Catalyst carrier composite for resisting high temperature sintering and preparation method thereof

A technology of catalyst carrier and composite material, applied in the direction of catalyst carrier, chemical instrument and method, physical/chemical process catalyst, etc., can solve the problems of limitation, thermal shock resistance, poor mechanical strength at high temperature and chemical stability, etc. The effect of stability, excellent high temperature sintering resistance, and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

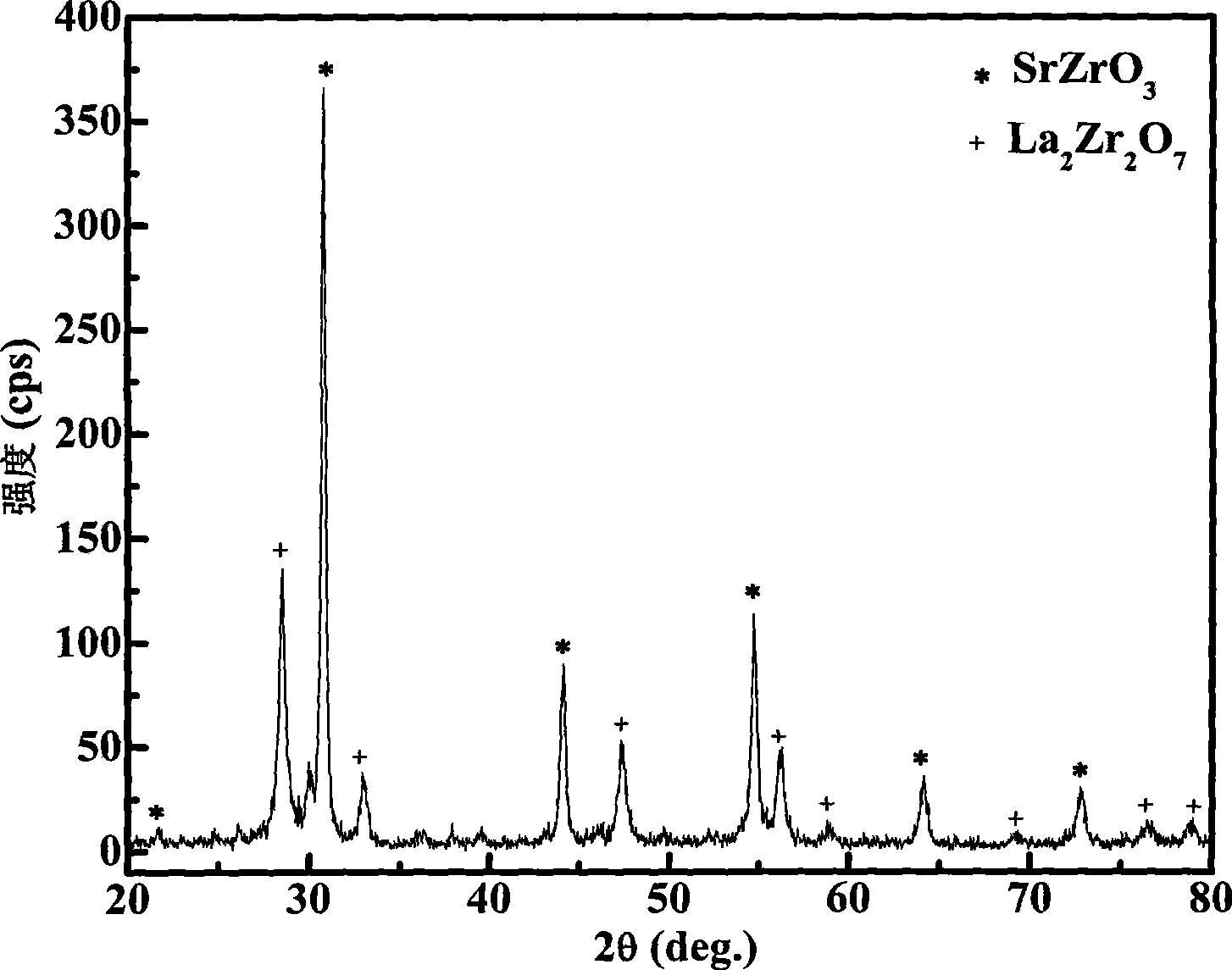

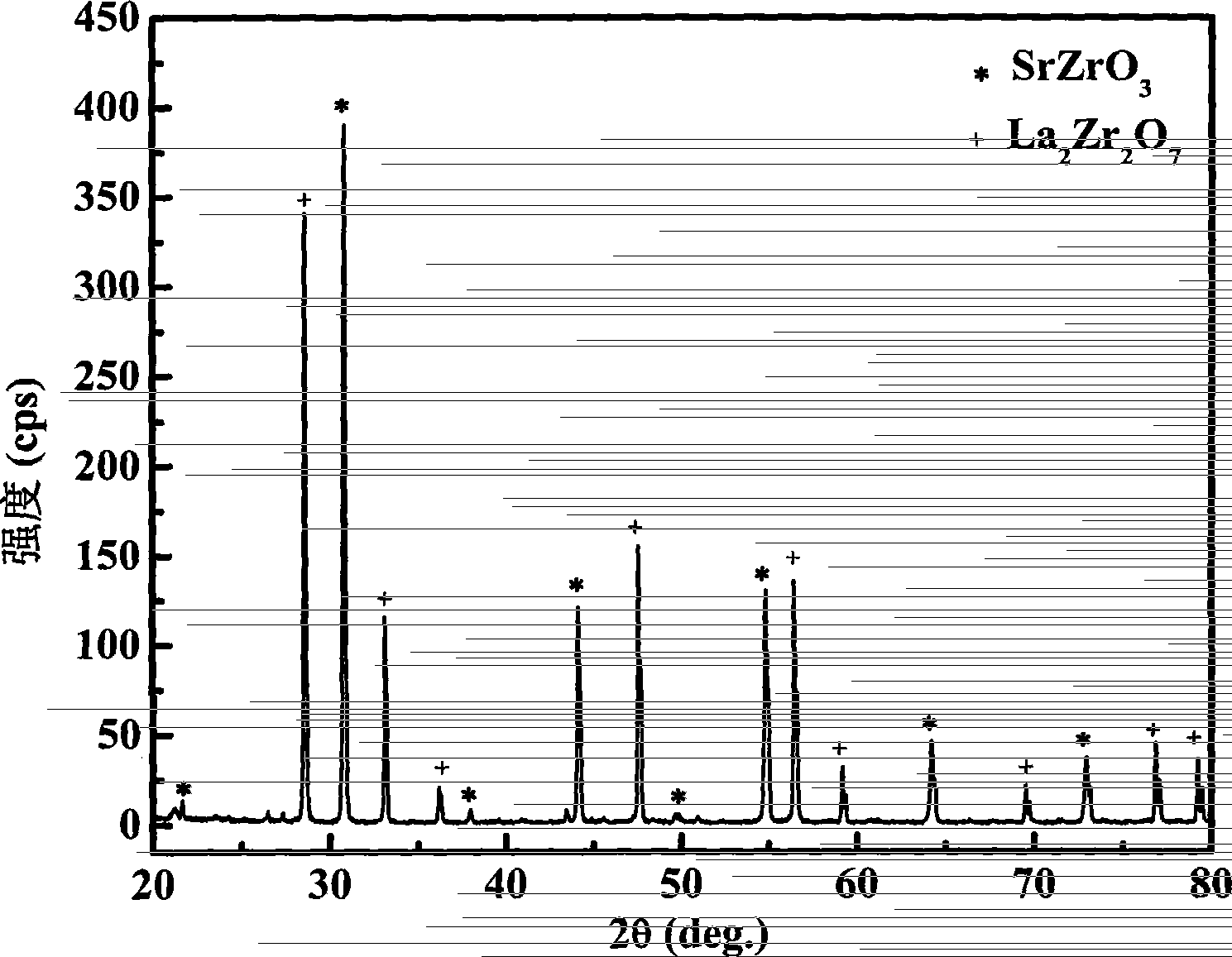

[0019] 0.85g (4.0×10 -3 mol)Sr(NO 3 ) 2 , 2.138g (8×10 -3 mol)ZrO(NO 3 ) 2 2H 2 O with 1.73g (4.0×10 -3 mol)La(NO 3 ) 3 ·6H 2 O was dissolved in deionized water to obtain a mixed solution (1); 3 g of PVP was dissolved in absolute ethanol and stirred with electromagnetic stirring for 1 h to obtain a solution (2); the solutions (1) and (2) were mixed and stirred with electromagnetic stirring for 3 h The solution (3) was obtained; the mixed solution (3) was evaporated to dryness at 80°C in a water bath, and then calcined at 1000°C for 6h to obtain the powder (4), that is, the catalyst carrier composite material powder Sr 0.5 La 0.5 ZrO 3.25 . figure 1 is the Sr after 6h after calcination at 1000℃ 0.5 La 0.5 ZrO 3.25 The XRD pattern of the powder, indicating the generation of SrZrO 3 with La 2 Zr 2 o 7 two-phase composites. The powder was calcined at high temperature to test its high temperature sintering resistance and phase stability. Among them, the specifi...

Embodiment 2

[0021] 1.016g (4.8×10 -3 mol)Sr(NO 3 ) 2 , 2.138g (8×10 -3 mol)ZrO(NO 3 ) 2 2H 2 O with 1.442g (3.2×10 -3 mol)Sm(NO 3 ) 3 ·6H 2 O was dissolved in deionized water to prepare a mixed solution (1); 4g of PVP was dissolved in absolute ethanol and stirred with electromagnetic stirring for 2h to prepare a solution (2); the solutions (1) and (2) were mixed and stirred with electromagnetic stirring for 4h The solution (3) was prepared; the mixed solution (3) was evaporated to dryness at 70°C in a water bath, and then calcined at 1000°C for 8h to obtain the powder (4), that is, the catalyst carrier composite material powder Sr 0.6 SM 0.4 ZrO 3.2 . After the powder was calcined at 1000°C and 1400°C for 12 hours, the specific surface area reached 10.85m 2 g -1 and 6.27m 2 g -1 . After the powder was calcined at 1400°C for 50h, the SrZrO 3 with La 2 Zr 2 o 7 two-phase composition.

Embodiment 3

[0023] 0.508g (2.4×10 -3 mol)Sr(NO 3 ) 2 , 2.138g (8×10 -3 mol)ZrO(NO 3 ) 2 2H 2 O with 2.498g (5.6×10 -3 mol)Eu(NO 3 ) 3 ·6H 2 O was dissolved in deionized water to make a mixed solution (1); 5g of PVP was dissolved in absolute ethanol and stirred with electromagnetic stirring for 3h to make a solution (2); the solutions (1) and (2) were mixed and stirred with electromagnetic stirring for 4h The solution (3) is prepared; the mixed solution (3) is evaporated to dryness in a water bath at 80°C, and then calcined at 1000°C for 10 hours to obtain the powder (4), that is, the catalyst carrier composite material powder Sr 0.3 Eu 0.7 ZrO 3.35 . After the powder was calcined at 1000°C and 1400°C for 12 hours, the specific surface area reached 10.15m 2 g -1 and 5.93m 2 g -1 . After the powder was calcined at 1400°C for 50h, the SrZrO 3 with La 2 Zr 2 o 7 two-phase composition.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com