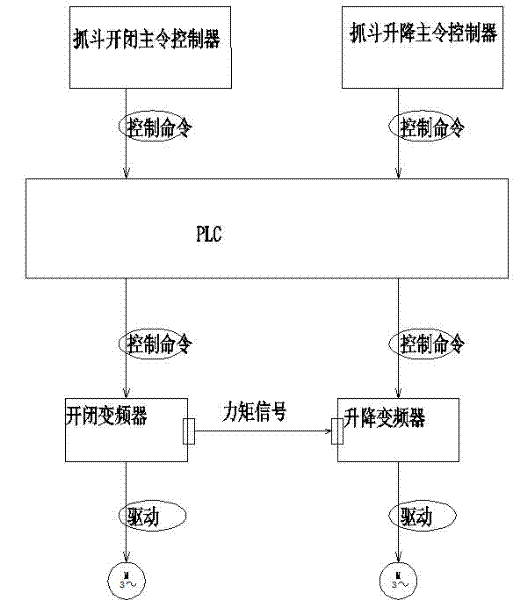

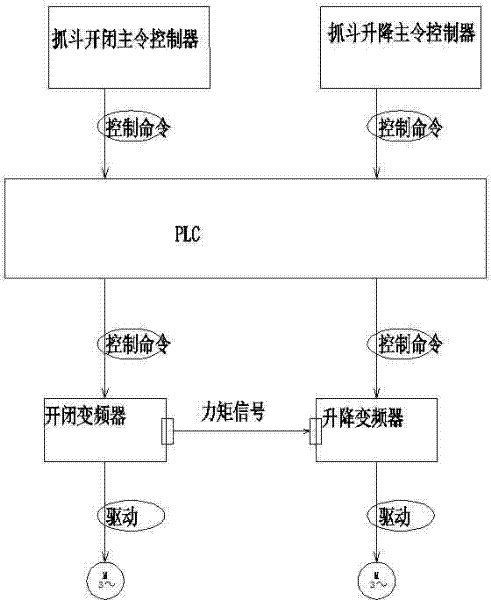

Quick following control method for lifting motor and opening and closing motor of grabbing crane

A lifting motor and follow-up control technology, applied in the direction of load hanging components, transportation and packaging, etc., can solve the problem of unfavorable and safe operation of the opening and closing motor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0010] The details of the feeding and discharging process of the grab bucket are as follows:

[0011] 1) When the grab bucket descends to the material surface, the pull rope of the opening and closing motor is tightened, and the grab is closed to grab the material. At this time, the opening and closing motor is in the speed control mode; the lifting motor is closed, but its brake is opened. As the material increases, The lifting rope descends with the gravity, and the grab automatically grabs the material under the action of gravity.

[0012] 2) When the material is fully grasped and the grab is closed, the lifting process starts. At this time, due to the slackness of the lifting motor rope, the lifting motor works in the speed control mode of constant speed, and the lifting motor quickly accelerates to the set speed. The set speed should be as large as poss...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com