Preparation method of amino-containing energetic material graded microspheres

A technology of microspheres and amino groups, applied in the field of micro-nano materials, can solve the problems that the preparation method cannot be directly introduced into use, and the hierarchical structure is difficult to be prepared, and achieves the effects of easy control of size and shape, low cost, and uniform size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

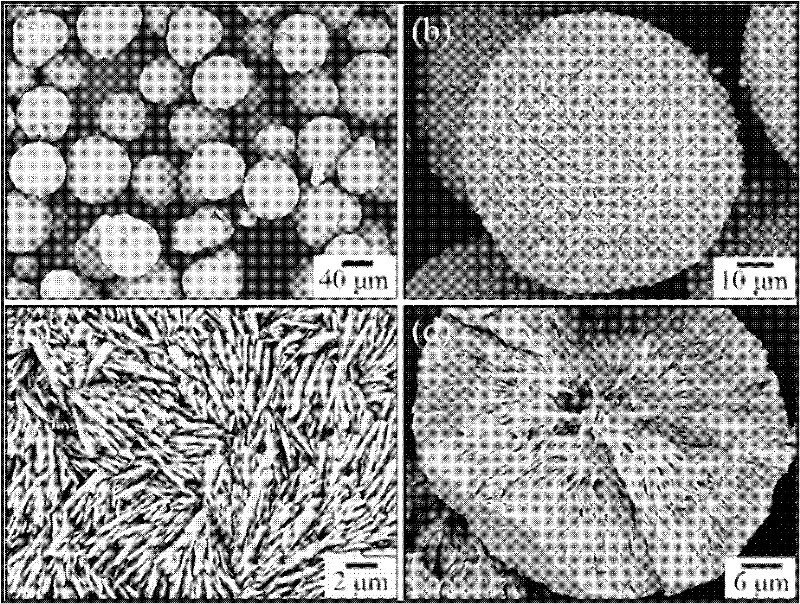

[0031] 2,6-diamino-3,5-dinitropyrazine (ANPZ, C 4 h 4 o 4 N 6 ) preparation of graded microspheres, the specific steps are:

[0032] 1) Dissolve 0.48g (8mmol) urea in 50mL absolute ethanol at room temperature, then add 0.222g (monomer molarity is 2mmol) surfactant PVP-K30, stir to obtain a light yellow solution;

[0033] 2) 0.046g (0.2mmol) precursor 2,6-dimethyl-3,5-dinitropyrazine (DMDP, C 6 h 6 o 6 N 4 ) into the solution obtained in step 1), and stirred at 35°C until the DMDP was completely dissolved to obtain a yellow transparent solution, which was transferred to a stainless steel autoclave lined with polytetrafluoroethylene, and then the autoclave was sealed and placed in a blast Oven, the temperature of the oven is 120°C, the ammonia gas produced by the alcoholysis of urea reacts with DMDP, and the reaction time is 9 hours. After the reaction is completed, the solid product is naturally precipitated and separated, and washed alternately with ultrapure water and ...

Embodiment 2

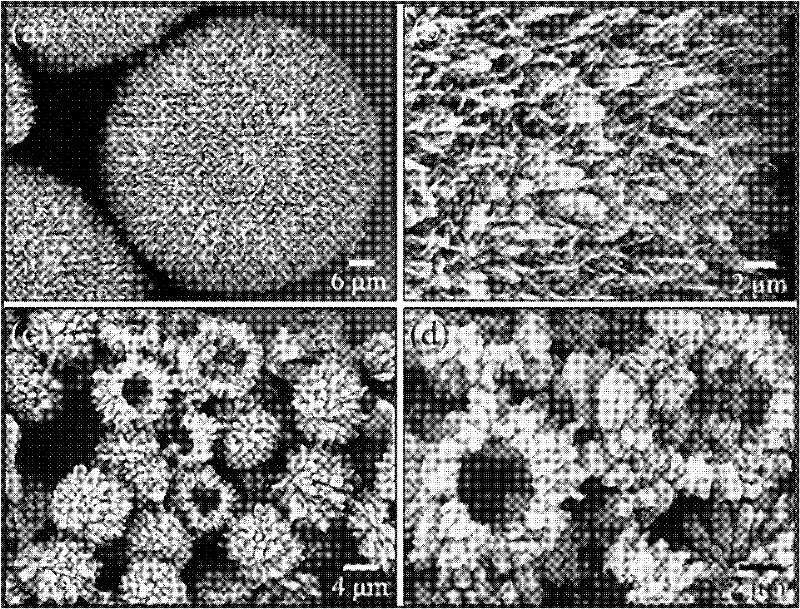

[0035]Same as Example 1, except that the autoclave is sealed and placed in an oil bath, and kept warm for 9 hours under stirring conditions to obtain ANPZ graded microspheres with a size of about 10 μm, which is smaller than the microspheres in Example 1. The SEM image Such as figure 1 Shown in c and d.

Embodiment 3

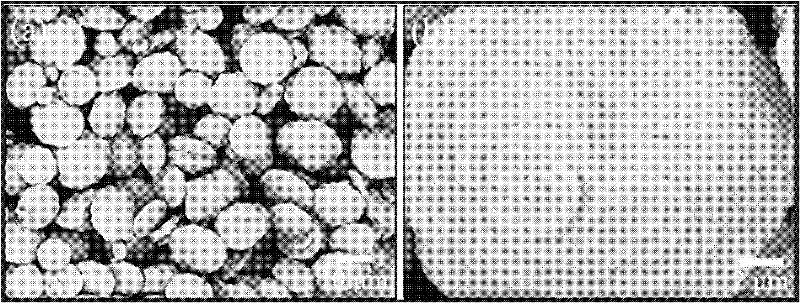

[0037] 1,3-Diamino-2,4,6-trinitrobenzene (DATB, C 6 h 5 o 6 N 5 ) preparation of graded microspheres, the specific steps are:

[0038] 1) Dissolve 0.48g (8mmol) of urea in 50mL of absolute ethanol at room temperature, then add 0.222g (monomer molarity is 2mmol) of surfactant PVP-K30, stir to obtain a yellow solution;

[0039] 2) 0.055g (0.2mmol) precursor 2,3,4,6-tetranitroaniline (TNA, C 6 h 3 o 8 N 5 ) was added to the solution obtained in step 1), stirred at 40°C until TNA was completely dissolved, and a yellow transparent solution was obtained, which was transferred to a stainless steel autoclave lined with polytetrafluoroethylene, and then the autoclave was sealed and placed in a blast Oven, the temperature of the oven is 100°C, the ammonia gas produced by the alcoholysis of urea reacts with TNA, and the reaction time is 9 hours. After the reaction is completed, the solid product is naturally precipitated and separated, and washed alternately with ultrapure water a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com