Green tea processing technology being capable of keeping green and increasing fragrance

A processing technology, green tea technology, applied in the direction of tea treatment before extraction, etc., can solve the problems of aroma loss, up to several minutes or ten minutes, zooming and blurring of tea surface, etc., to improve the grade of tea, increase economic benefits, fragrance invariant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A kind of green tea processing technology that keeps green and improves fragrance, comprises the following steps:

[0034] Step 1. Spread the fresh leaves

[0035] Spread the fresh leaves for 4 hours, under the premise of maintaining the freshness, the substances in the fresh leaves can be fully transformed, so as to increase the freshness of the tea leaves;

[0036] Step two, finish

[0037] Utilize the drum-type continuous greening machine for greening, the temperature of the cylinder wall of the drum-type continuous greening machine is controlled at 300 degrees Celsius, and the time is controlled at 1 minute; the water content of the tea leaves after greening is controlled at 58%;

[0038] The standard is: emerald green color, soft leaves, elastic balls when kneaded by hands, continuous folding of stems, slight fragrance, no burnt edges, bursting spots, and complete buds and leaves.

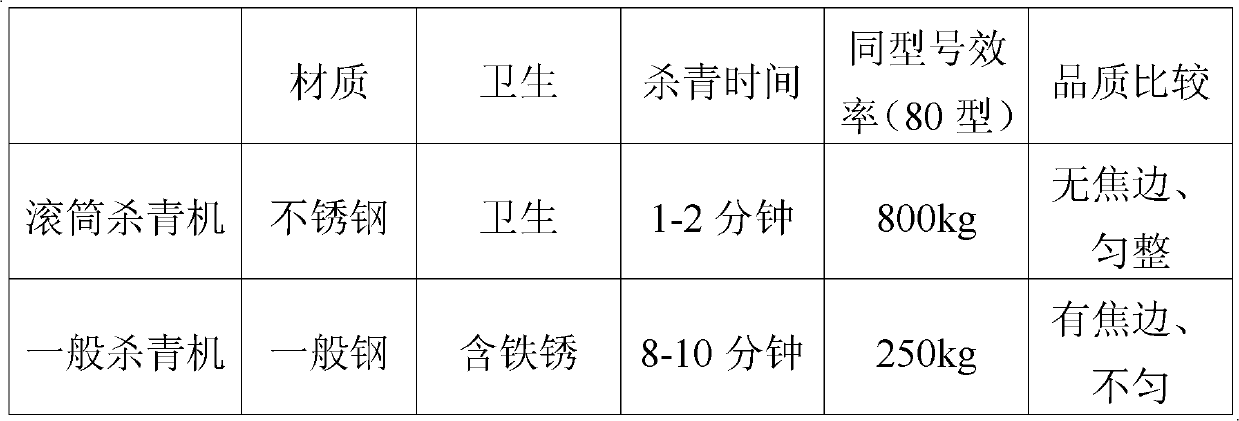

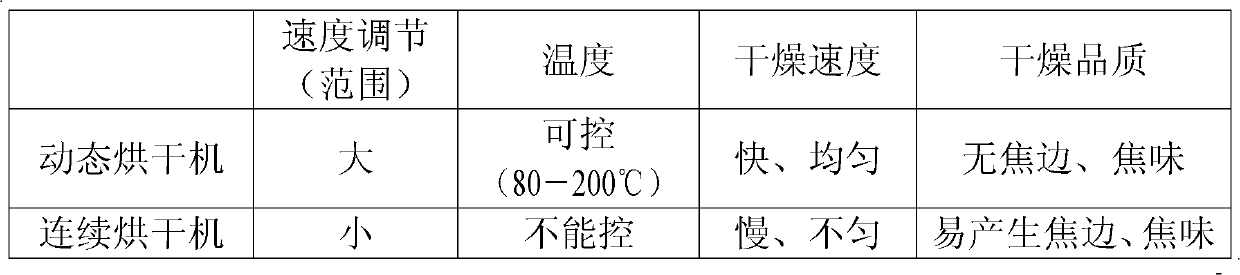

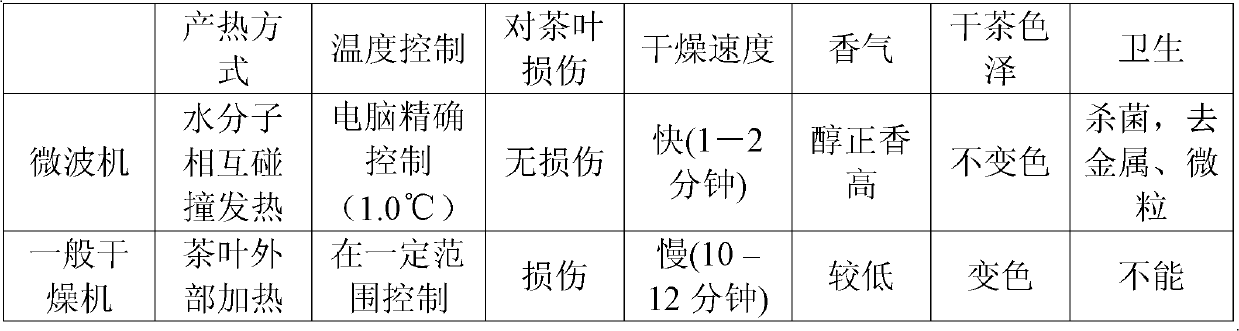

[0039] Attachment: The difference between the drum type continuous greening machi...

Embodiment 2

[0064] A kind of green tea processing technology that keeps green and improves fragrance, comprises the following steps:

[0065] Step 1. Spread the fresh leaves

[0066] Spread the fresh leaves for 5 hours, under the premise of maintaining the freshness, the substances in the fresh leaves can be fully transformed, so as to increase the freshness of the tea leaves;

[0067] Step two, finish

[0068] Utilize the drum-type continuous greening machine for greening, the temperature of the cylinder wall of the drum-type continuous greening machine is controlled within 310 degrees Celsius, and the time is controlled for 1.5 minutes; the water content of the tea leaves after greening is controlled at 59%;

[0069] Step three, kneading

[0070] Use mechanical equipment to process the shape of tea leaves, and use stainless steel electric heaters to control the temperature within 270 degrees Celsius;

[0071] The tea leaves in this embodiment are young leaves with leaves, and the you...

Embodiment 3

[0080] A kind of green tea processing technology that keeps green and improves fragrance, comprises the following steps:

[0081] Step 1. Spread the fresh leaves

[0082] Spread the fresh leaves for 6 hours, under the premise of maintaining the freshness, the substances in the fresh leaves can be fully transformed, so as to increase the freshness of the tea leaves;

[0083] Step two, finish

[0084] Utilize the drum-type continuous greening machine for greening, the temperature of the drum wall of the drum-type continuous greening machine is controlled at 320 degrees Celsius, and the time is controlled for 2 minutes; the water content of the tea leaves after greening is controlled within 60%;

[0085] Step three, kneading

[0086] Use mechanical equipment to process the shape of tea leaves, and use stainless steel electric heaters, and the temperature is controlled at 280 degrees Celsius;

[0087] The tealeaves in the present embodiment is a single bud, and a large-scale re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com