% of carboxymethyl chitosan, polyvinyl alcohol PVA-1788 is 10%, crosslinking agent is 3% of glutaraldehyde, and borax is 2%.

[0024] Add carboxymethyl chitosan to deionized water, stir and dissolve at room temperature; add PVA-1788 to deionized water, heat up to 80-95°C while stirring to dissolve; add chitosan solution to polyvinyl alcohol solution, 80 After stirring at -95°C to disperse evenly, pour it onto flat glass and cast it into a film. The solvent is evaporated at room temperature, immersed in a mixed solution of glutaraldehyde and borax to crosslink for 40-60 minutes, peeled off, and dried naturally or oven-dried to obtain a water-soluble chitosan / polyvinyl alcohol composite film.

Embodiment 3

[0026] Raw materials and their weight ratios are: water-soluble chitosan is hydroxypropyltrimethylammonium chloride chitosan 4%, polyvinyl alcohol is PVA-1792 40%, crosslinking agent is glutaraldehyde 3%, trimer Sodium Phosphate 2%, Epichlorohydrin 3%.

[0027] Add hydroxypropyltrimethylammonium chloride chitosan into deionized water, stir and dissolve at room temperature; add PVA-1792 into deionized water, heat up to 80-95°C while stirring to dissolve; add chitosan solution to poly In the vinyl alcohol solution, stir at 80-95°C to disperse evenly, pour it on a petri dish and cast it into a film. Volatilize the solvent at room temperature, immerse in the mixed solution of glutaraldehyde, sodium tripolyphosphate and epichlorohydrin for crosslinking for 40-60min, peel off, dry naturally or dry to obtain a water-soluble chitosan / polyvinyl alcohol composite film.

PUM

| Property | Measurement | Unit |

|---|---|---|

| alcoholysis degree | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com