Ammonium sulphate-limestone method for desulphurization of flue gas

A limestone and flue gas technology, applied in separation methods, chemical instruments and methods, dispersed particle separation, etc., can solve the problems of high operating cost, gypsum can not reach the application grade, and it is difficult to further improve desulfurization efficiency, and achieve large operation. Flexibility, improve the comprehensive utilization space of by-products, and stabilize the pH value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

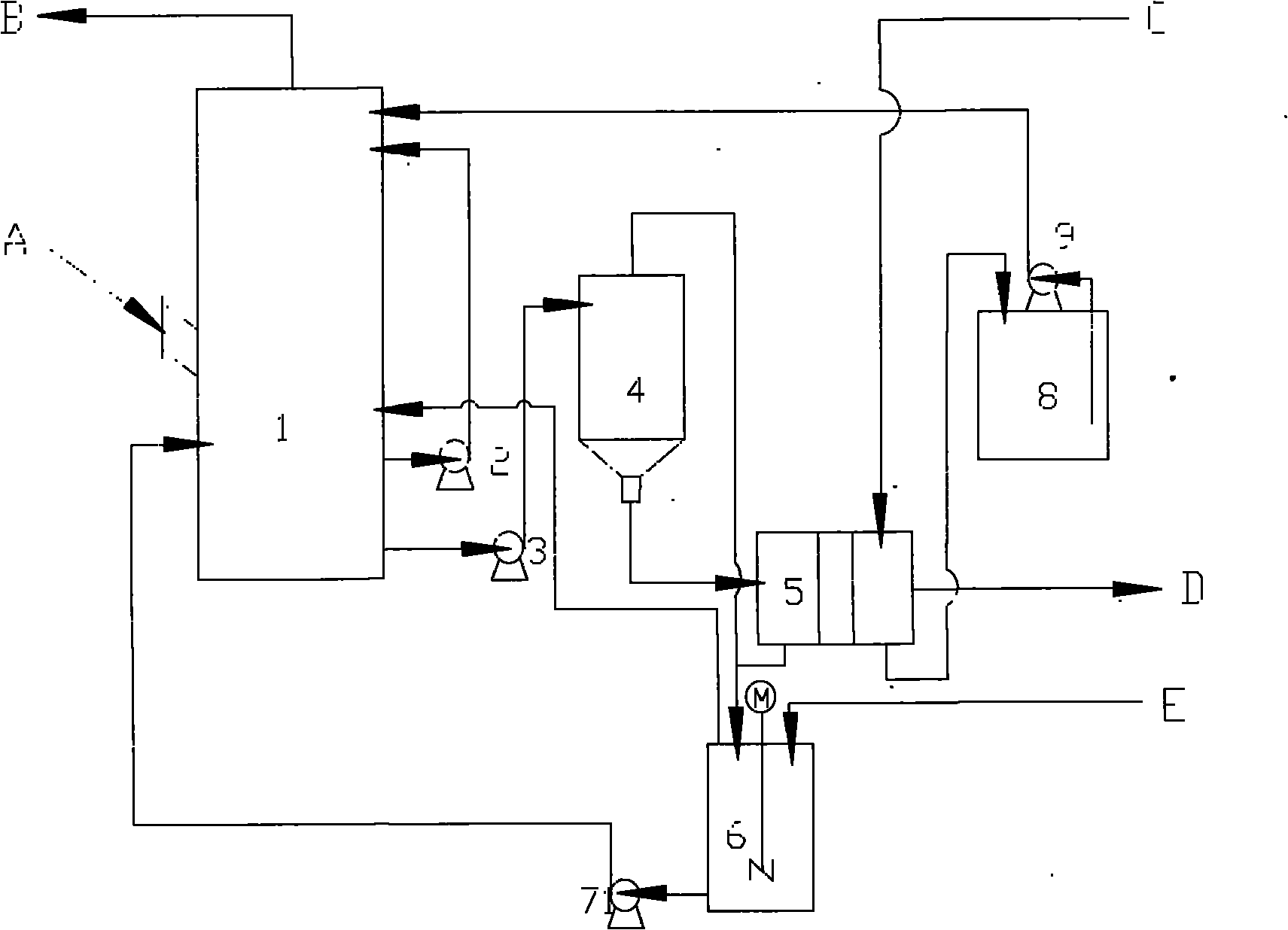

[0031] figure 1 Medium absorption tower 1, circulation pump 2, slurry pump 3, cyclone 4, filter press 5, limestone slurry tank 6, limestone slurry pump 7, washing water tank 8, washing water pump 9. Flue gas A, purified flue gas B, process water C, desulfurization residue (calcium sulfite) D, limestone (calcium carbonate) E

[0032] The flow rate is 200000Nm 3 / h, the flue gas A with a temperature of 150°C first enters the middle part of the desulfurization absorption tower 1, and contacts with the circulating liquid sprayed from the upper part. The concentration of ammonium sulfate in the circulating liquid is 20% (mass fraction), and the slurry at the bottom of the tower passes through the slurry Pump 2 realizes circulation, and the circulating slurry volume is 480m 3 / h; after limestone E is made into 10% (mass fraction) slurry in limestone slurry tank 6, it is driven into the absorption tower with limestone slurry pump 7, and by spraying and washing, sulfur dioxide and d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com