Device and method for automatic calibrating in water treatment analog data collecting system

A technology of analog data and acquisition system, which is applied in the field of automatic calibration device of water treatment analog data acquisition system, can solve the problems of large calibration method error, complicated operation, can not meet industrial standards, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

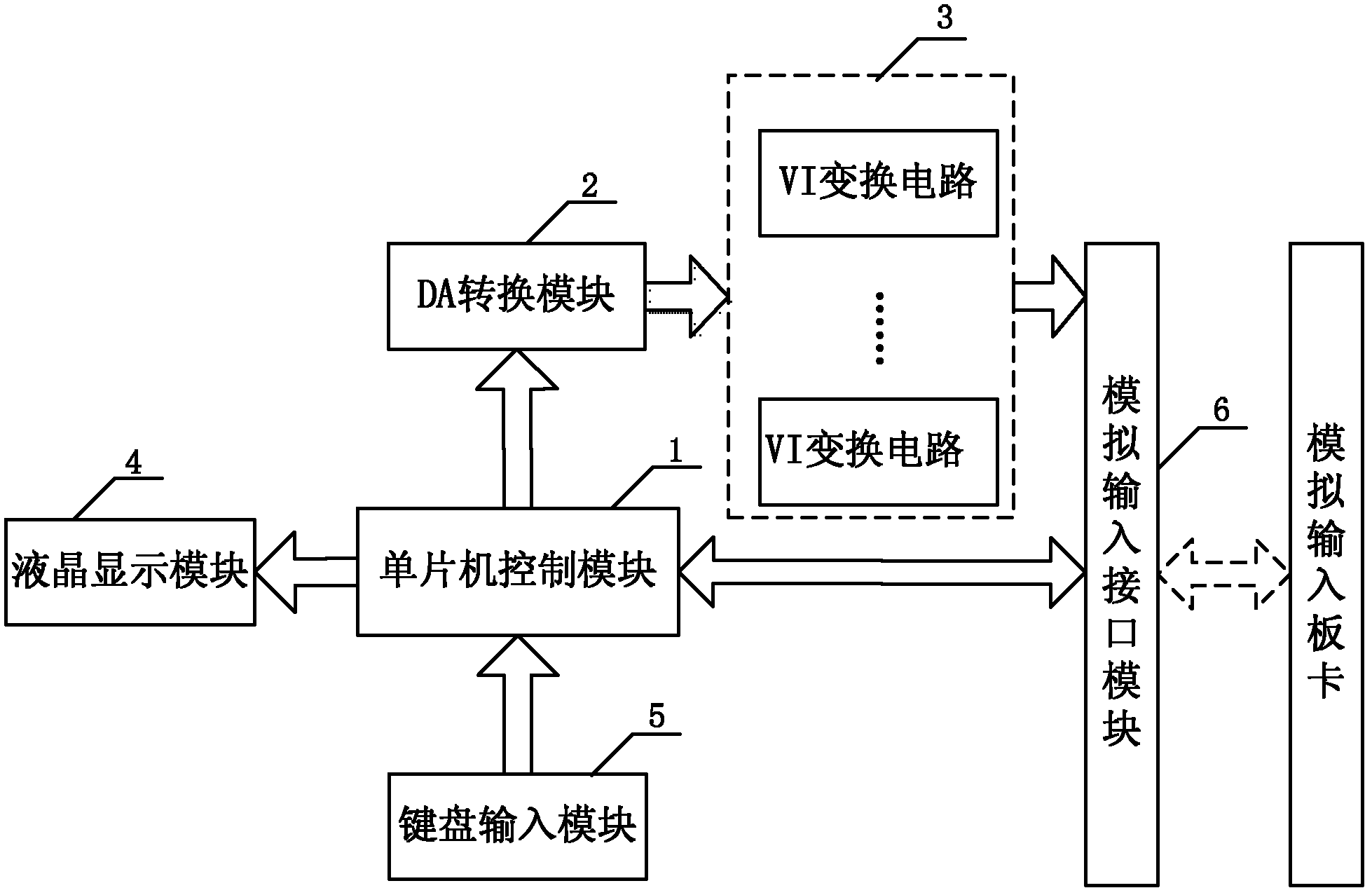

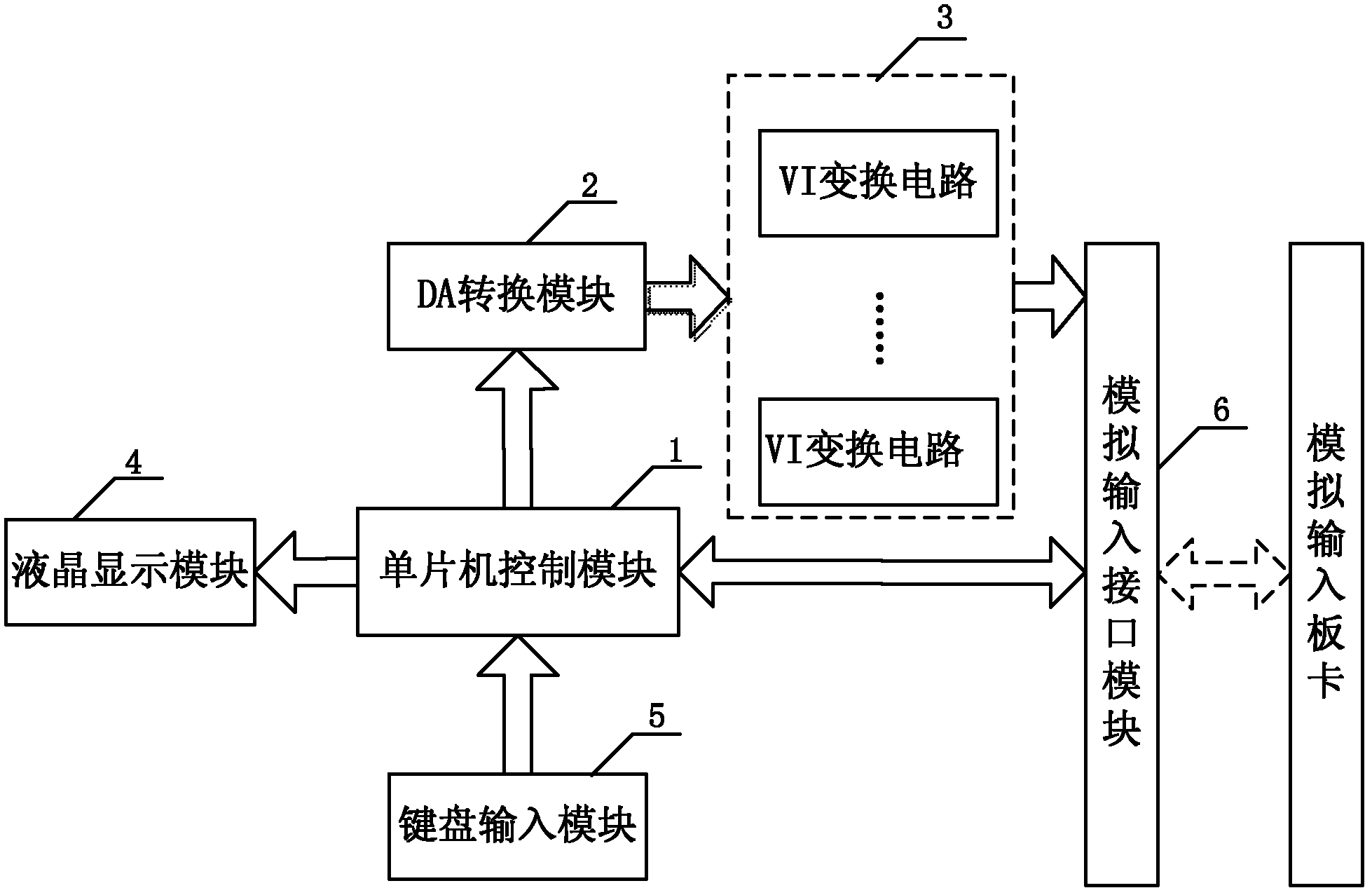

[0017] Specific implementation mode one: the following combination figure 1 Describe this embodiment, the water treatment analog data acquisition system automatic calibration device described in this embodiment, it comprises single-chip microcomputer control module 1, DA conversion module 2, VI conversion module 3, liquid crystal display module 4, keyboard input module 5 and analog input interface Module 6,

[0018] The output terminal of the keyboard input module 5 is connected with the key information input terminal of the single-chip microcomputer control module 1, and the display output terminal of the single-chip microcomputer control module 1 is connected with the input terminal of the liquid crystal display module 4,

[0019] The standard current signal control output terminal of the single-chip microcomputer control module 1 is connected with the digital signal input terminal of the DA conversion module 2, and the analog signal output terminal of the DA conversion modu...

specific Embodiment approach 2

[0022] Embodiment 2: This embodiment further explains Embodiment 1. The single-chip microcomputer control module 1 is realized by an enhanced 51 single-chip microcomputer STC12C5A60S2.

specific Embodiment approach 3

[0023] Embodiment 3: This embodiment further describes Embodiment 1. The DA conversion module 2 is realized by a 14-bit or 16-bit DA chip. This embodiment provides a specific model: Maxim's 14-bit DA chip MAX5170.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com