Welding equipment and use method thereof

A welding equipment and welding torch technology, which is applied in the field of welding equipment for narrow-gap automatic welding in the main circuit of nuclear power plants, can solve the problems of complicated replacement, complicated gas circuit, and unfavorable adjustment by operators, so as to reduce the space requirement for welding and ensure the The effect of welding quality and improving environmental protection benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

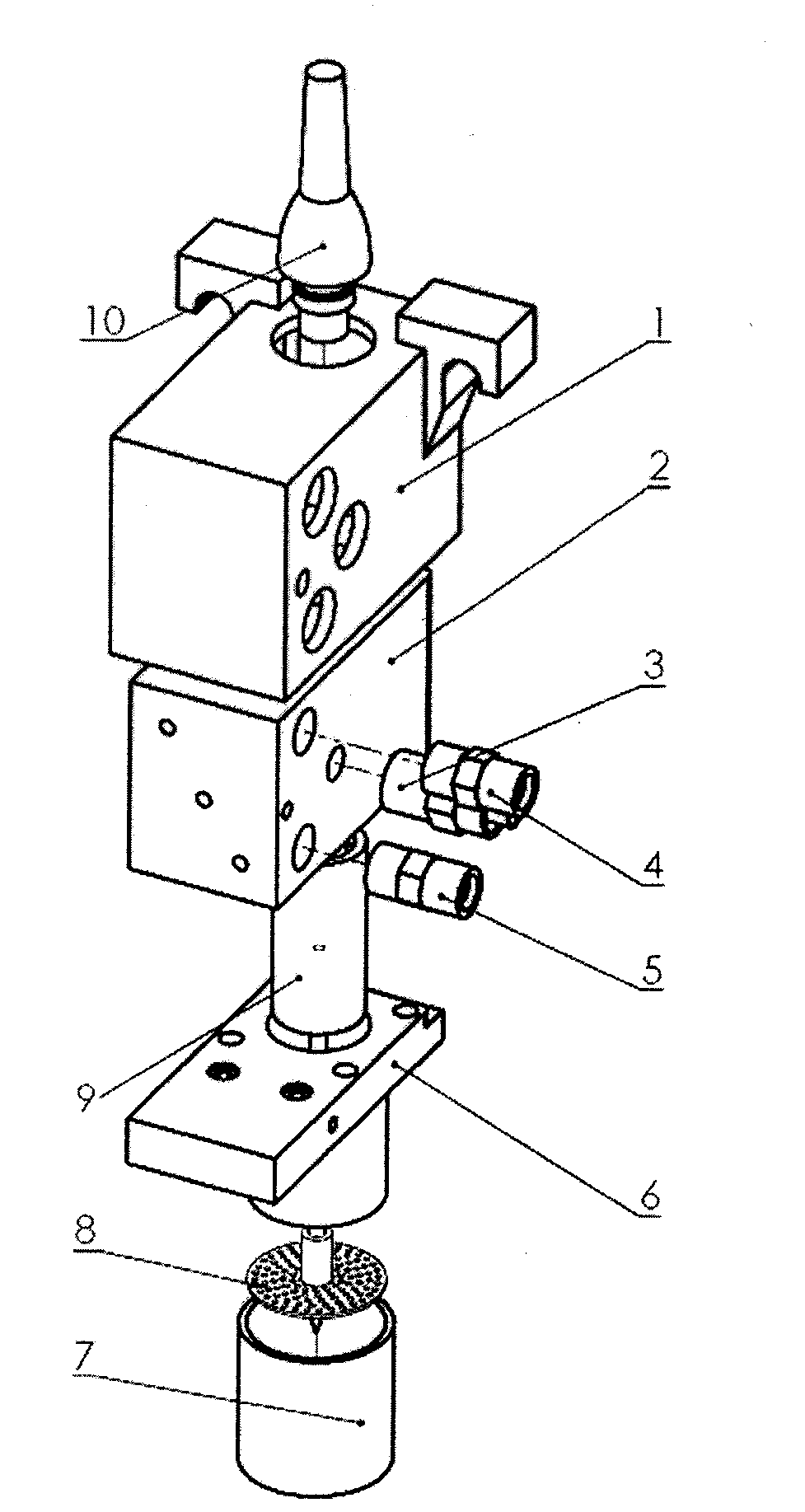

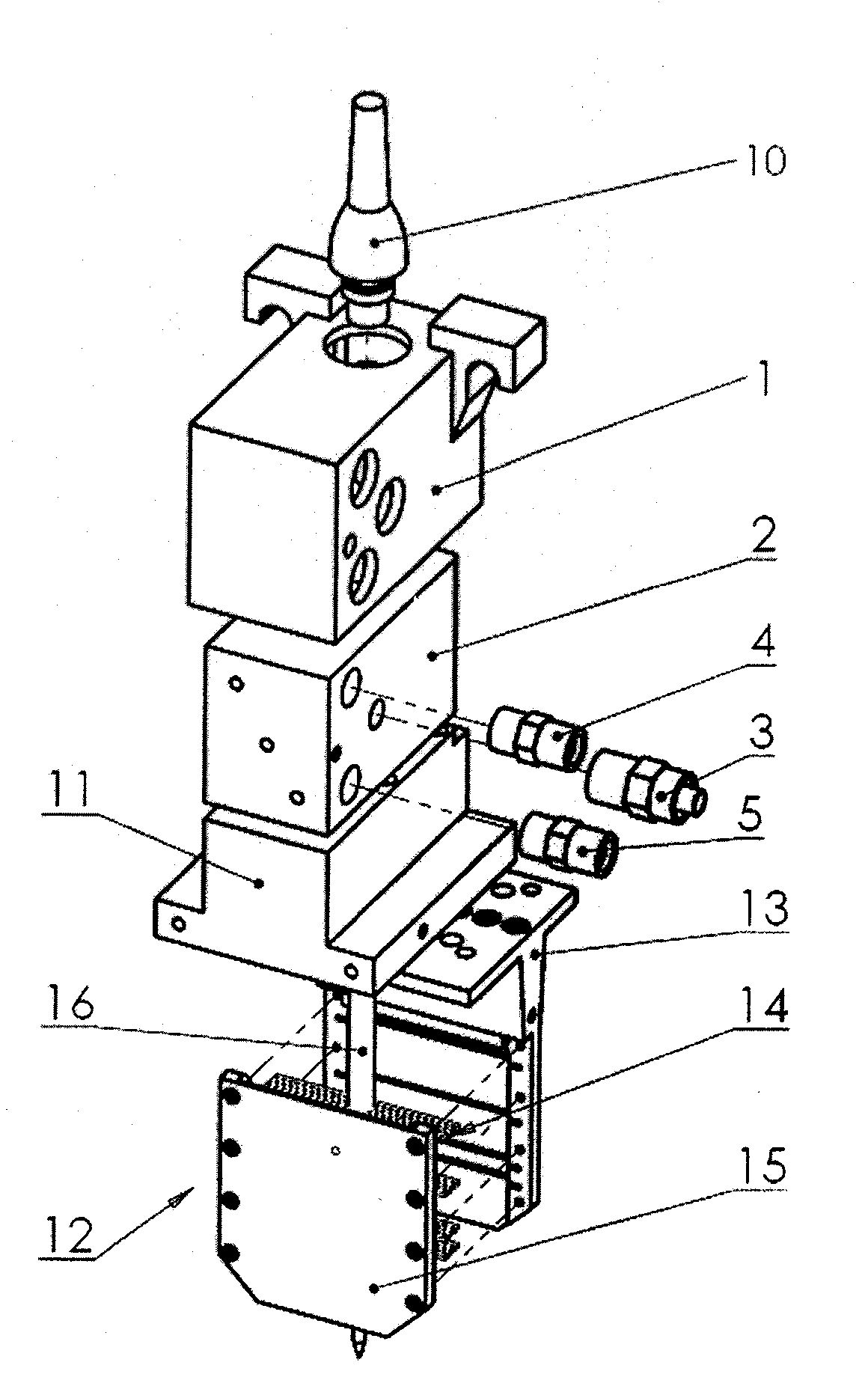

[0033] Welding equipment of the present invention is equipped with two kinds of welding torches, namely as figure 1 Standard torches shown and as figure 2 The flat welding torch shown. When the welding seam is deep, the flat welding torch is used first, that is, the welding equipment is installed as figure 2 The flat welding torch shown is used for welding; when the welding seam reaches a certain height, that is, when the welding seam is shallow, change it figure 1The standard torch shown continues to weld until the weld is complete. For workplaces with narrow welds, especially for the main circuit of nuclear power plants, after a large number of calculations and experimental results, the inventor found that when the weld depth is ≥ 25-30mm, use a flat welding gun to perform close-range protection welding on the molten pool; As the weld seam is continuously filled, when the weld seam depth is <25-30mm, replace it with a standard welding torch for welding. This welding eq...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com