Foam generator for compressed gas

A foam generator and compressed gas technology, applied in fire rescue and other directions, can solve the problems of less foam consumption, high fire extinguishing intensity, poor foam stability, etc., and achieve the effect of improving mixing capacity, fire extinguishing speed and strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

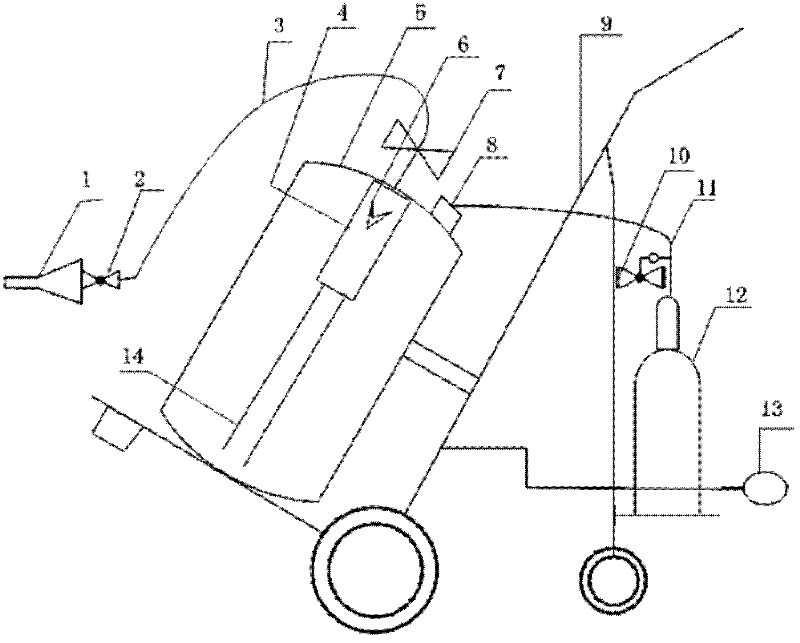

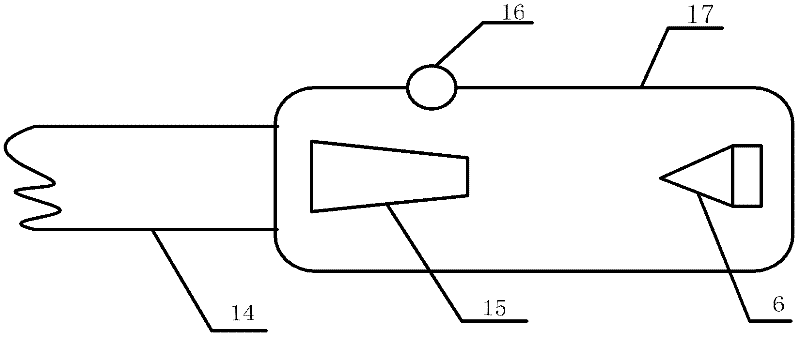

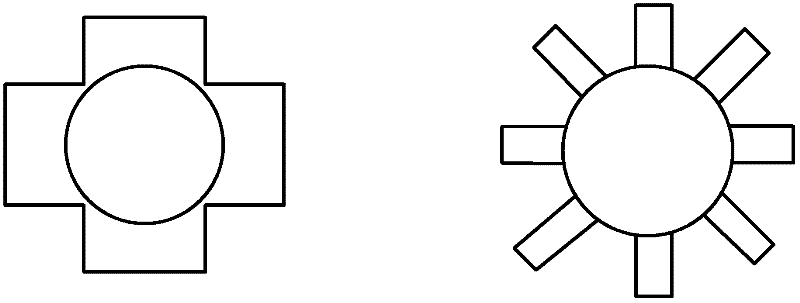

[0030] The present invention is realized through the following technical solutions: According to the principle that the expansion ratio is inversely proportional to the flow rate of the foam fire extinguishing agent premix and proportional to the flow rate of compressed air, a foam generator with uniform foam, steady flow and high kinetic energy is designed and produced. The generator has a nozzle to control the flow of the foam fire extinguishing agent premix and a turbulent to form a mist, and has an air inlet to control the flow of compressed gas. The compressed gas inlet and the fire extinguishing agent inlet are vertical. Among them, the spoiler is a cross or rice-shaped cone or prism with a symmetrical structure. The foam liquid enters the foam generator through the suction pipe and directly impacts the spoiler, and the liquid flow is crushed accordingly to form a mist-like spoiler. At the same time, the gas in the storage tank is injected into the foam generator through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com