Power generation method adopting ionic thermal motion principle and graphene battery manufactured by power generation method

A technology of ion heat and graphene, applied in thermoelectric devices, thermoelectric device components, circuits, etc., can solve the problems of human body and environment hazards, battery safety hazards, and electric charging, etc., to reduce safety hazards and performance attenuation Small, avoiding the effect of frequent maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

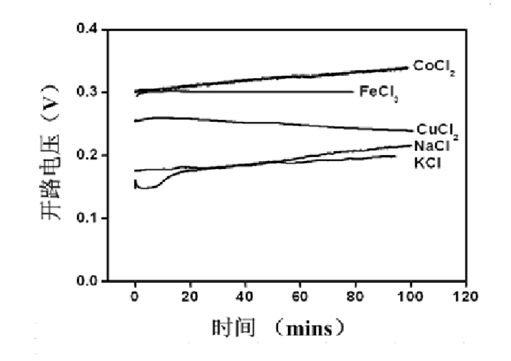

[0070] Silver and gold electrodes were used to form the positive and negative electrodes of the device, respectively. First, the graphene film is transferred to a glass substrate, figure 1 3 is a glass substrate, and 4 is a graphene film, which are formed by evaporation figure 1 The two non-contact electrodes are the first electrode 5 and the second electrode 6. figure 1 Among them, the first electrode 5 is an electrode using gold evaporation, figure 1 The second electrode 6 is an electrode produced by silver vapor deposition. Secondly, use conductive glue or soldering to fix the two wires 7 on the electrodes. Then dip it into ionic salt solution 2, as in figure 2 shown. CoCl 2 , FeCl 3 , CuCl 2 , NaCl, KCl, to get the effect as image 3 shown. Put the container housing 1 containing the ionic salt solution 2 and the device into an environment with a certain temperature, and obtain the open circuit voltage of the ferric chloride solution at different temperatures...

Embodiment 2

[0072] The two electrodes (5, 6) were replaced by silver-containing and nickel-containing conductive materials, and the rest of the operations were as in Example 1.

Embodiment 3

[0074] The two electrodes (5, 6) were replaced by graphite-containing and nickel-containing conductive materials, and the rest of the operations were as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com