Method for processing mould cavity for wheel cover of automobile

A processing method and technology of wheel cover, applied in electric processing equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of dimensional deviation, unstable quality, difficult processing, etc., and achieve the effect of long mold life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Embodiments of the present invention are described in detail below in conjunction with accompanying drawings:

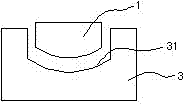

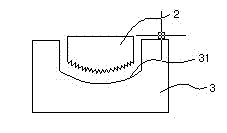

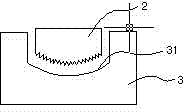

[0020] Such as figure 1 and figure 2 Shown, the processing method of a kind of automobile wheel cover mold cavity of the present invention, it comprises:

[0021] Step 1: making a first electrode 1 with a curved surface, and making the curved surface at the front end of the first electrode 1, and making a second electrode 2 with lines, and making the lines at the front end of the second electrode 2;

[0022] Step 2: process the processing surface 31 of the mold cavity 3 into a circular arc by using a spark machine through the first electrode 1;

[0023] Step 3: Using the second electrode 2 to form lines on the arc-shaped processing surface 31 of the mold cavity 3 by using a spark machine.

[0024] Preferably, in order to accurately determine the depth of the lines formed by the second electrode 2 on the processing surface 31 of the mold cavity 3, between t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com