Sensor element having multi-part diffusion barrier

A sensor element, diffusion barrier technology, used in instruments, scientific instruments, measuring devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

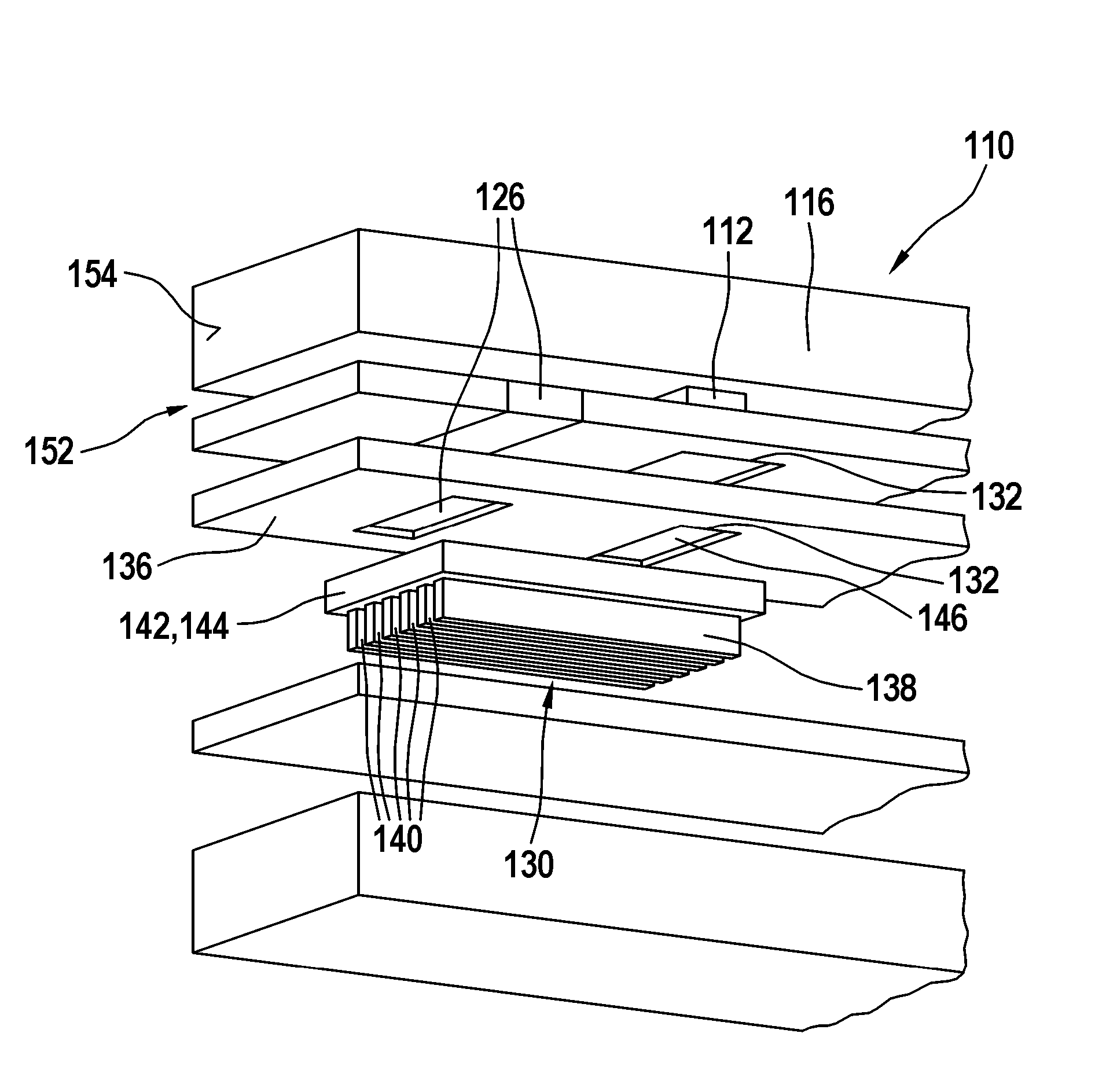

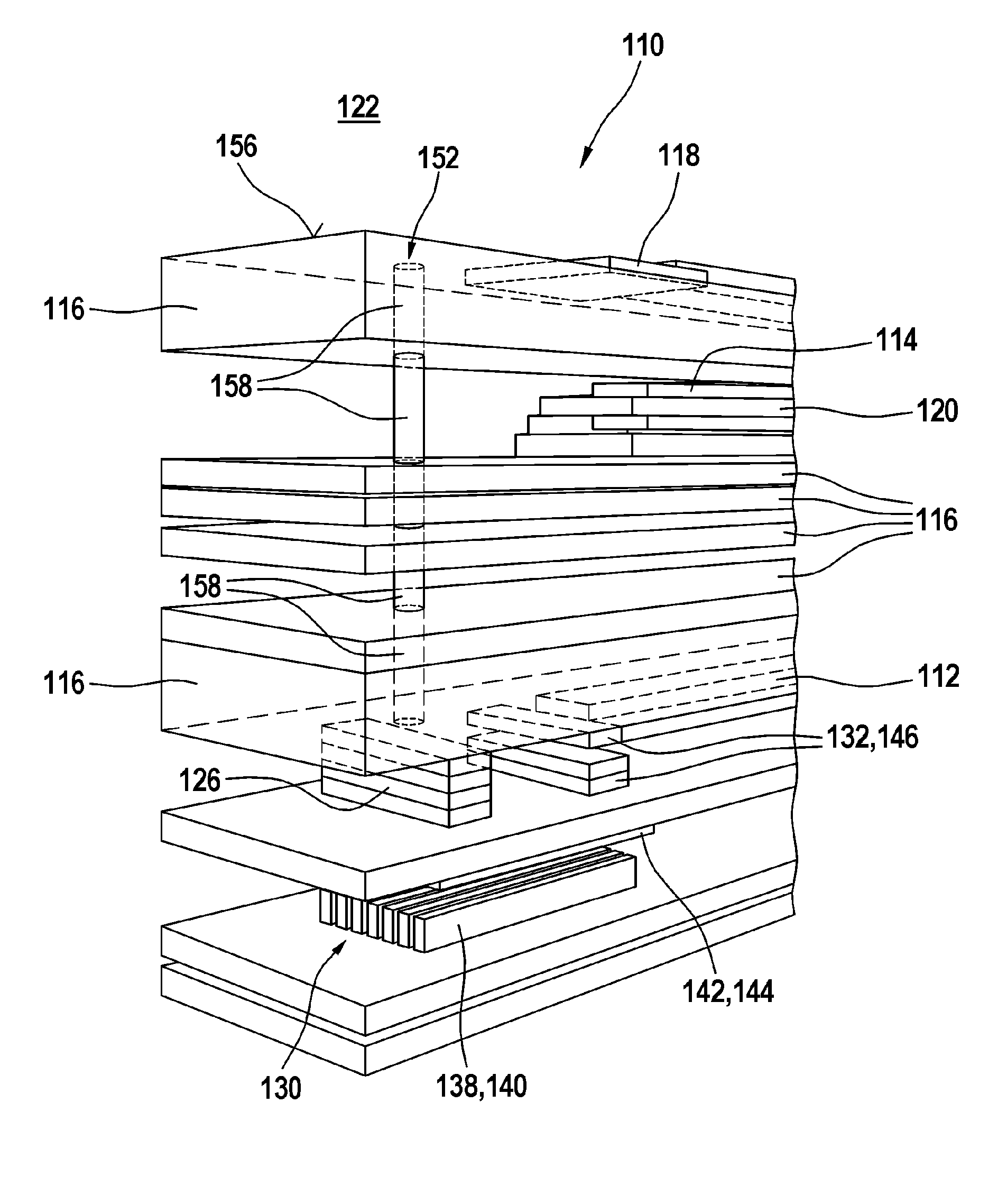

[0029] figure 1 and 2A first exemplary embodiment of the sensor element 110 according to the invention is shown in different schematic diagrams. This is an exemplary embodiment of a broadband oxygen sensor. For further details of such broadband oxygen sensors and the mode of operation of such oxygen sensors, reference is made, for example, to the prior art already mentioned above or, for example, to DE 10 2006 062 060 A1. This is a limiting current-lean mixture sensor with a well-defined characteristic curve. The sensor element 110 has a layer structure with a first electrode 112 , a second electrode 114 and a solid electrolyte 116 , such as yttrium-stabilized zirconia, which connects the two electrodes 112 , 114 . In the exemplary embodiment shown, the two electrodes 112 , 114 are arranged in the same level. In principle, however, other arrangements are also conceivable, such as arrangements with electrodes 112 , 114 one above the other, in which the electrodes 112 , 114 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com