Large-load liftable workbench

A technology for lifting worktable and large load, applied in the direction of lifting frame, lifting device, etc., can solve the problems of high cost, simple and cost-effective combination structure of cylinder connecting rod, and cumbersome direct drive mechanism of cylinder, and achieves good bearing capacity and difficult processing. Small, inexpensive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

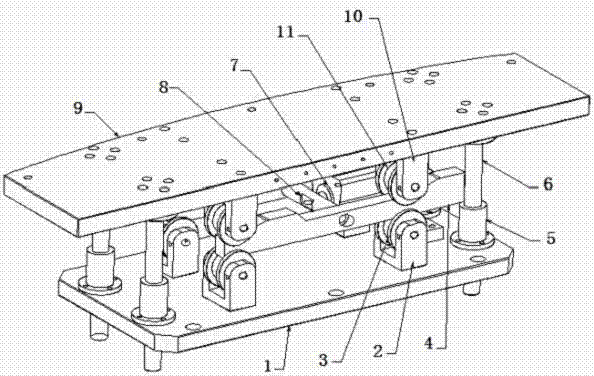

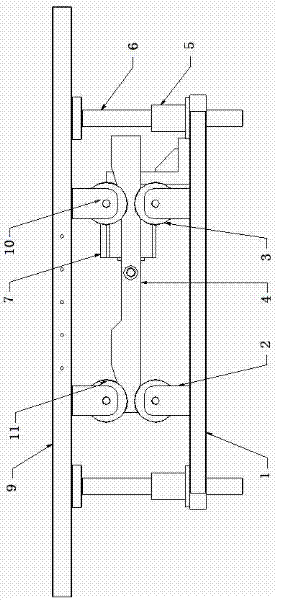

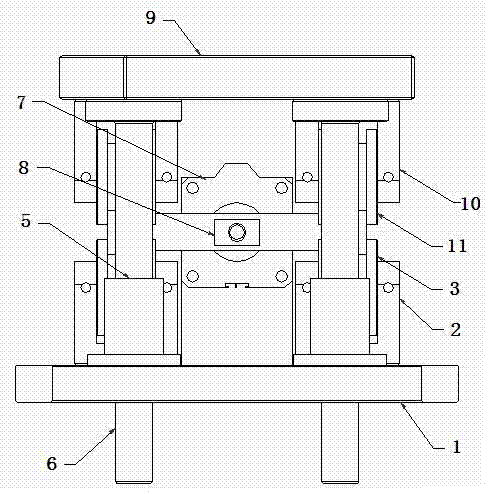

[0016] The present invention will be described in detail below with reference to the accompanying drawings and in combination with embodiments.

[0017] see figure 1 As shown, a large-load liftable workbench includes a bottom support plate 1 and a worktable panel 9, the upper part of the bottom support plate 1 is provided with four first guide roller support seats 2, and the four guide roller support A first guide roller 3 is respectively arranged in the seat 2, and four second guide roller support seats 10 are provided at the bottom of the table panel 9, and a second guide roller support seat 10 is respectively provided in the four second guide roller support seats 10. Guide roller 11, described bottom support plate 1 is also provided with a cylinder 7, is fixed with rail push rod 8 on described cylinder 7, and the two ends of described rail push rod 8 are respectively fixed with special-shaped guide rail 4, and described special-shaped guide rail 4 is set between the first ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com