Asymmetric capacitance and resistance increasing and injecting method of zero-sequence current

An asymmetric capacitor and zero-sequence current technology, which is applied in the direction of measuring current/voltage, measuring electrical variables, instruments, etc., can solve the problems of small injected energy, difficult line selection and positioning, etc., so as to increase the current amplitude and avoid the effect of shunting Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

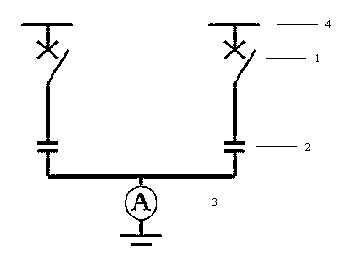

[0019] See figure 1 , the asymmetric capacitance injection method is to connect the upper terminal of the high-voltage vacuum contactor 1 with the three-phase power bus 4 of the substation, and connect the lower terminal of the high-voltage vacuum contactor 1 with the upper terminal of the high-voltage capacitor 2 of the non-fault phase, The lower terminals of the non-fault phase high-voltage capacitor 2 are connected to each other and then connected to the upper terminal of the ammeter 3, and the lower terminal of the ammeter 3 is connected to the ground. Will figure 1 The non-fault phase high-voltage capacitor 2 is connected to the three-phase power bus 4 through the high-voltage vacuum contactor 1, for example, connected to the 10 KV three-phase power bus, so that the injected current flows through the non-fault phase high-voltage capacitor 2 under the action of the power supply voltage and the transition resistance 5 of the grounding point, by adjusting the size of the ...

Embodiment 2

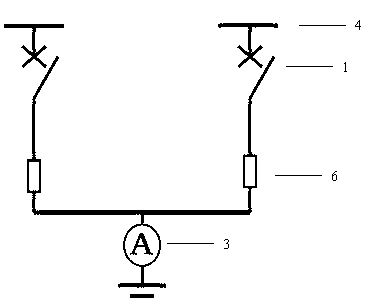

[0021] See figure 2 , the asymmetric resistance injection method is to connect the upper terminal of the high-voltage vacuum contactor 1 with the three-phase power bus 4 of the substation, and connect the lower terminal of the high-voltage vacuum contactor 1 to the upper terminal of the non-faulty phase resistance 6. The lower terminals of the faulty phase resistance 6 are connected to each other and then connected to the upper terminal of the ammeter 3, and the lower terminal of the ammeter 3 is connected to the ground. Will figure 2 The non-fault phase resistor 6 is connected to the three-phase power bus 4 through the high-voltage vacuum contactor 1, for example, connected to the 10KV three-phase power bus, so that the injection current flows through the non-fault phase resistor 6 and the grounding point under the action of the power supply voltage The transition resistance 5 is adjusted by adjusting the size of the non-fault phase resistance 6 . The purpose of increasing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com