DCS (Distributed Control System) based integrated-control system of coal-fired power plant

A technology for control systems and coal-fired power plants, applied in the direction of electrical program control, comprehensive factory control, etc., can solve problems such as difficulty in project implementation, repeated equipment configuration, waste of resources, etc., reduce training costs and time, and improve large-scale networking capabilities , The effect of reducing operating production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below in conjunction with specific embodiments.

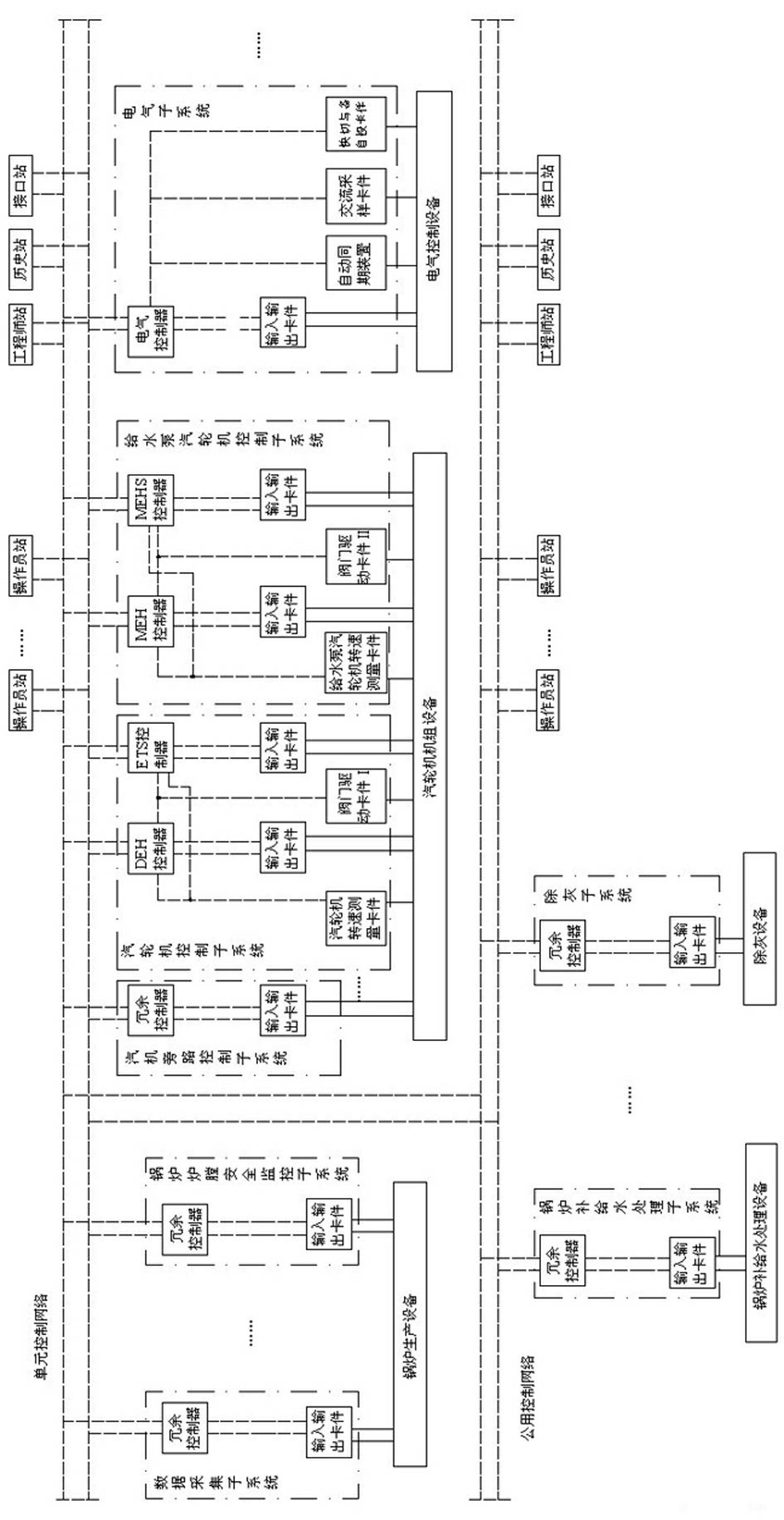

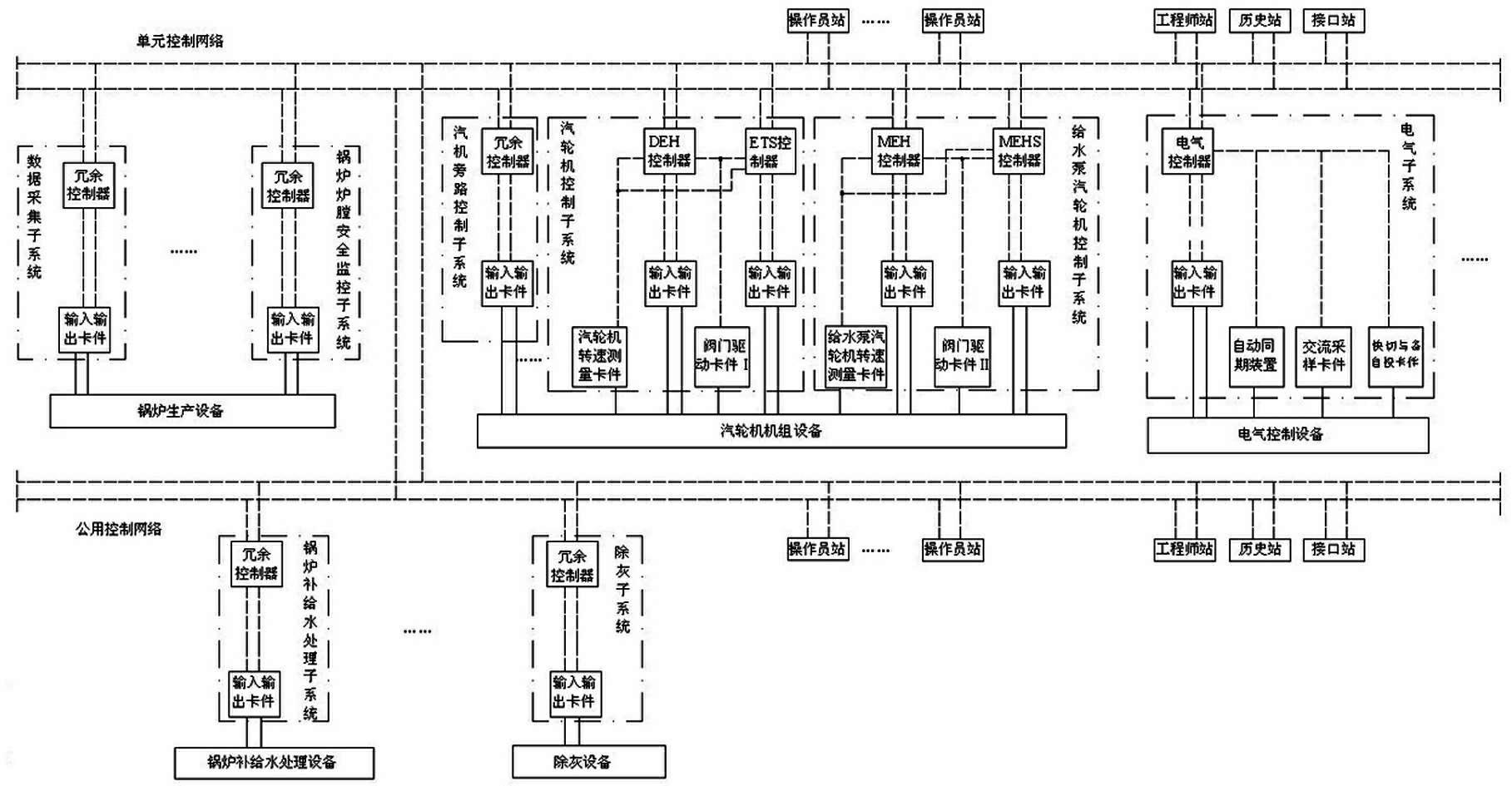

[0020] Coal-fired power plant integrated control system based on DCS. This control system is based on the principle of DCS decentralized control, including the control system and human-computer interaction equipment. The control system communicates with the operator through the human-computer interaction equipment.

[0021] The control system includes the main workshop control system and the auxiliary workshop control system.

[0022] The main plant control system mainly includes a unit control system and a public control system composed of related independent control subsystems, among which the independent subsystems include data acquisition subsystems, analog control subsystems and sequence control subsystems, boiler furnace safety monitoring subsystems, Steam turbine control subsystem, feed water pump steam turbine control subsystem, steam turbine bypass contro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com