MEMS Jetting Structure For Dense Packing

A fluid jetting, integrated circuit technology, applied in jetting device, inking device, printing, etc., can solve problems such as reducing the area of bare chips

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

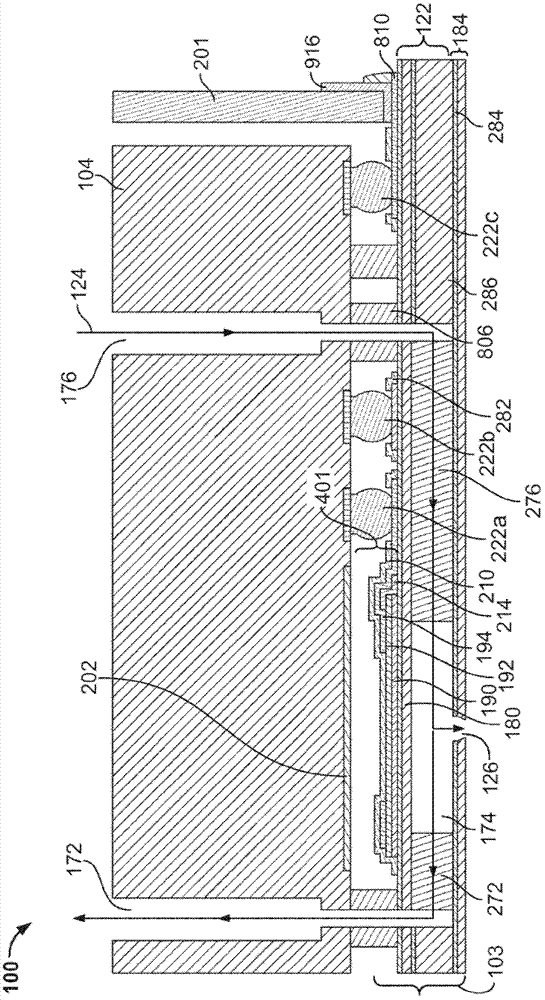

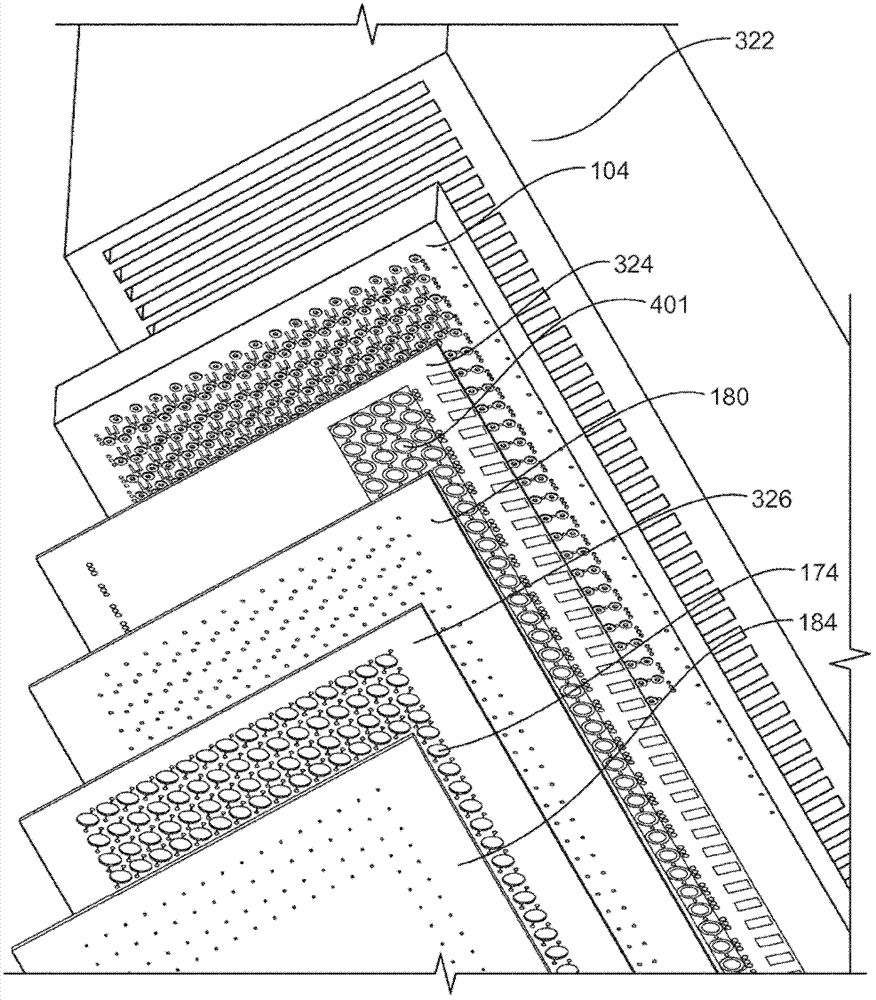

[0050] In fluid droplet ejection, such as digital inkjet printing, high speed and low cost printing are desired while avoiding inaccuracies or defects in the printed image. For example, by reducing the distance the fluid volume needs to travel from the pumping chamber to the nozzle, by having a layer separate from the die that includes the electrical connections to control the ejection of fluid from the actuators in the die, each electrical connection Low cost fluid ejectors can form high quality images at high speeds by placing the injectors adjacent to corresponding fluid ejection elements, and by including fluid inlet channels and fluid outlet channels in the housing instead of the die.

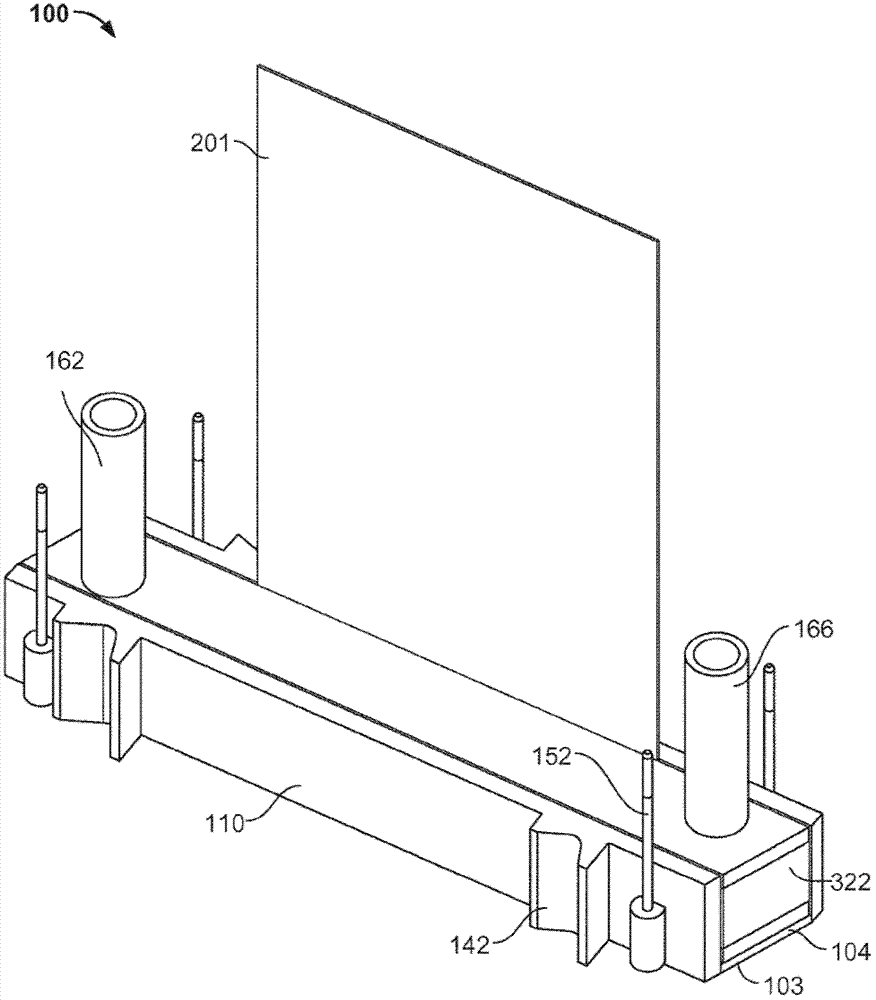

[0051] refer to figure 1 , the exemplary fluid ejector 100 includes a fluid ejection module, such as a printhead module in the shape of a quadrilateral sheet metal, which may be a die 103 fabricated using semiconductor processing techniques. The fluid ejector further includes an integrate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com