Vacuum liquid filling equipment for soft-package battery

A soft packaging battery and vacuum technology, applied in battery pack parts, circuits, electrical components, etc., can solve the problems of long time for electrolyte to infiltrate cells, low use efficiency of liquid injection pump, unstable product quality, etc. The effect of injection production efficiency, improvement of injection accuracy and stability, and shortening of infiltration time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

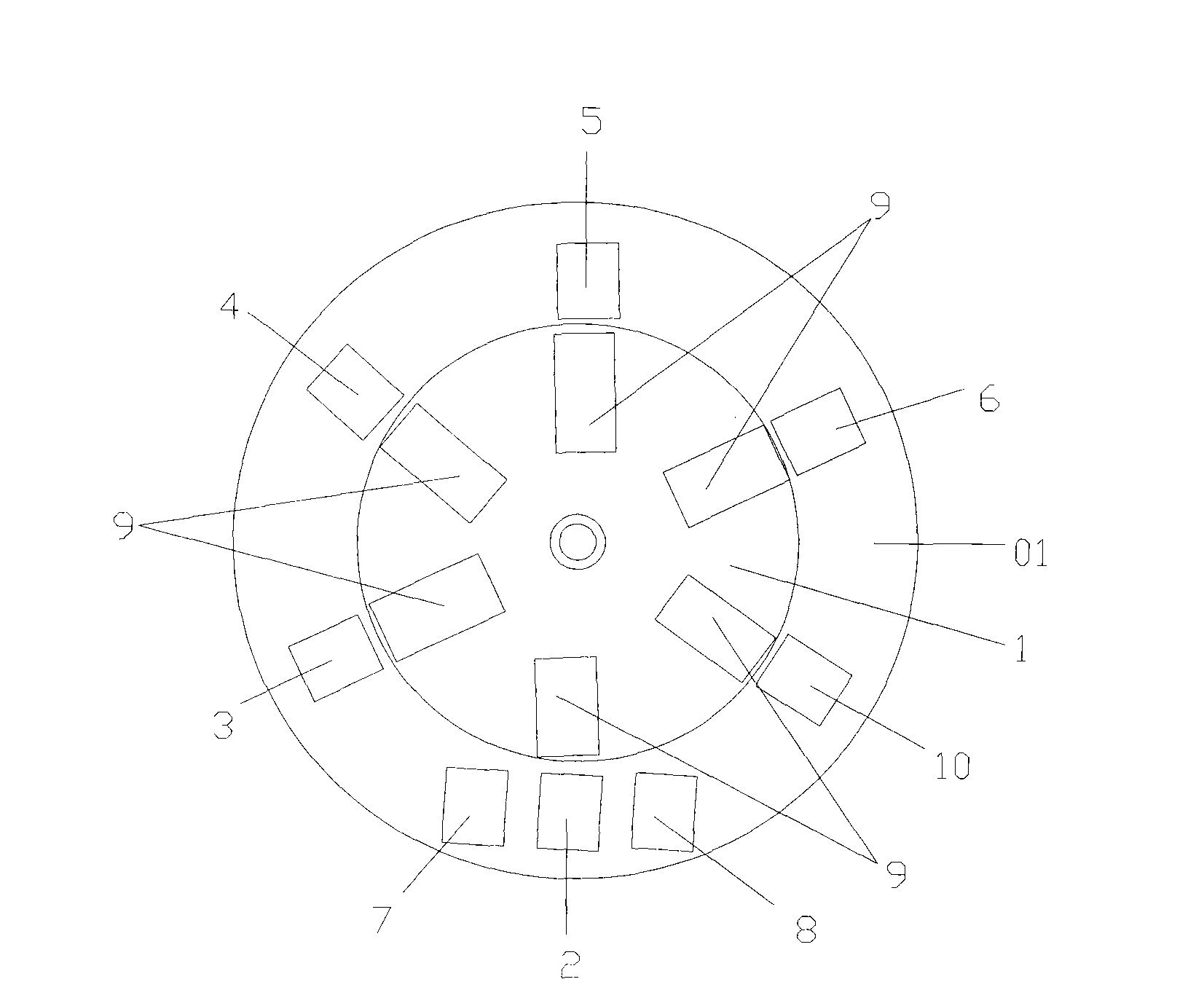

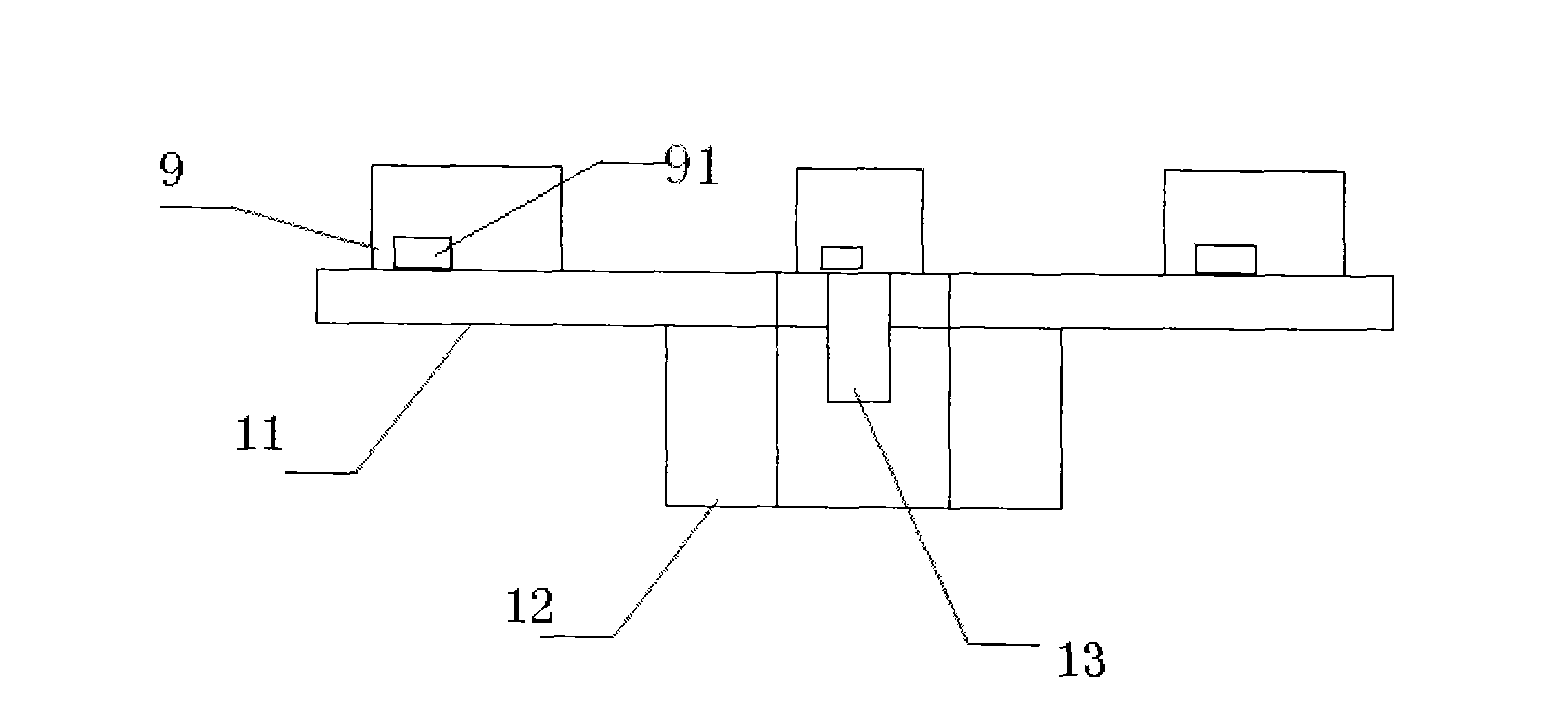

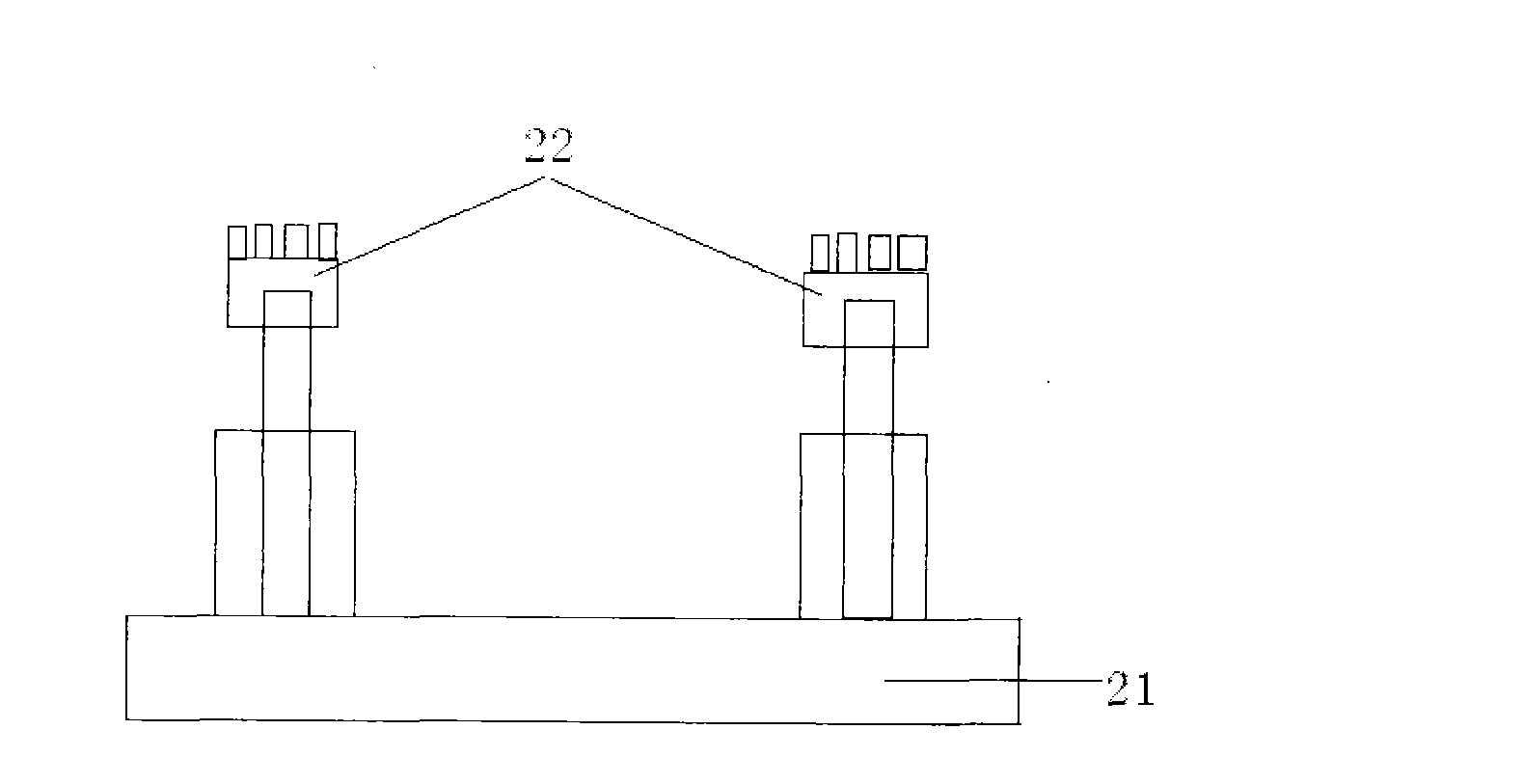

[0029] Such as figure 1 and figure 2 As shown, the flexible packaging battery vacuum liquid injection equipment of the present invention includes a frame 01 and a multi-station turntable 1 arranged on the frame 01, and any station of the multi-station turntable 1 is equipped with a drawer type A sealed box 9, the drawer-type sealed box 9 is fixed with a battery fixing fixture 91, and the periphery of the multi-station turntable 1 is fixed in turn with one-to-one correspondence with each station of the multi-station turntable 1. The battery loading and unloading unit 2, the suction battery bag unit 3, the vacuum unit 4, the liquid injection unit 5 and the sealing unit 6, and the two sides of the battery loading and unloading unit 2 are respectively fixedly connected with a weighing unit 7 and a weighing unit before liquid injection. A weighing unit 8 after liquid injection, a backup unit 10 is provided between the sealing unit 6 and the battery loading and unloading unit 2 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com