On-line heating device and method for tin liquor backflow in float glass tin bath

A float glass and heating device technology, applied in the production field of ultra-thin float glass, can solve the problems affecting the flattening and thinning of glass liquid, the thickness difference and micro-corrugation can not meet the quality requirements, and the lack of temperature adjustment and liquid flow in the tin liquid reflux. Control methods and other issues to achieve the effect of improving quality, reducing lateral temperature difference, and improving tin liquid convection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention is further described in conjunction with accompanying drawing, and the manufacturing technology of this device is very clear to those skilled in the art.

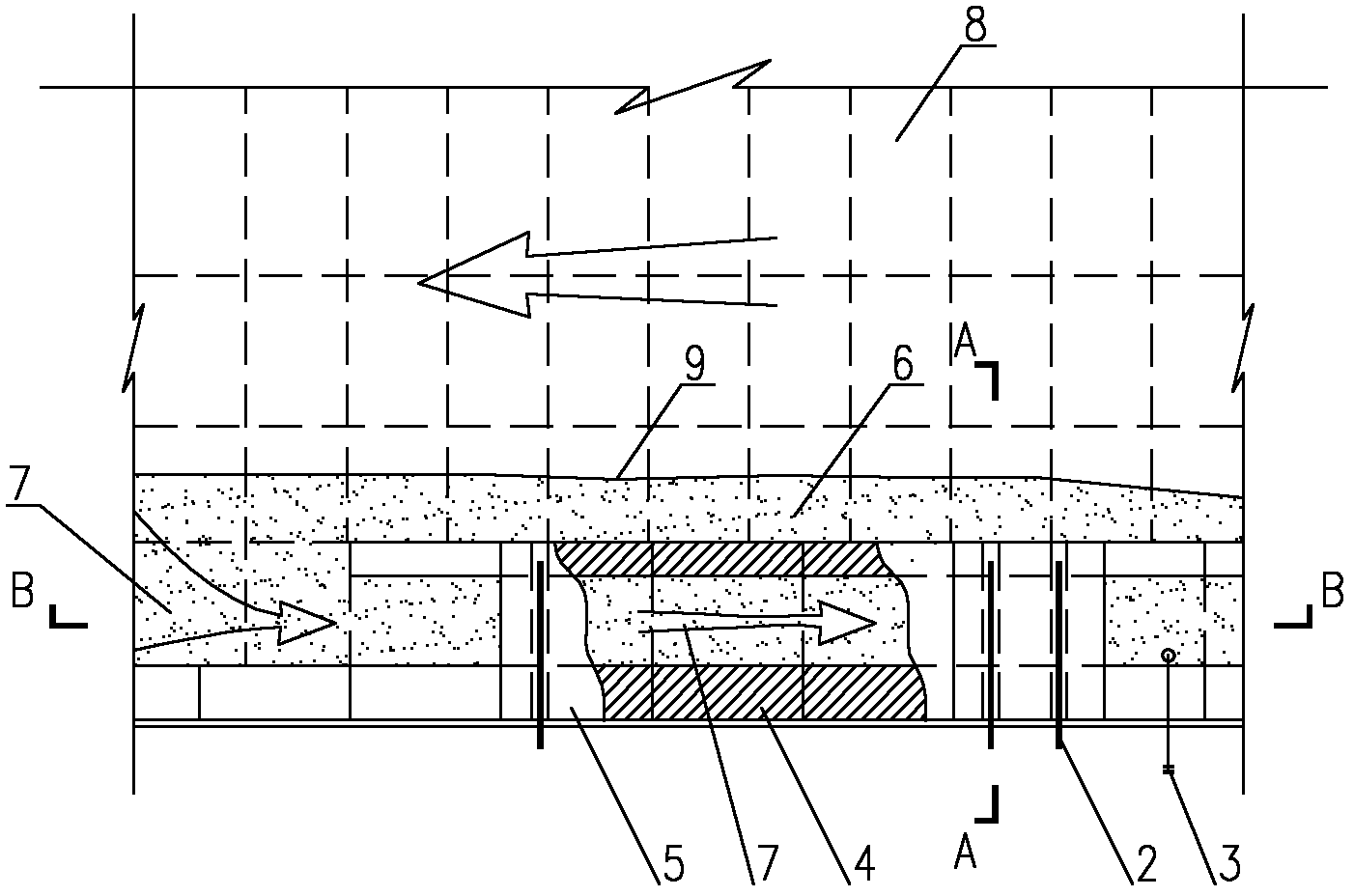

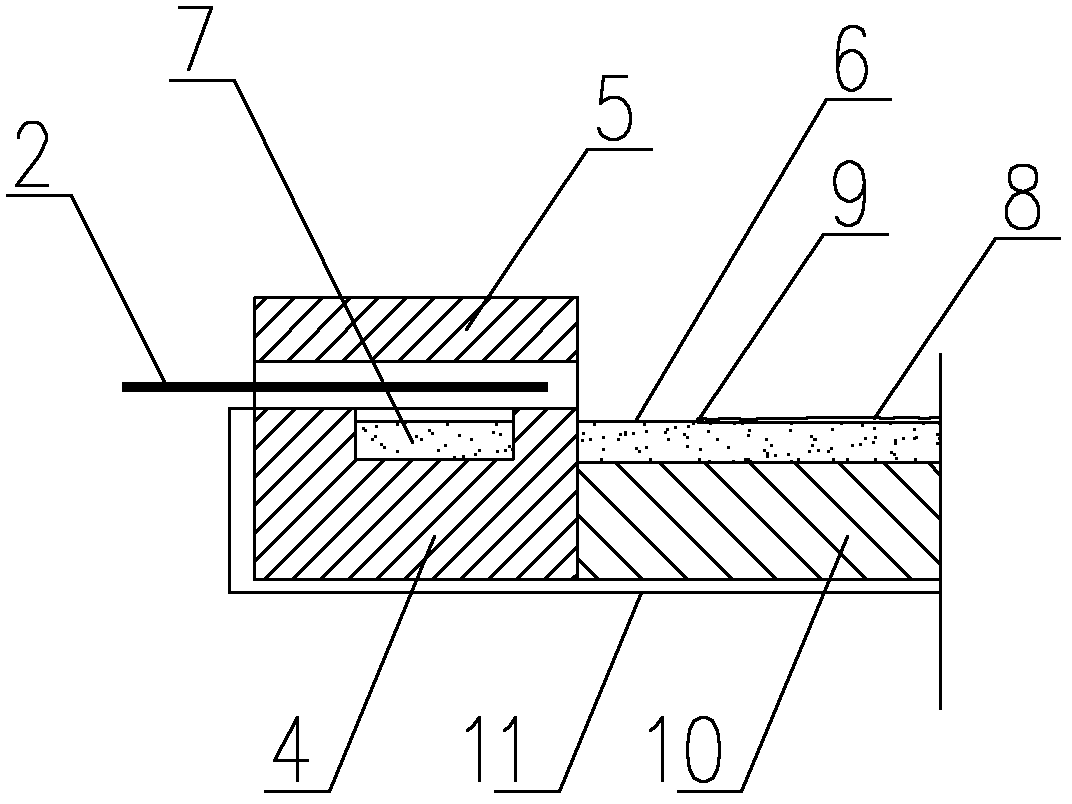

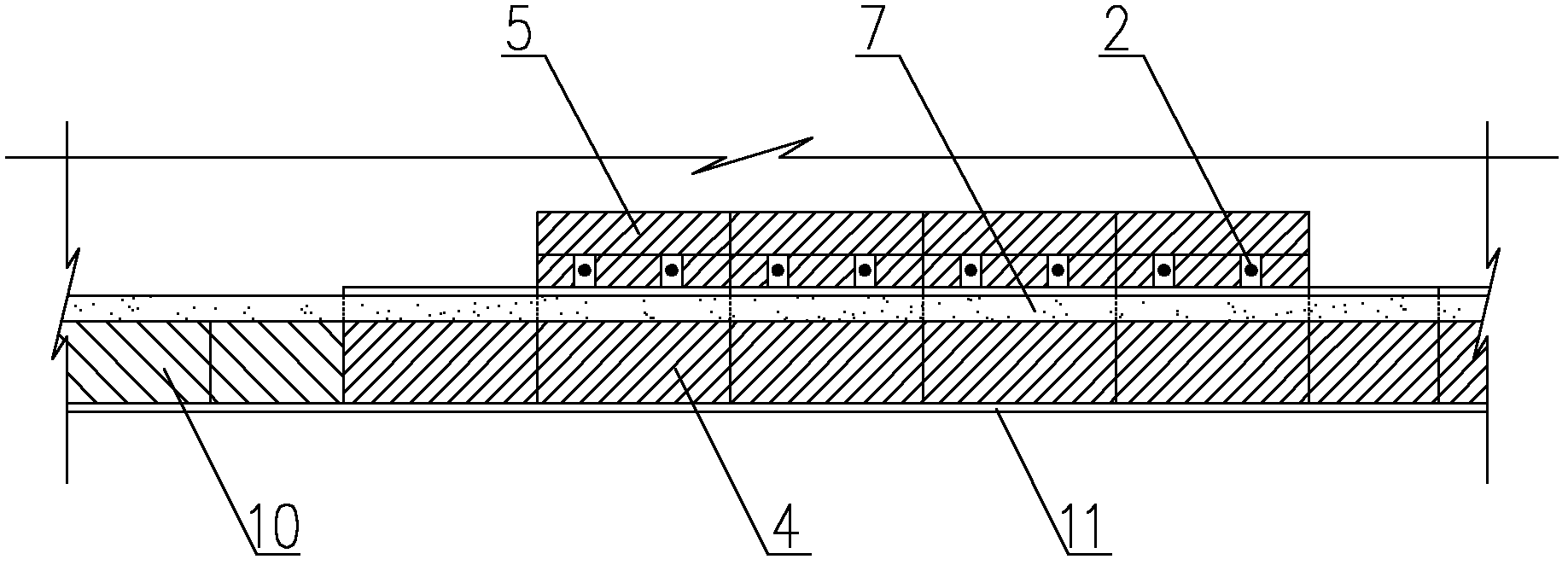

[0015] According to the method provided by the present invention, an online heating device for reflowing tin liquid in a float glass tin bath should be symmetrically arranged on both sides of the wide section of the tin bath to replace the side wall of the traditional tin bath, such as figure 1 shown. The length of the device, the configuration of electric heating, and the installation position in the tin bath should be reasonably adjusted according to different tin baths and different products produced. Through the 4-groove structure of the lower wall brick, the downstream return tin liquid of the tin tank is separated from other tin liquids, so that it is fixed in the tank and flows upstream, effectively controlling the flow direction of the tin liquid return, and adopting closed-loop control ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com