Process for assembling heat contact rod end part of billet hold-out rod

An assembly process and hot-touch technology, applied in the direction of manufacturing tools, presses, etc., can solve problems such as inconsistent gaps, affecting the normal operation of the head frame and carriage, and achieve the effect that the gaps are basically consistent and the up and down operations are smooth and smooth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

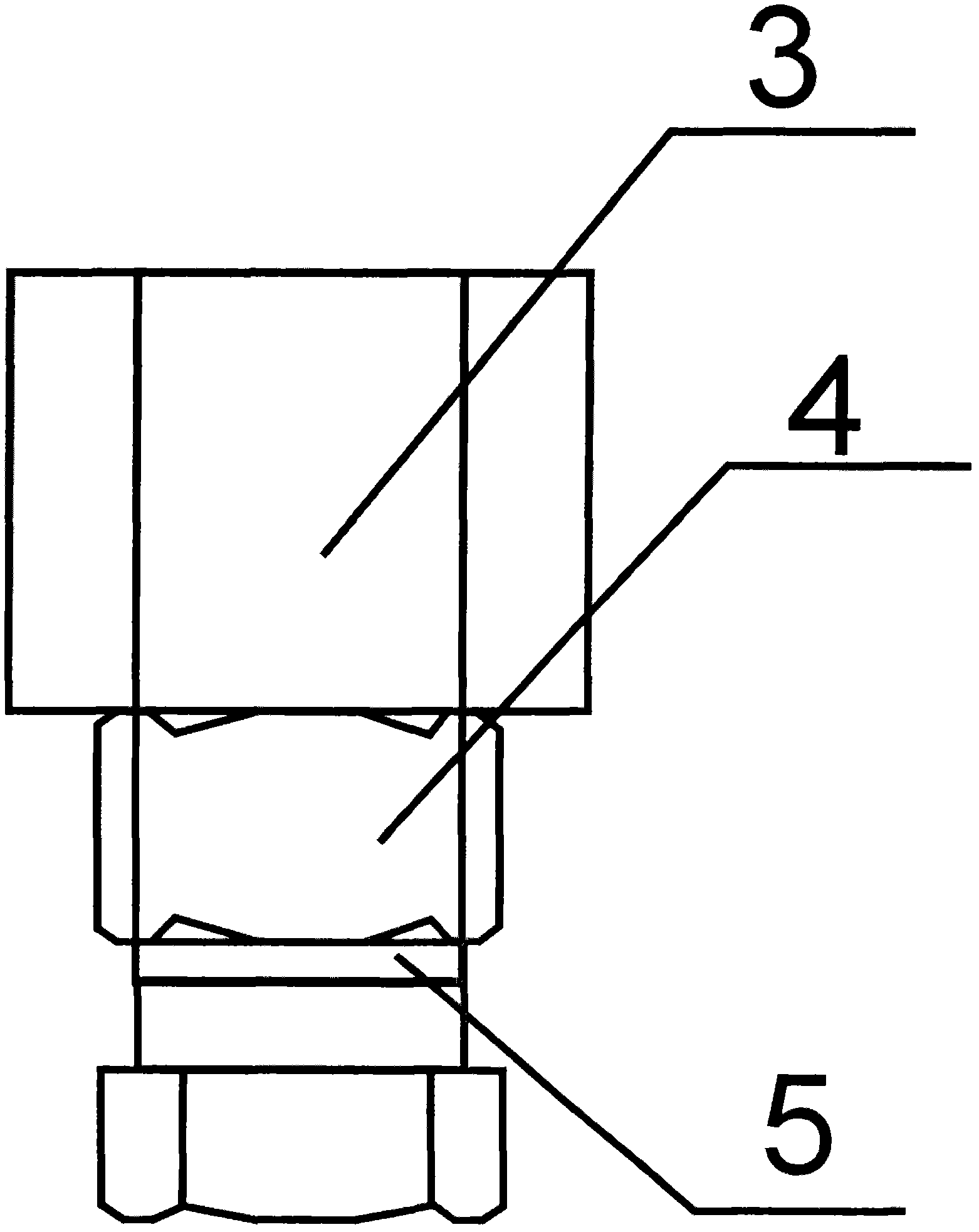

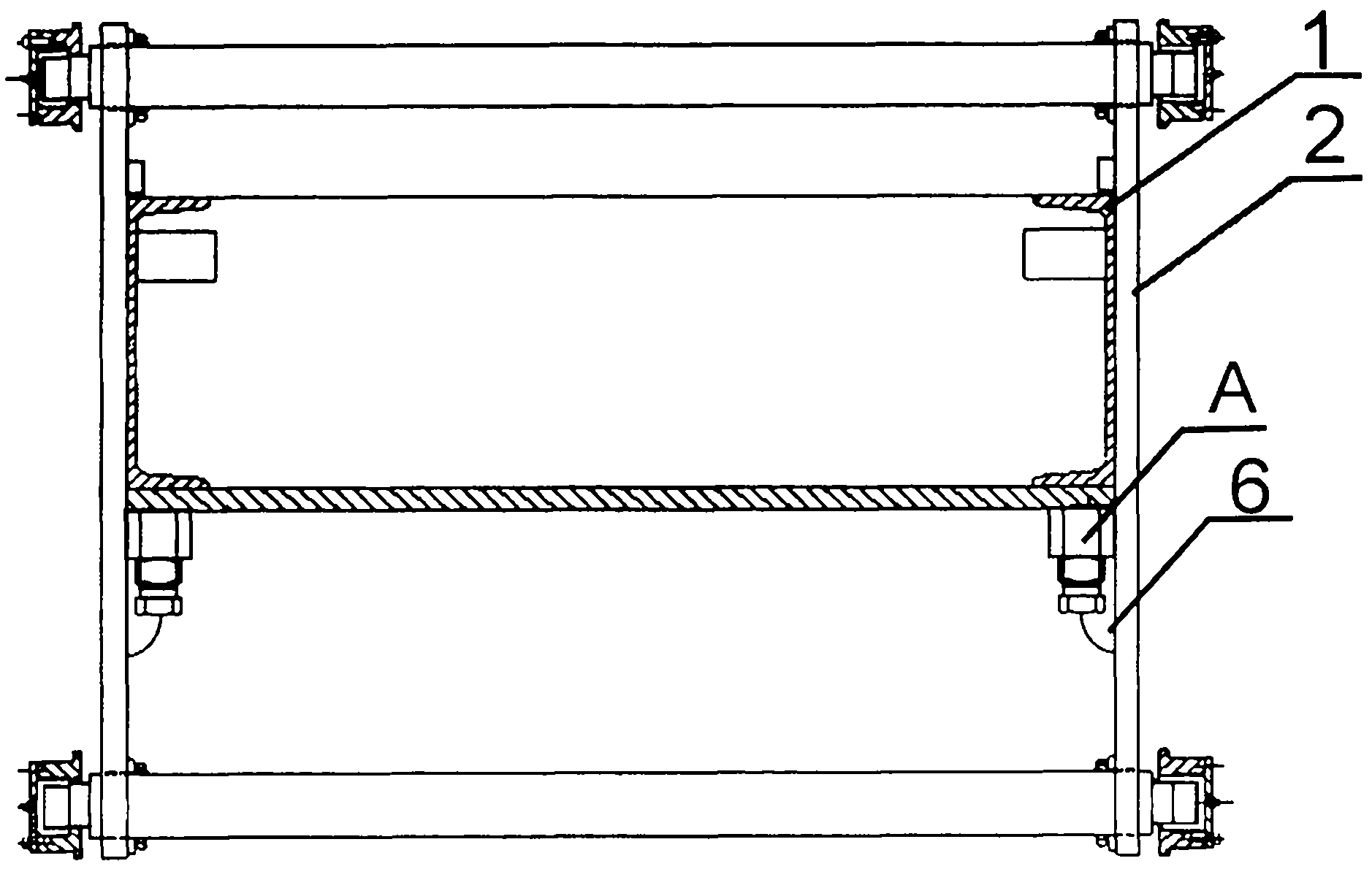

[0008] combine figure 2 Shown: First, widen the steel plate on the lower side of the preset guide groove on the upper part of the slide frame (2), and then uniformly tap 4-5 threaded holes on the steel plate; when the head frame (1) and the slide frame (2) ) for assembly, use the hexagonal bolt (3) to screw into the top frame from bottom to top, the hexagonal bolt (3) penetrates the bottom plate and the steel plate of the headframe (1), and the tip is tightened with a hexagonal nut. Tap 4-5 threaded holes evenly on the steel plate on the lower side of the guide groove of the carriage. After the head frame and the carriage are assembled correctly, use bolts from bottom to top to achieve the purpose of fastening assembly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com