Automatic anti-tilting control system for automotive hydraulic lifting

An automatic control system and hydraulic technology, applied in the direction of motor vehicles, vehicle components, vehicle safety arrangements, etc., can solve the problems of economic loss of units or users, improper operation of operators, lack of work experience, etc., to reduce the rollover rate of vehicles, The effect of reducing rollover accidents and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

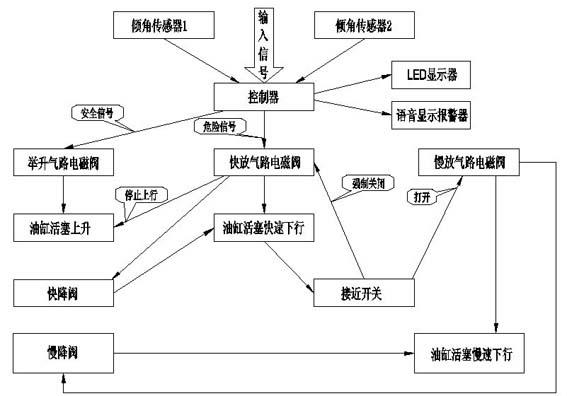

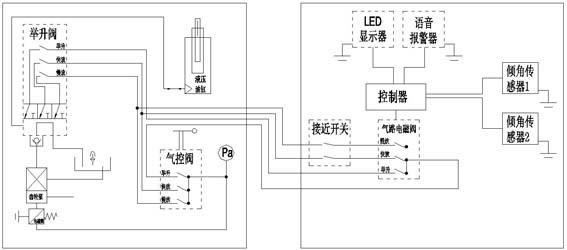

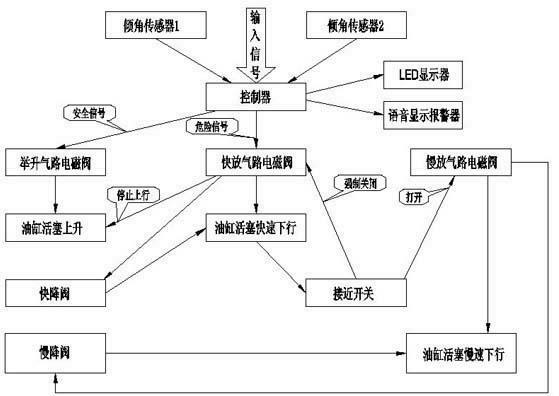

[0020] Such as figure 1 , 2 As shown, the automobile hydraulic lift anti-tilt automatic control system includes a lift valve, a single-chip microcomputer controller, an inclination sensor, a proximity switch, a lift air circuit solenoid valve, a fast release air circuit solenoid valve, a slow release air circuit solenoid valve and a voice display Alarm. The inclination sensor is arranged on the vehicle body or the chassis frame, and the proximity switch is arranged on the chassis subframe, and the sensing head part of the proximity switch corresponds to the trajectory of the cargo compartment during the lifting process. The lift air circuit solenoid valve is connected to the lift air control port of the lift valve through the air pipe, the quick release air circuit solenoid valve is connected to the quick release air control port of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com