Silica gel regenerator and regeneration method

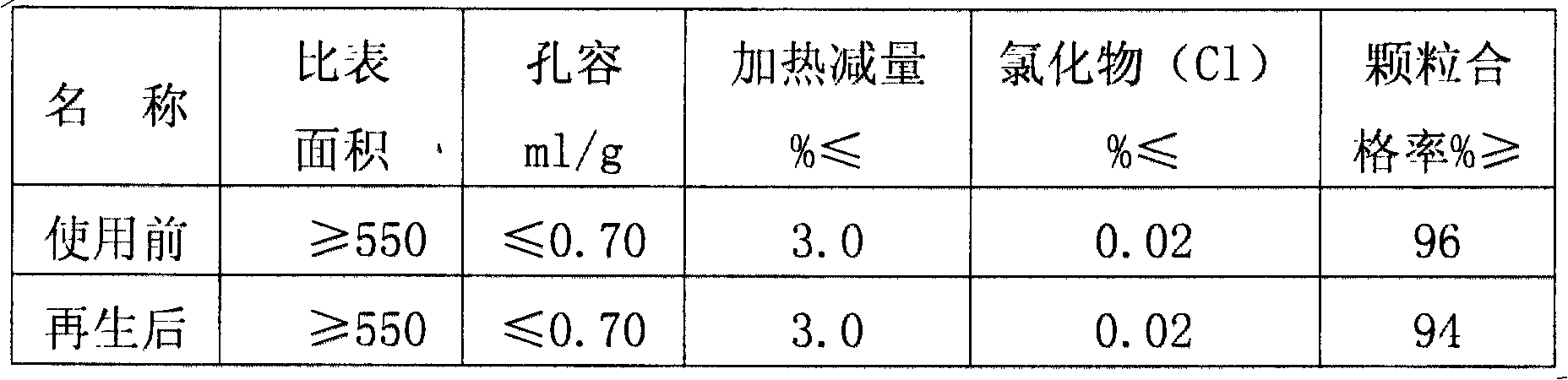

A silica gel regeneration furnace, silica gel technology, applied in separation methods, filter regeneration, silicon compounds, etc., can solve the problems of colloidal crystal deformation, difficult to grasp the fuel heating method, difficult to grasp the method of decolorizing silica gel activation and regeneration, and difficult to grasp the process conditions, Achieve the effect of solving technical problems and ensuring the effect of regeneration and activation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Such as figure 1 , 2 A silica gel regeneration furnace shown includes a vertical furnace body 10 for filling silica gel. In order to be able to charge and discharge materials, any existing method or equivalent means can be used to set the feeding and discharging mechanism on the furnace body 10. structure. The improvement is: the upper part of the furnace body 10 is provided with a hot air device that provides hot air, and the hot air device can also be any existing embodiment or structure, such as an electrically heated air heater, etc., or use a fan to blow fuel such as firewood or pure gas The hot air blowing conveying structure. The lower part of the furnace body 10 is provided with an exhaust mechanism, such as an exhaust outlet or an exhaust air duct. As long as the hot air flow provided by the hot air device is formed as a whole, the structure is exhausted from the furnace body 10 through the exhaust mechanism from top to bottom in the inner cavity of the furn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com