Planetary-wheel cantilever-type planting mechanism

A planetary wheel and cantilever technology, applied in the field of planting mechanism, can solve the problems of difficult to guarantee the uprightness of seedlings, easy damage to seedlings by planters, planting in holes, etc., and achieves the effects of compact structure, reduced impact and good planting quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

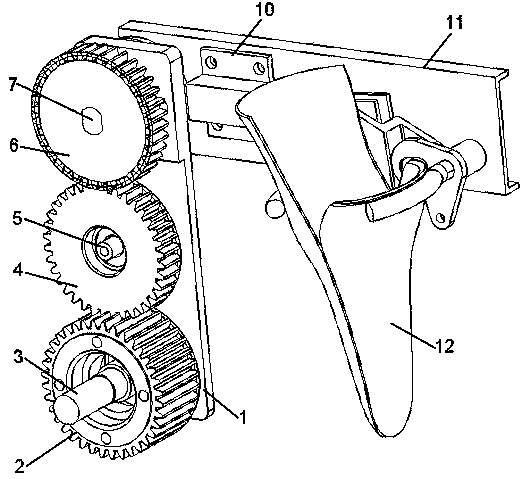

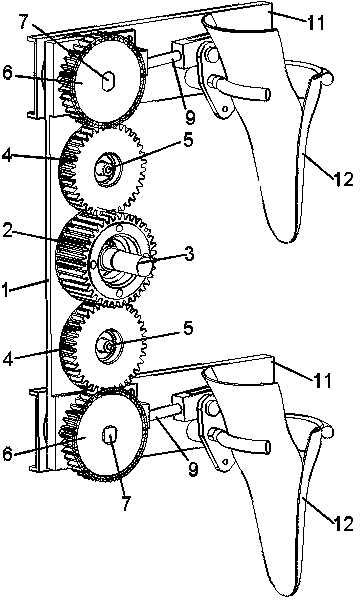

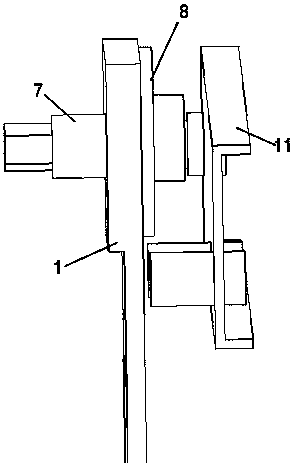

[0024] like figure 1 As shown, the planetary wheel cantilever seedling planting mechanism is mainly composed of a planetary carrier 1, a central wheel 2, an input shaft 3, an intermediate planetary wheel 4, an outer planetary wheel 6, an intermediate planetary wheel shaft 5, an outer planetary wheel shaft 7, a seedling planter cantilever 11 and a duckbill Type seedling planter 12 forms. The planetary carrier 1 is the original moving part of the whole planting mechanism, driven by the input shaft 3, the input shaft 3 passes through the center wheel 2, and is connected with the center wheel 2 to form a rotating pair. Driven by the planet carrier 1, the middle planetary wheel 4 rotates around the fixed center wheel 2, the middle planetary wheel 4 drives the outer planetary wheel 6 to rotate, and the cantilever 11 of the seedling planter rotates around the input shaft 3 on the one hand under the drive of the planetary wheel mechanism. Simultaneously, under the drive of the outer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com