Ceramic discharge container and metal halide lamp

A metal halide and discharge vessel technology, which is applied in the direction of discharge lamps, gas discharge lamps, gas discharge lamp components, etc., can solve the problem of affecting the luminous flux maintenance rate and ignition life of the light source, large tube wall load, and small tube inner diameter To achieve excellent luminous efficiency and color reproduction, improve reliability and safety, and eliminate tube wall degeneration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

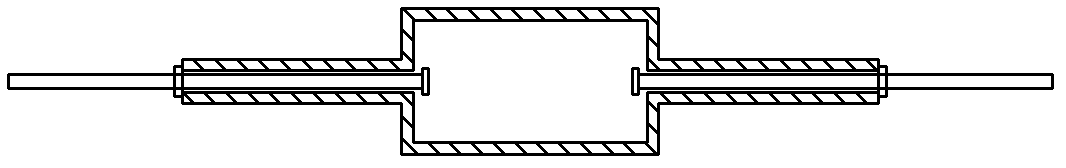

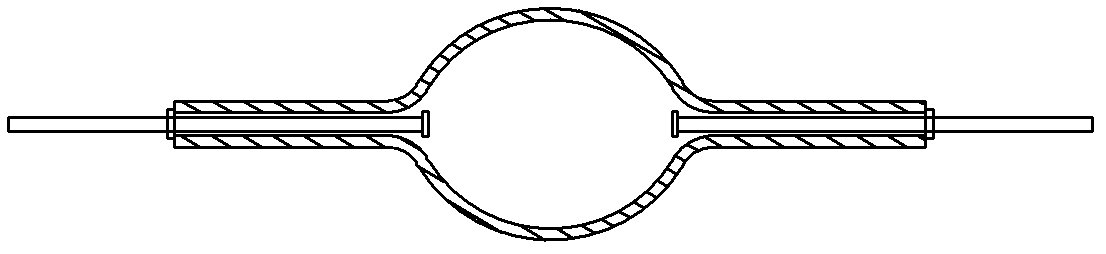

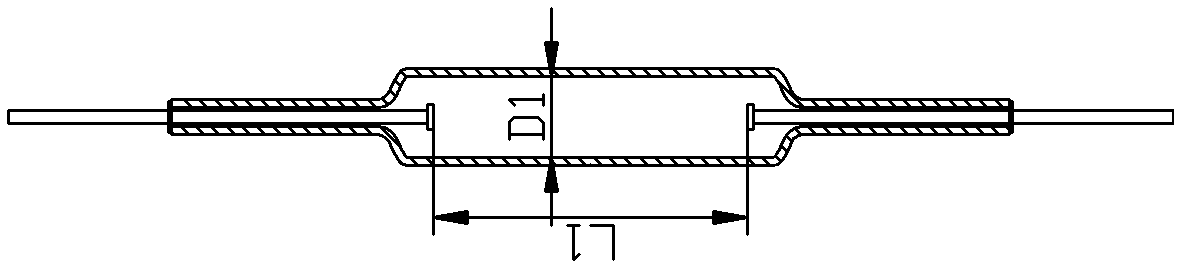

[0024] Such as Figure 4 As shown, a kind of ceramic discharge vessel of the present invention comprises a discharge main pipe and two capillaries 2 connected to two ends of the discharge main pipe. An electrode is respectively arranged in the two capillaries, and the discharge main pipe includes a bulging section 3 in the middle and two ends of the discharge main pipe Cylindrical section 1, bulging section 3 is smoothly connected with cylindrical section 1, the bottom of bulging section 3 is flush with the cylindrical section, and the top of bulging section 3 is higher than the top of cylindrical section 1. There is an upwardly raised space in the middle of the discharge chamber 4 formed in the discharge main pipe, so that the discharge chamber is an asymmetrical ceramic chamber, which can effectively prevent the temperature of the central p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com