Method for purifying hydrocyanic acid from mixed gas containing hydrocyanic acid

A technology containing hydrocyanic acid and mixed gas, applied in the chemical industry, can solve the problems of low purification efficiency of hydrocyanic acid, low concentration of hydrocyanic acid, low absorption temperature, etc., shortening the rectification time, improving purification efficiency and energy consumption reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] Example 1. Pure hydrocyanic acid from the reaction of hydrocytic acid synthesis of hydrocyric acid

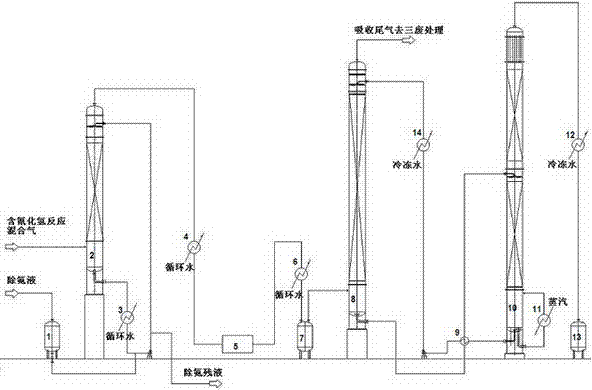

[0015] Device schematic diagram figure 1 Show.

[0016] a.Ammonia removal: Add ammonia removal solution to the ammonia removal liquid meter 1 (sulfate solution with pH 4), and the reaction gas of the Anshisa synthesized hydrocyanic acid is passed into the ammonia removal tower 2 from the bottom.2 Spray the ammonia removal liquid at the top, and react with the mixture of the mixture to remove the ammonia contained in the ammonia.After the ammonia liquid is used by the ammonia removal cooler 3, it is used after cooling, and the new ammonia removal solution is replaced regularly;

[0017] b.Absorption: Press the reaction mixture after removing the reaction of ammonia to 0.7MPa, and then cool down through a pressurized mixed gas cooler 6 to 45 ° C to pass the pressure mixed air buffer 7;The pressure hybrid gas in the tank 7 uses a constant pressure 0.7MPa from the bottom of the ...

Embodiment 2

[0019] Example 2. Purify hydrocyanic acid from the reaction of hydrocytic acid synthetic hydrocyanic acid

[0020] The difference between this embodiment and Example 1 is:

[0021] In the absorption step, the pressure of the control pressure absorption tower 8 is 0.3MPa, the temperature is 25 ° C, and finally obtains a hydrocyanic acid absorption solution with a concentration of 52g / L.

Embodiment 3

[0022] Example 3. Purify hydrocyanic acid from the reaction of hydrocytic acid synthesis of hydrocyric acid

[0023] The difference between this embodiment and Example 1 is:

[0024] In the absorption step, the pressure of the control pressure absorption tower 8 is 0.5MPa, the temperature is 28 ° C, and finally obtains a hydrocyanic acid absorption solution with a concentration of 72g / L.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com