A material for coating iron ore pelletizing disks and drums and a constructive arrangement for pelletizing disks and drums

A granulation, disc technology, applied in the direction of metal material coating process, coating, etc., can solve problems such as lack of proper performance, increase of fine particles, cracks, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

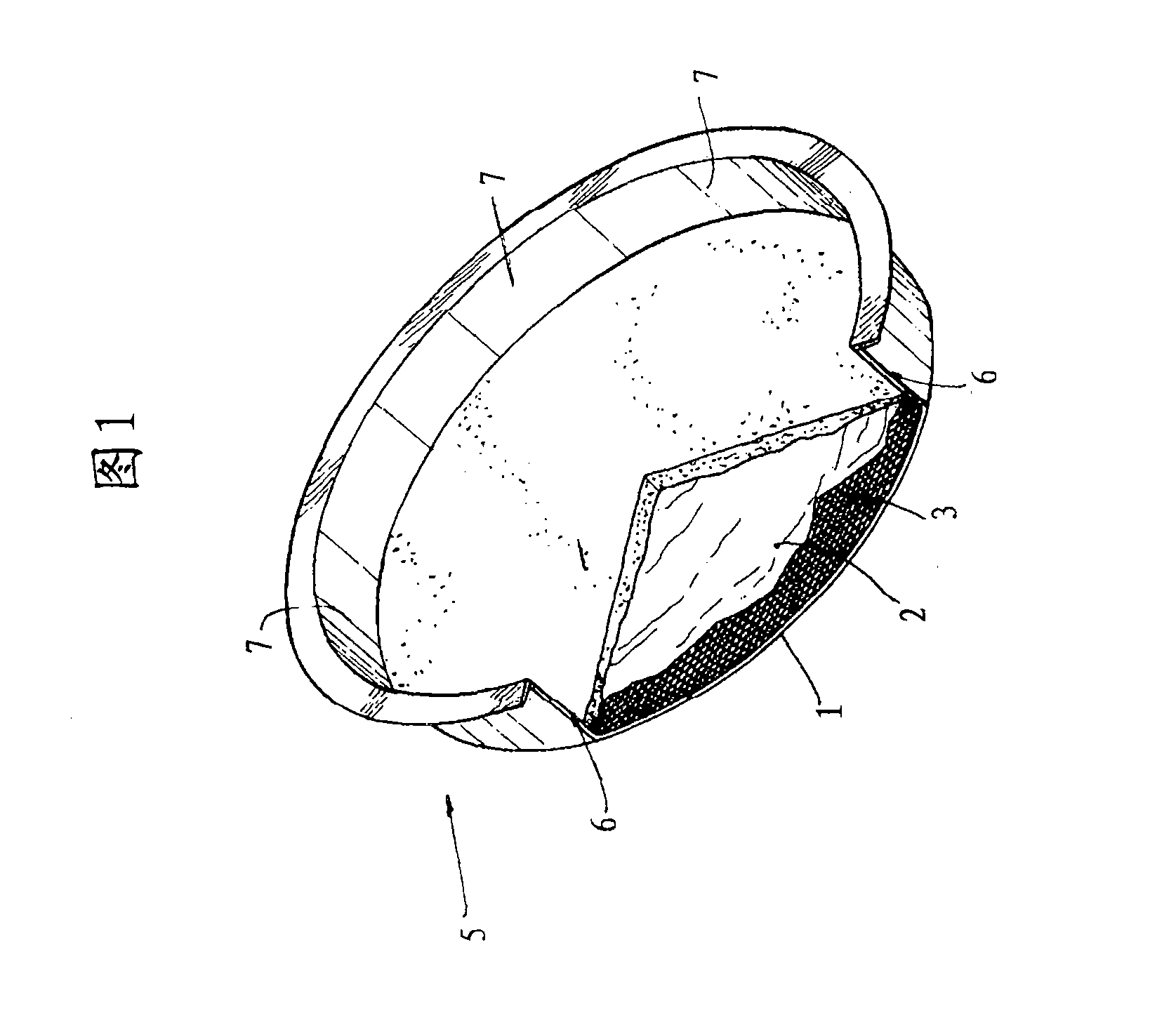

[0023] Among the possible options for applying the material, two can be described here: one, the material is conformably arranged on the surface of the side and bottom layers of conventional and usual granulation discs or drums (4), so that part of the final mixture Sprayed onto said surface, the final mixture consists of a binder and an ore selected from the group consisting of iron ore, manganese ore ores, optionally including a flux, so that the final material comprises a fine surface layer which Contains regular ore on the bottom and sides and the above mixture sprayed on it.

[0024] In the second option and according to the diagram, the material used to coat the iron ore granulation discs and drums consists of a mixture of binder and iron ore, manganese ore or any other ore used in the granulation process, so The mixture may also optionally contain a flux.

[0025] Thus, the present invention also relates to a configuration for a granulation disc and a drum in which the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com