Device for stacking glass by mechanical arm and positioning method of device

A technology of stacking device and positioning method, which is applied in the direction of stacking, transportation and packaging of objects, can solve the problems of positioning, poor accuracy and uneven stacking of the first piece of glass.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention is described further in conjunction with accompanying drawing, and the manufacturing technology of this device is very clear to those skilled in the art.

[0022] In conjunction with the accompanying drawings, the implementation of the present invention is provided as follows:

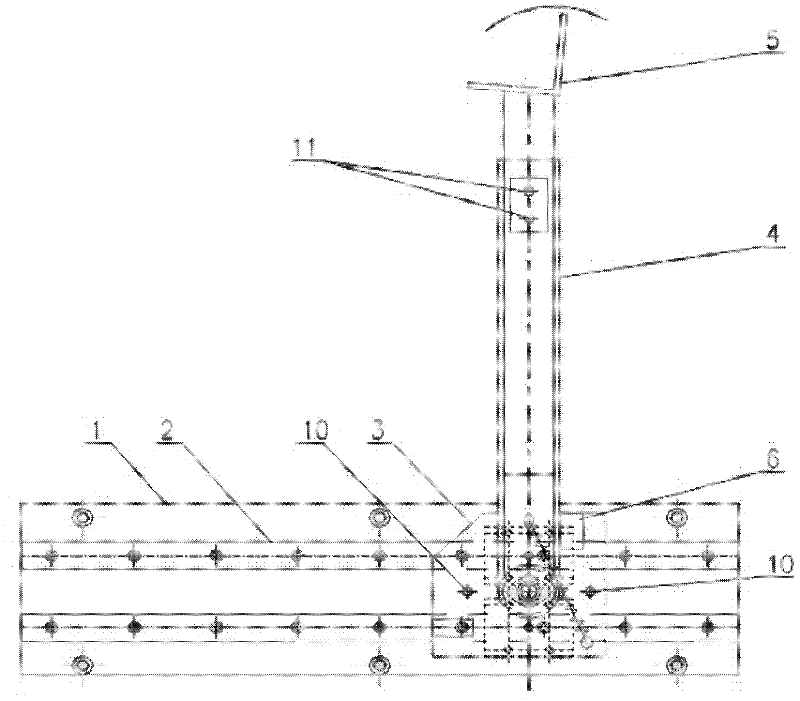

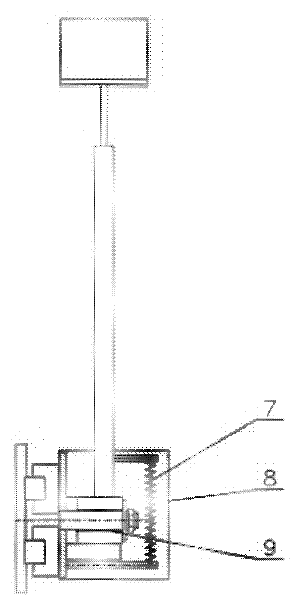

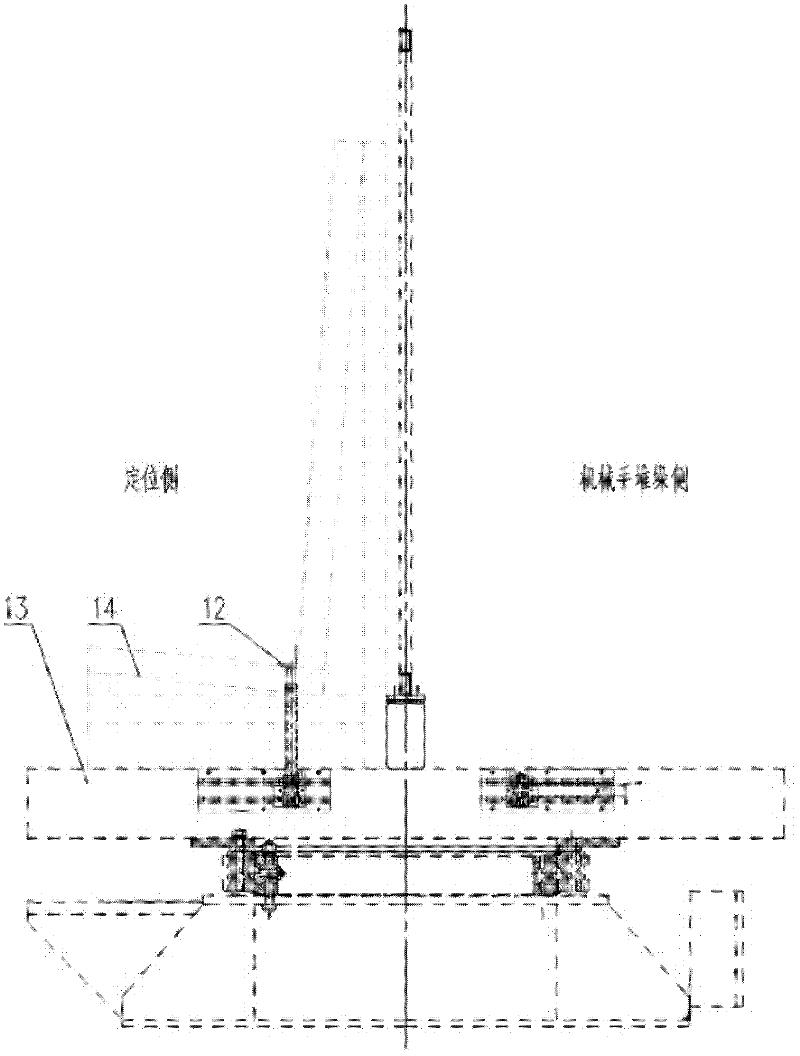

[0023] Such as figure 1 , 2 , 3, the present invention includes an L-shaped scale 12, a rotating platform 13, and a glass pallet 14, and is characterized in that four positioning devices are arranged on both sides of the rotating platform 13, and the positioning devices include a rotating connection Rod 4, Y-shaped scale connecting rod 5, sliding base 3, double guide rails 2, two sliders are arranged on the double guide rails 2, the sliding base 3 is connected with the sliders, and the rotating connecting rod 4 is connected to slide through sliding bearings The base 3, the Y-shaped scale pole 5 are installed and fastened with the rotating connecting rod 4 through the set ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com