Activated oyster shell biofilm carrier prepared from oyster shells serving as raw material

A technology of biological filler and oyster shell, applied in the direction of sustainable biological treatment, biological water/sewage treatment, chemical instruments and methods, etc., can solve the problems of changing mold hanging effect, complicated debugging process, high cost of raw materials, etc., and achieve saving chemical raw materials , improve the chance of survival, good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

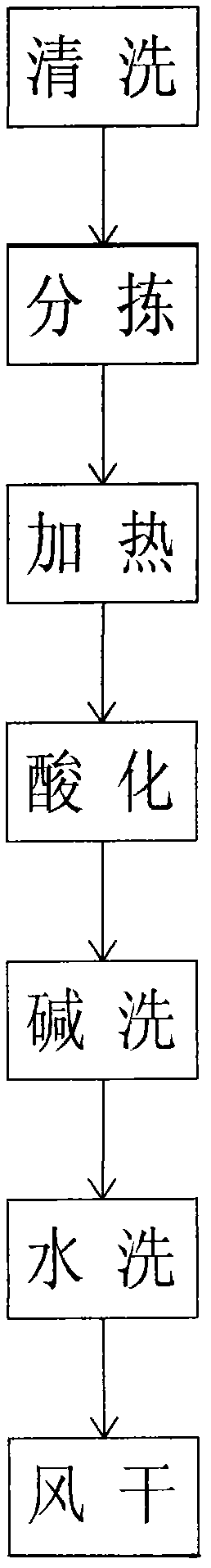

[0020] Specific implementation mode one: as figure 1 Shown, a kind of activated oyster shell biological filler with oyster shell as raw material, this biological filler is with oyster shell as raw material, and its preparation steps are:

[0021] (1) Cleaning: put the oyster shell raw material in a container, add water to the container, and carry out aeration and scouring for 30 minutes by a blower to remove the attachments on the surface of the oyster shell;

[0022] (2) Sorting: Sorting the oyster shells after aeration and scouring, removing broken oyster shells and oyster shells with a size less than 5cm;

[0023] (3) Heating: Put the sorted oyster shells into a closed container, and use the heat source generated by the steam boiler to heat treatment. The heating temperature is 50°C, and the heating time is 30 minutes;

[0024] (4) Acidification: the oyster shell after heat treatment is put into the container that is filled with sulfuric acid to carry out acidification, an...

specific Embodiment approach 2

[0028] Embodiment 2: Different from Embodiment 1, in Embodiment 2, the heating temperature of step (3) heat treatment is 60° C., and the pH value is adjusted to 7 during step (5) alkaline washing.

specific Embodiment approach 3

[0029] Embodiment 3: Different from Embodiment 1, in Embodiment 3, the heating temperature of step (3) heat treatment is 70° C., and the pH value is adjusted to 7.5 during step (5) alkaline washing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com