Preparation method for aerogel for adsorbing nitrocompound

A nitro compound, aerogel technology, applied in silicon compounds, chemical instruments and methods, adsorbed water/sewage treatment, etc., can solve the problems of difficult regeneration, limited use range of activated carbon, short service life, etc., and achieve good hydrophobic performance. , the experimental environment is not complicated, the effect of good hydrophobic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0025] 14.7ml of tetramethyl orthosilicate, 7.2ml of deionized water, 68ml of absolute ethanol and 2ml, 4ml, 6ml, 8ml, 10ml, 12ml, 14ml, 16ml of methyltriethoxysilane (MTES) and A mixed solution of 0.3ml of hydrochloric acid (1mol / L) was heated at 40°C with constant stirring, and after 60min, aqueous ammonia was added to adjust the pH to 7.5. Continue to stir for 60 min to make it undergo polycondensation reaction, and finally leave it to stand to form a wet gel. The wet gel was replaced with absolute ethanol for solvent replacement every 24 hours for a total of 3 times. Finally, after drying, the hydrophobic SiO 2 airgel.

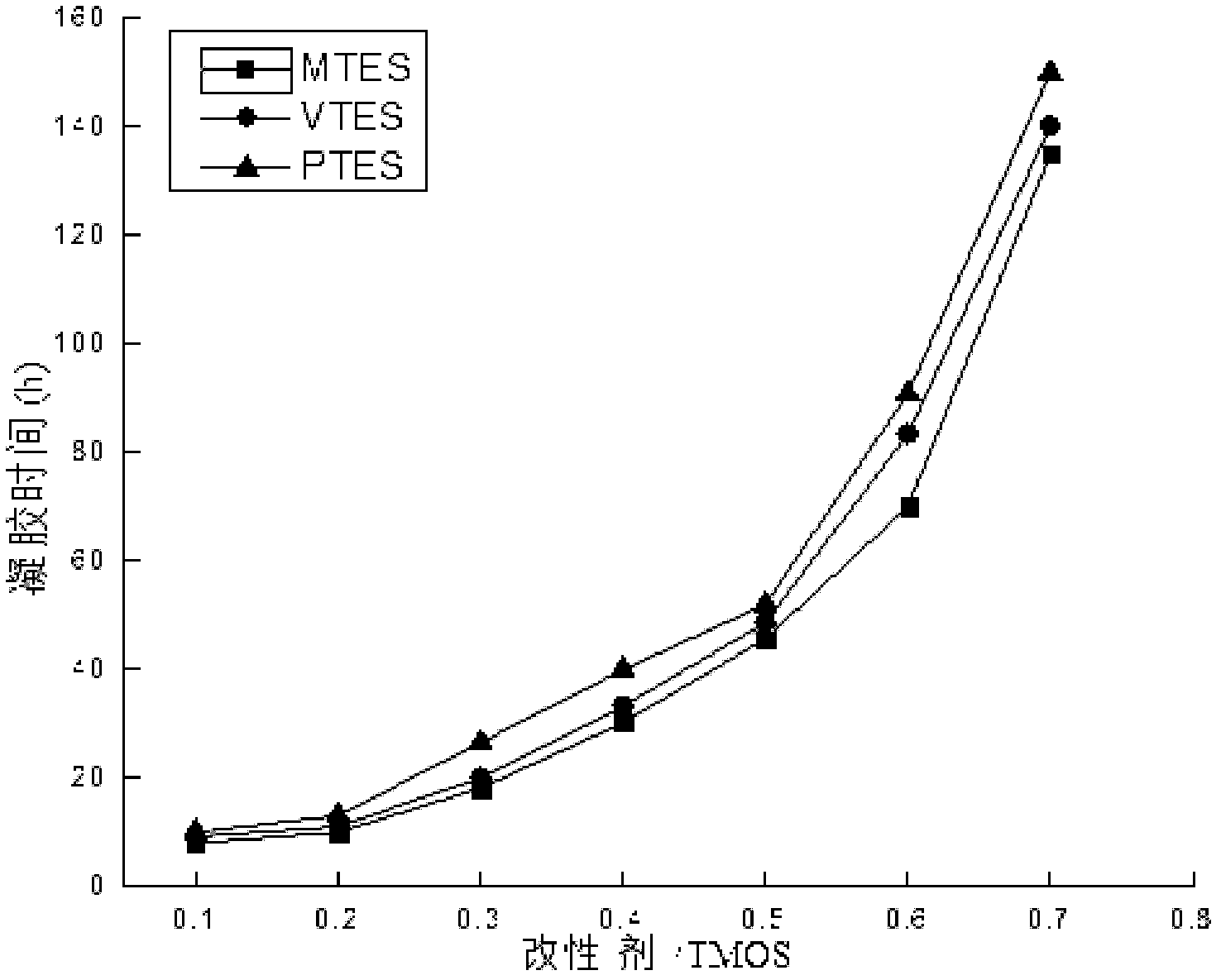

[0026] figure 1 middle For the influence of different molar ratios of MTES / TMOS on the gel time in the hydrophobic airgel prepared in Example 1, it can be seen from the figure that the larger the molar ratio, the longer the gel time.

example 2

[0028] Mix 14.7ml tetramethyl orthosilicate, 14.4ml deionized water, 93ml absolute ethanol and 2.4ml, 4.8ml, 7.2ml, 9.6ml, 12ml, 14.4ml, 16.8ml, 19.2ml of phenyltriethyl A mixed solution of oxysilane (PTES) and 0.3ml of nitric acid (1mol / L) was heated at 50°C with constant stirring, and after 40min, sodium hydroxide was added to adjust the pH to 7.5. Continue to stir for 70min to make it undergo polycondensation reaction, and finally let it stand to form a wet gel. The wet gel was replaced with absolute ethanol for solvent replacement every 12 hours for a total of 4 replacements. Finally, after drying, the hydrophobic SiO 2 airgel.

[0029] figure 1 middle For the influence of different molar ratios of PTES / TMOS in the hydrophobic airgel prepared in Example 2 on the gel time, it can be seen from the figure that the larger the molar ratio, the longer the gel time.

example 3

[0031] Mix 14.7ml tetramethyl orthosilicate, 7.2ml deionized water, 68ml absolute ethanol and 1.53ml, 3.06ml, 4.59ml, 6.12ml, 7.65ml, 9.18ml, 10.71ml, 12.24ml of vinyl tri The mixed solution of ethoxysilane (VTES) and 0.8ml acetic acid was heated at 50°C with constant stirring, and after 70min, potassium hydroxide was added to adjust the pH value to 7.5 respectively. Continue to stir for 40min to make it undergo polycondensation reaction, and finally let it stand to form a wet gel. The wet gel was replaced with absolute ethanol for solvent replacement every 24 hours for a total of 5 times. Finally, after drying, the hydrophobic SiO 2 airgel.

[0032] figure 1 middle For the influence of different molar ratios of VTMS / TMOS on the airgel in the hydrophobic airgel that example 3 makes, it can be seen from the figure that the gel times of the three modifiers all vary with the mol ratio of the modifier / TMOS The increase of , and the gel time of the three are the same.

[003...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com