Flow control device

A technology of flow control device and diversion groove, which is used in manufacturing tools, glass manufacturing equipment, glass furnace equipment, etc. The effect of improving the yield of good products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

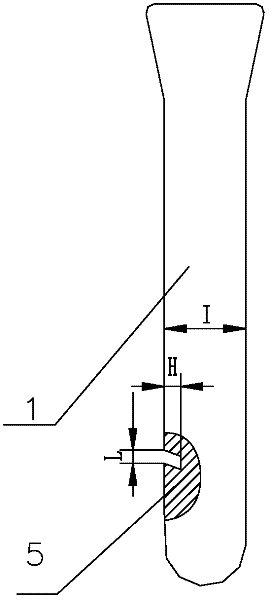

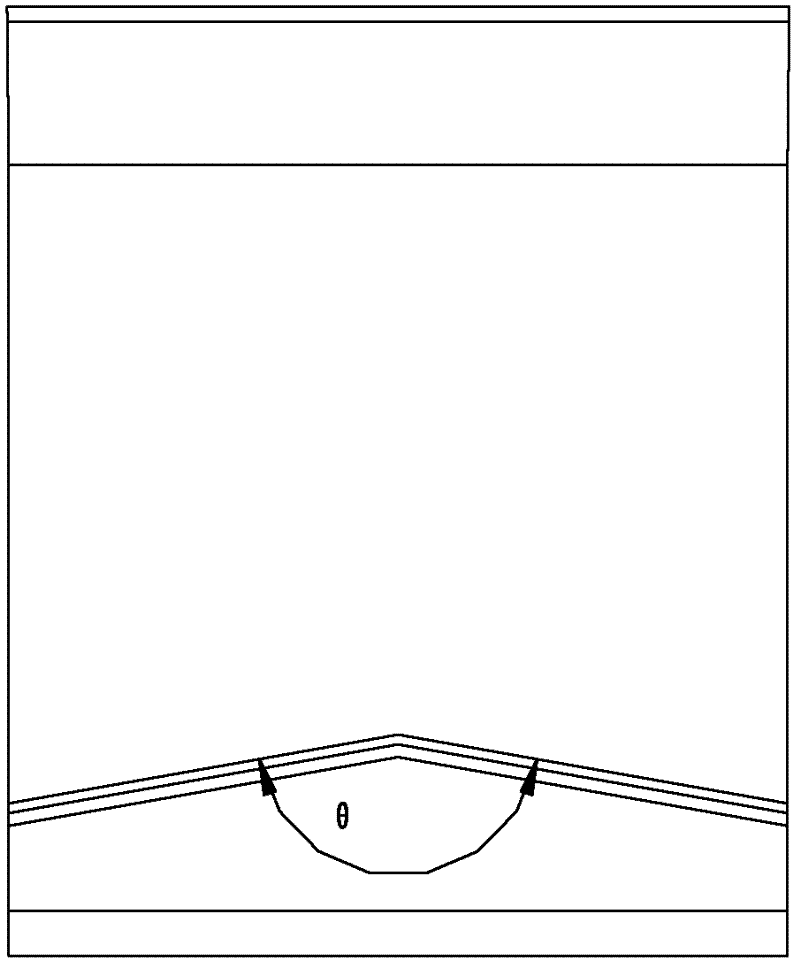

[0017] In the present invention, a diversion structure is arranged on the flashboard 1 . The diversion structure is that a diversion groove 5 is arranged on one side of the flashboard 1, such as figure 1 and figure 2 shown. The diversion groove 5 is preferably a herringbone groove with an upward slant, and the top of the herringbone is located in the middle of the gate 1 . The herringbone angle θ of the diversion groove 5 is 120-170°, preferably 160°; the width L of the diversion groove 5 is 10-100mm, and the preferred width is 57mm; the depth H of the diversion groove 5 does not exceed the gate 1 / 4 of the thickness I of plate 1. Through the guide groove 5, the droplets formed by the volatile condensation of the molten glass 3 and the adhesion of tin ash can be guided to both sides of the channel.

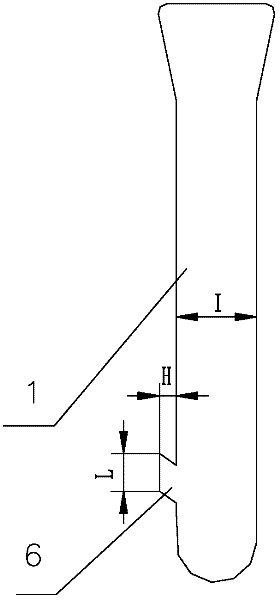

[0018] The above-mentioned diversion structure can also be provided with a diversion protrusion 6 on one side of the shutter 1, such as image 3 and Figure 4 shown. The di...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com